Hydropower

Empowering Hydropower with Innovative Sealing Solutions

The hydropower industry is navigating a complex landscape filled with regulatory hurdles, environmental concerns, and evolving technological demands. At Freudenberg Sealing Technologies, we understand these challenges and are committed to providing innovative solutions that drive sustainability and efficiency. Our approach leverages cutting-edge technology and a deep understanding of market needs to develop tailored sealing solutions that enhance performance and reliability. By staying ahead of industry trends and continuously adapting to changes, we turn challenges into opportunities, ensuring that our clients can meet and exceed market demands. This proactive stance allows us to deliver exceptional value and drive success for our clients and stakeholders alike.

Sealing and Guiding Solutions Built for Turbine Demands

In every hydropower plant, seals, guides, and sliding bushings are critical to reliable turbine operation. With more than two decades of experience in the hydropower sector, we specialize in the development and manufacturing of precision sealing and guiding systems tailored to the unique demands of water-driven energy. Our solutions replace outdated leather and fabric-reinforced seals with high-performance, machined alternatives—engineered to match the specific media and mechanical conditions of each application. Whether operating in clean water or abrasive environments like glacier-fed systems, our durable material pairings ensure long-lasting performance, reduced maintenance, and maximum efficiency.

Kaplan turbine

The Kaplan turbine is a highly efficient axial-flow reaction turbine designed for low-head, high-flow hydropower applications. It features adjustable runner blades and wicket gates, allowing it to maintain optimal efficiency across a wide range of flow conditions. This adaptability makes it especially suitable for river-based and tidal power plants, where water levels and flow rates can vary significantly.

Water enters the turbine through a spiral casing and is directed by adjustable guide vanes toward the runner. The runner blades, which can pivot during operation, respond dynamically to changes in flow, ensuring consistent energy conversion. This dual-adjustment mechanism—of both guide vanes and runner blades—enables the Kaplan turbine to achieve high efficiency even under partial load conditions.

From a sealing perspective, Kaplan turbines present unique challenges due to their continuous blade adjustment and exposure to abrasive media such as sediment-laden or glacier-fed water. Hydraulic systems used to control blade pitch require robust sealing solutions that can withstand high pressures, oscillating motion, and contamination. Components such as rod seals, piston seals (like the OMK-PU 30500), guide rings, and wipers must be engineered for durability, low friction, and resistance to hydrolysis and wear.

Kaplan turbines are a cornerstone of modern low-head hydropower generation, combining mechanical sophistication with operational flexibility. When paired with advanced sealing technologies, they deliver reliable, long-term performance in some of the most demanding environments in renewable energy.

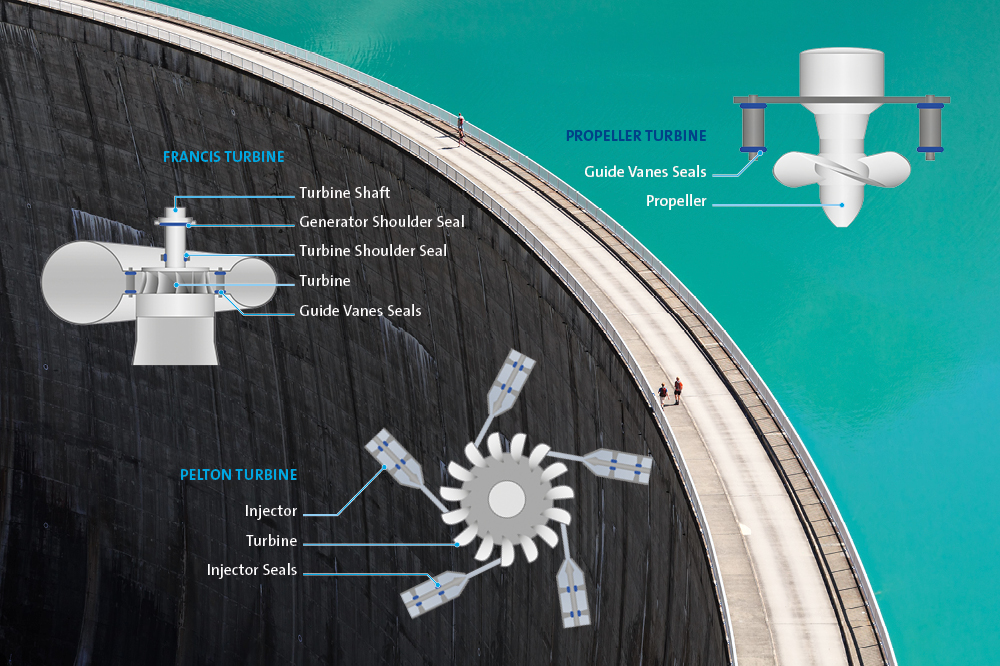

More Turbine Applications

In addition to Kaplan turbines, our sealing solutions are widely used in other hydropower turbine designs such as Francis, Pelton, and Propeller turbines. These configurations, each optimized for specific head and flow conditions, benefit from our robust sealing technologies that ensure long-term reliability and efficiency. Whether managing high-velocity jets in Pelton turbines or the mixed-flow dynamics of Francis turbines, our seals are engineered to withstand extreme pressures, minimize leakage, and support sustainable energy generation across diverse hydropower environments.

