Quantix® ULTRA

Quantix® ULTRA – Revolutionizing Fire Protection in High-Tech Industries

Quantix® ULTRA is a state-of-the-art flame-resistant polymer material designed to enhance safety and performance across multiple verticals. This advanced material offers outstanding thermal stability, superior mechanical strength, and versatile design capabilities, positioning it as an optimal solution for high-technology sectors such as e-mobility, aerospace, aviation, and energy storage. With its unique properties and competitive advantages, Quantix® ULTRA sets a new standard in fire protection and material performance.

Key Features & Benefits

Extreme Flame Resistance

Quantix® ULTRA can withstand temperatures up to 1200 °C for over 30 minutes without melting. This exceptional flame resistance makes it ideal for fire-critical applications, ensuring that the material maintains its integrity and functionality even under extreme thermal conditions. This capability is particularly valuable in environments where fire safety is paramount.

Dimensional Stability

One of the standout features of Quantix® ULTRA is its ability to maintain shape and function during thermal events. This dimensional stability ensures that the material does not deform or lose its structural integrity when exposed to high temperatures. This property is crucial for applications that require precise and reliable performance.

Lightweight & Durable

Quantix® ULTRA is less than half the density of aluminum, making it an excellent choice for applications where weight reduction is essential. Despite its lightweight nature, the material is incredibly durable, offering high mechanical strength and resistance to wear and tear. This combination of lightweight and durability contributes to energy efficiency and extended service life.

Electrically Insulating

The material's electrically insulating properties prevent arcing and protect sensitive components from electrical interference. This feature is particularly important in applications involving high-voltage systems, where electrical insulation is critical to ensure safety and prevent malfunctions.

Customizable

Quantix® ULTRA supports complex 3D geometries and multifunctional integration, allowing for a high degree of customization. This flexibility enables engineers and designers to create intricate and specialized components tailored to specific application needs. The material's adaptability makes it suitable for a wide range of industries and applications.

Sustainable

Quantix® ULTRA has a low Life Cycle Assessment (LCA) emission factor, using carbon monoxide as a feedstock and generating minimal production waste. This sustainability aspect aligns with the growing demand for environmentally friendly materials and practices. By reducing its environmental impact, Quantix® ULTRA supports sustainability goals and contributes to a greener future.

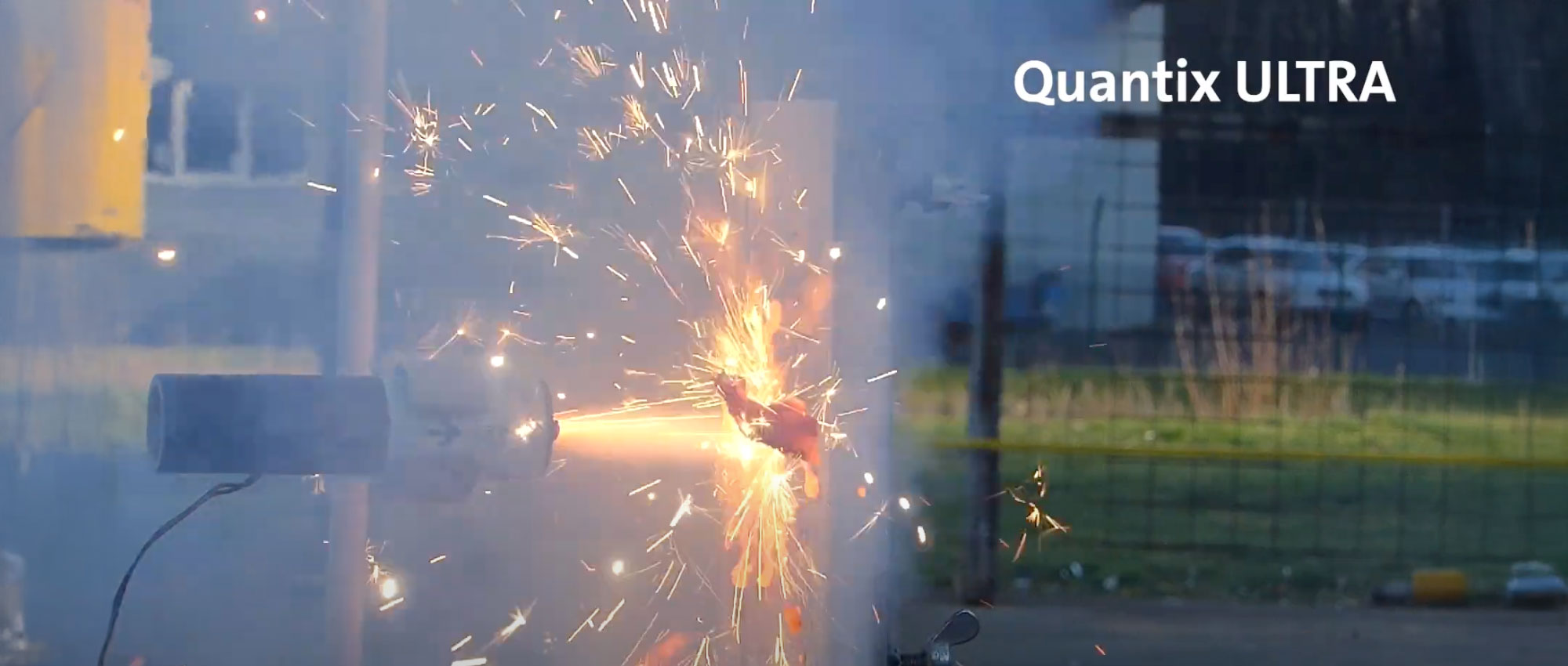

Flame Resistance and Direct Exposure Test

Competitive Advantages

-

Outperforms Standard FR Thermoplastics

Quantix® ULTRA does not melt or lose function under flame exposure, making it superior to standard flame-retardant thermoplastics. This advantage ensures that the material remains effective and reliable in fire-critical applications, providing enhanced safety and performance.

-

Replaces Aluminum

Quantix® ULTRA offers better design flexibility, lower weight, and longer thermal endurance compared to aluminum. This replacement capability allows for more innovative and efficient designs, reducing overall weight and improving energy efficiency in various applications.

-

Faster Time-to-Market

Quantix® ULTRA is compatible with standard injection molding processes, eliminating the need for post-processing. This compatibility accelerates the production timeline, enabling faster time-to-market for products utilizing this material.

-

Proven Reliability

Quantix® ULTRA has demonstrated its reliability and effectiveness in demanding applications, showcasing its superior performance and durability. This proven track record enhances the material's credibility and attractiveness for adoption in various high-tech industries.

Material Test with Simulated Exhaust Conditions

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new