Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

12.03.2015 | News

Overcoming resistance

New film shows sealing solutions for hammer drills and impact hammers

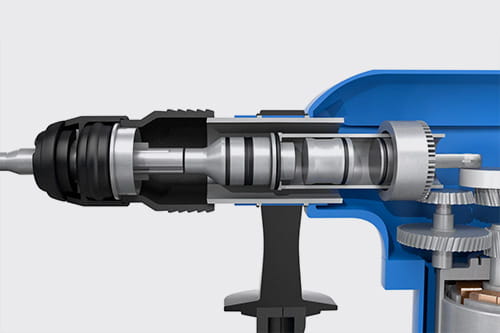

Weinheim. Sealing solutions and innovative molded parts from Freudenberg Sealing Technologies (FST) perform their demanding tasks in hammer drills and impact hammers. Whether for drilling, chiseling, tearing down or stripping, they use their full penetrating power to overcome even the toughest resistance, completely indifferent to whether the material is concrete or stone. This is impressively displayed in a new film about power tools on the FST YouTube channel. They show and describe individual products and their mode of operation within the tool.

“With this short film, we demonstrate that we can completely seal hammer drills and demolition hammers,” said Global Segment Director Achim Ströhle. “Our parts are extremely robust, wear-resistant and reliable long-term. We employ special materials as well as special designs to accomplish this.”

For example, an innovative dust cap design keeps out dirt and dust with several wiping edges.

Special impact cams provide damping during wall breakthroughs, protect components and prevent damage. “That means we offer optimal operational safety for people and machines – even under difficult operating conditions,” Ströhle said.

The foundation of the sealing products is always first-class, PAH-compliant materials – developed and produced at FST. “In this way, we have the perfect material for each application – made-to-order for the customer,” Ströhle said.

Striker seals ensure that no dust penetrates into the gearbox and that no lubricant escapes. This increases the gearbox’s expected life span.

In return, striker wipers substantially protect components against contamination. “The standard material for striker wipers is HNBR,” Ströhle explained. If a component is going to be used in an especially demanding environment, Freudenberg can also produce striker wipers composed of a new, extremely wear-resistant polyurethane at the customer’s request.

The new T-ring seal rounds out the line-up. It seals reliably with up to 80 percent less friction than O-rings. The result: reduced energy needs during operation. There is a choice between HNBR or – depending on the application – high-temperature-resistant FKM as the material.

“Incidentally, we have jointly developed damping elements and absorbers with our customers, for which Freudenberg New Technologies handled the product calculations,” Ströhle added. The bottom line: significantly reduced development times – and lower costs.

The film shows that all FST parts have one thing in common: They are “often invisible, always essential.”

Overcoming the toughest resistance with full penetrating power

Whether against concrete or stone: hammer drills and demolition hammers literally have a huge impact. Sealing solutions and rubber molded parts from Freudenberg Sealing Technologies are meanwhile essential to them. They robustly and reliably guarantee the machine’s power output and a long lifetime of drilling, chiseling, demolishing and stripping.

More news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.