Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

24.11.2014 | News

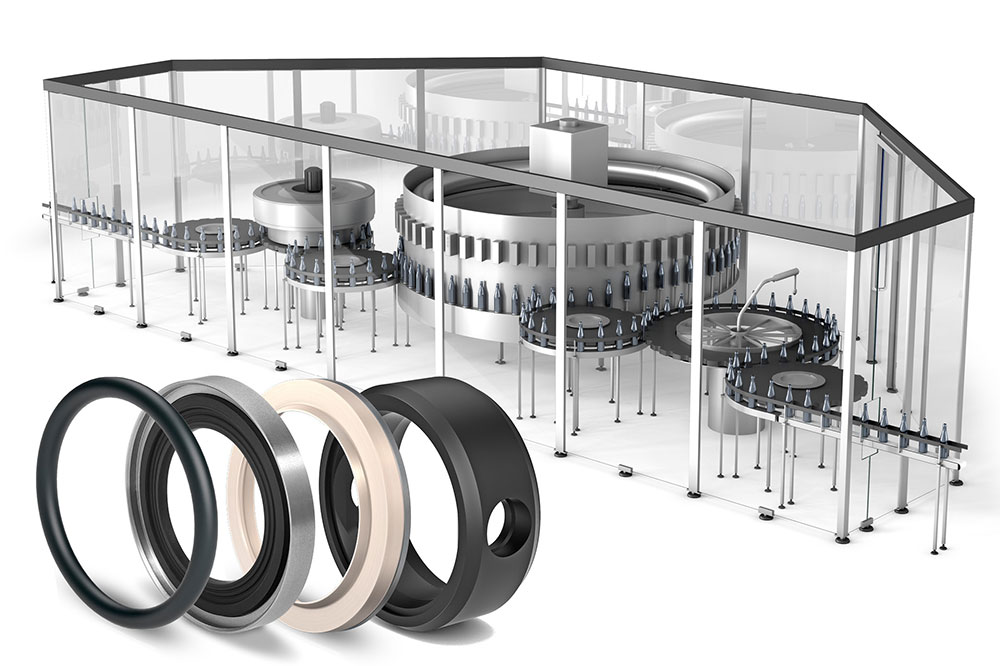

HDR-2C

The advantages of the new rod seal HDR-2C from Freudenberg Sealing Technologies (FST) include special extrusion stability in the high-pressure range and great flexibility down to a temperature of –50 °C, thanks to an innovative material combination of two different polyurethanes.

Seals in hydraulic cylinders have to withstand substantial loads. They are exposed to severe pressure and temperature fluctuations as well as the hydraulic media that are used. The individual sub-areas of the rod seals must also meet different requirements that to some degree require contradictory material properties. At the same time, they should guarantee reliable sealing over the entire lifetime and a broad spectrum of performance. HDR-2C's two-component technology takes the loads on the rod seal's various functional areas into account by combining the advantages of two high-performance materials with different physical properties into just one element.

The seal back of FST U-rings consists of polyurethane 98 AU 928, a material with a Shore hardness of 98 A, which stands out for its extreme stability even under high operating pressures. Its seal lips made of polyurethane 92 AU 21100 have very good dynamic sealing properties due to the material's high elasticity and low compression remainder. Compared to the standard seal, the HDR-2C's two-component technology offers a significantly improved performance range. Greater gap tolerances, reliable use under operating pressures up to 500 bar and excellent leak tightness in the temperature range of –50 °C to +110 °C make the new Freudenberg Sealing Technologies rod seals an extremely high-performance sealing solution with outstanding value for the price.

More news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.