Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

01.06.2017 | Story

Air Cushion Seals being Automated

New vehicles are supposed to save fuel and emit less carbon dioxide. Levitex from Freudenberg Sealing Technologies can efficiently support automakers in their pursuit of these goals. The mechanical face seal, which uses a cushion of air in its operation, heads into series production in 2018.

The Levitex mechanical face seal comes very close to a friction-free crankshaft sealing. That is a positive development since friction at the interface between the engine and the transmission should be as low as possible. Levitex achieves this by using the ambient air around the rotating crankshaft. It produces an air-cushion effect, enabling the crankshaft to rotate friction-free. This helps to save fuel and reduce carbon dioxide emissions – ideally up to a gram per kilometer driven.

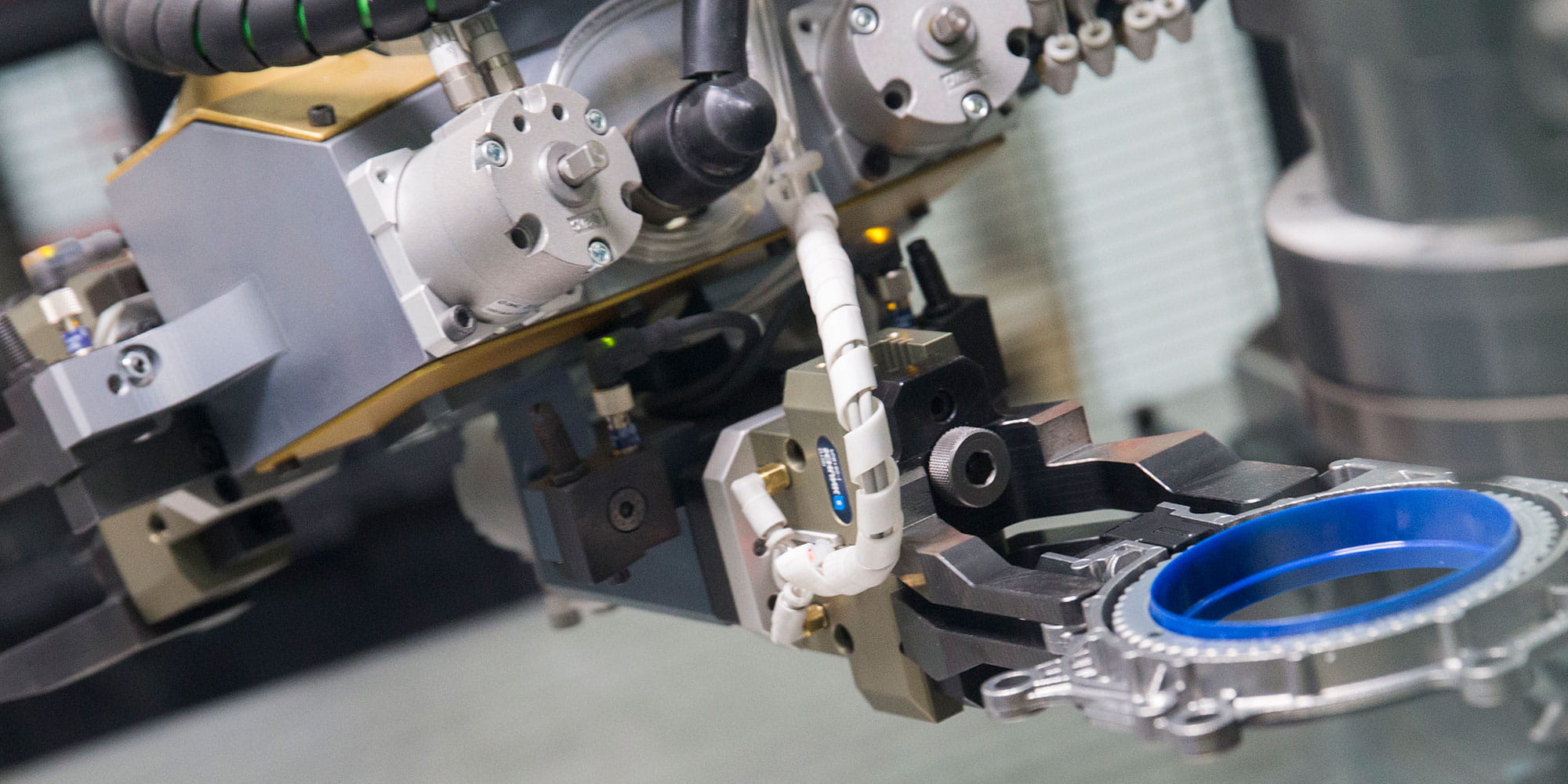

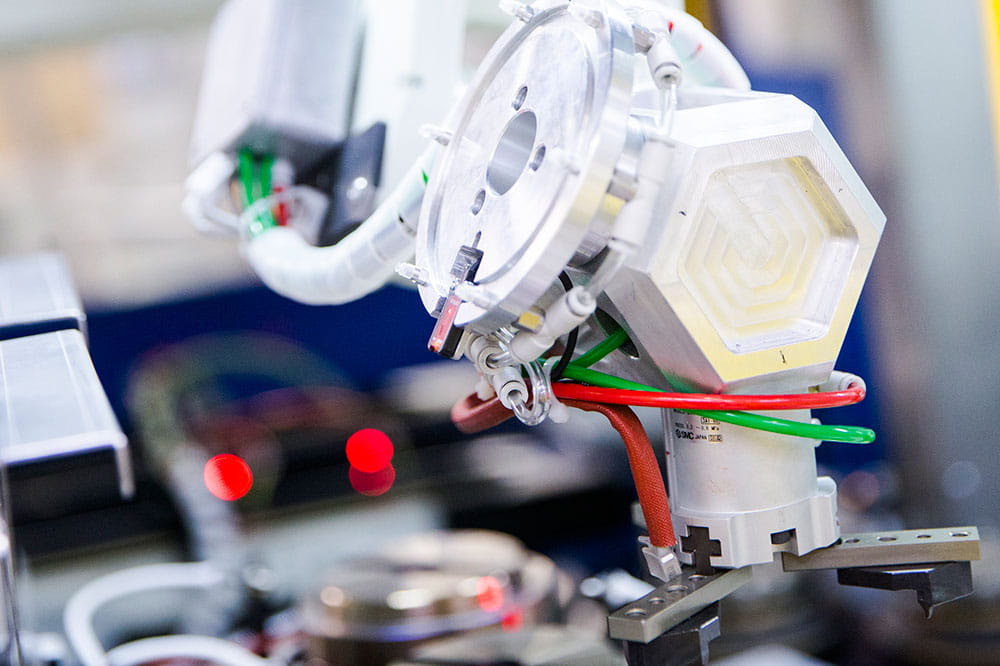

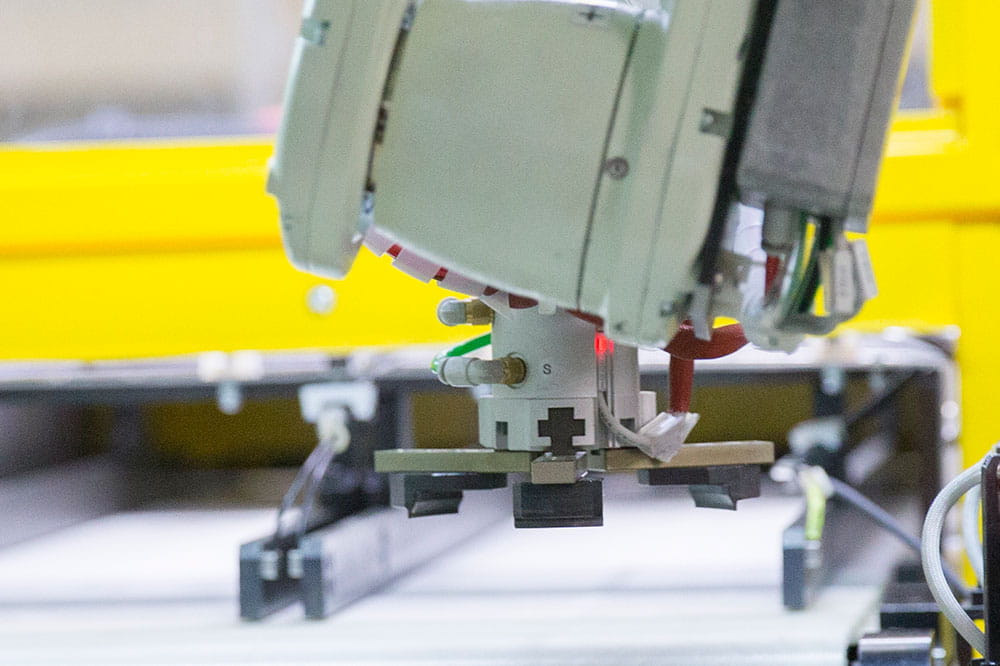

High degree of automation and painstaking quality control

Freudenberg Sealing Technologies (FST) is launching the series production of the new mechanical face seal at its plant in Pinerolo, Italy, in 2018. One goal in the production of Levitex is to achieve the greatest possible degree of automation. In 2016, FST began manufacturing Levitex in a prototype facility. The production process consists of a total of seven stations and contains multiple quality checks. This is imperative since the composition of the materials must be exactly right and the later form must be precisely adhered to. That’s why laser sensors monitor the process after each station, a white light interferometer checks the ring surface, and the leak tightness of the ring is measured at the end.

Modular Production: Easier to Meet Customers’ Wishes

One characteristic of the largely automated Levitex production process relates to its production modules, which function separately. FST Engineer Francesco Scarano described the advantages of this production line: “Each individual module can carry out its respective work step in the best possible way. This allows the technically sophisticated seals to be manufactured with a comparatively simple architecture.” At the end, all the mechanical face seals are given a serial number, which is applied by a laser and which makes it possible to track them individually.

This allows the technically sophisticated seals to be manufactured with a comparatively simple architecture.

The number allows conclusions to be drawn about individual product characteristics, including geometry, surface finish, production date and weight. With modular production, Freudenberg Sealing Technologies can also handle customers’ desires in an uncomplicated way. “The seal rings that we are now bringing to series readiness are equipped with an additional sensor that relays a position-sensing signal electrically to the engine control unit,” Scarano said. The antistatic area required for the production can be integrated into the modular manufacturing approach without difficulty.

Starting in 2018, Levitex seals are due to be deployed in a European automaker’s new engine generation. They will make a contribution to a reduction in the vehicles’ fuel consumption and their carbon dioxide emissions – two characteristics of Levitex that are likely to interest other manufacturers as well.

More news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new