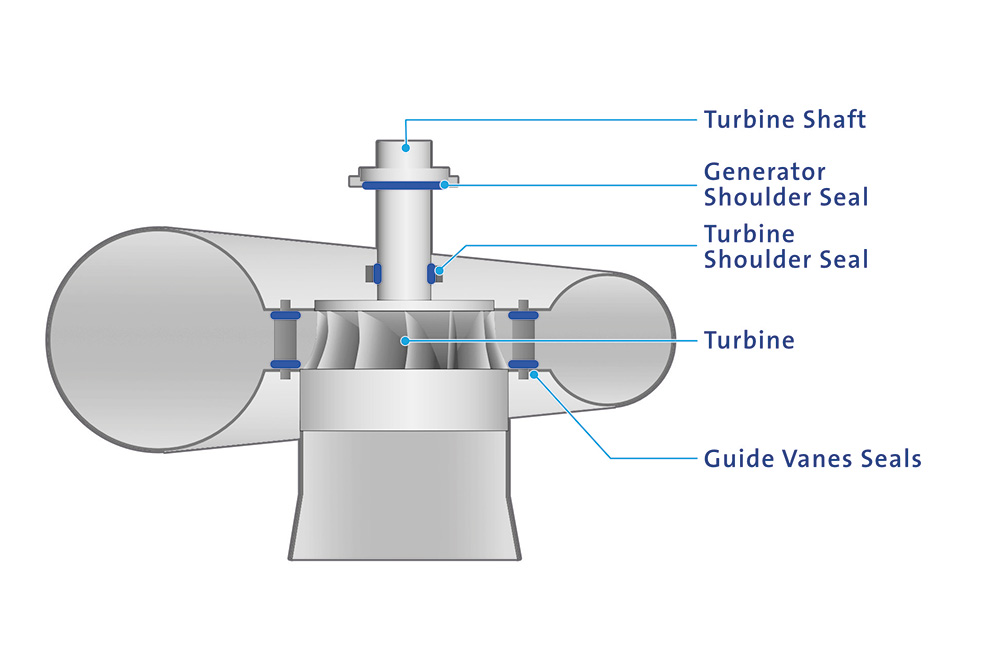

Francis turbine

Francis turbines are the most widely used type of reaction turbine, ideal for medium-head and high-flow applications. Water enters the turbine radially and exits axially, passing through a spiral casing and adjustable guide vanes that control flow. Their robust design and high efficiency across a broad operating range make them a reliable choice for base-load hydropower plants.

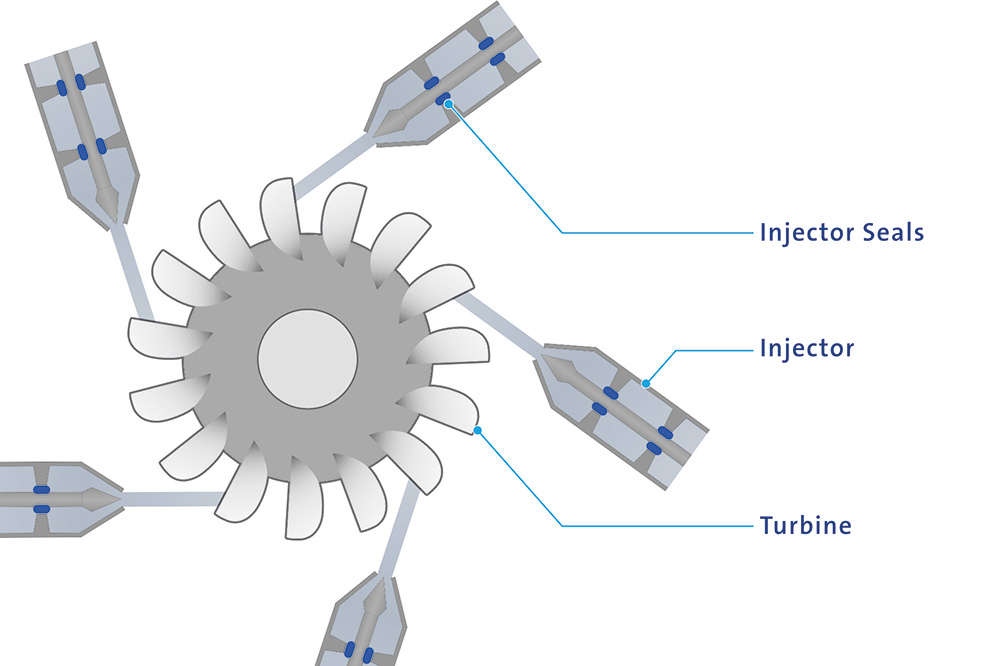

Pelton turbine

Pelton turbines are impulse turbines designed for high-head, low-flow conditions. They operate by directing high-velocity water jets onto spoon-shaped buckets mounted around the runner. This design converts kinetic energy into mechanical energy with minimal energy loss, making Pelton turbines ideal for mountainous regions and remote installations.

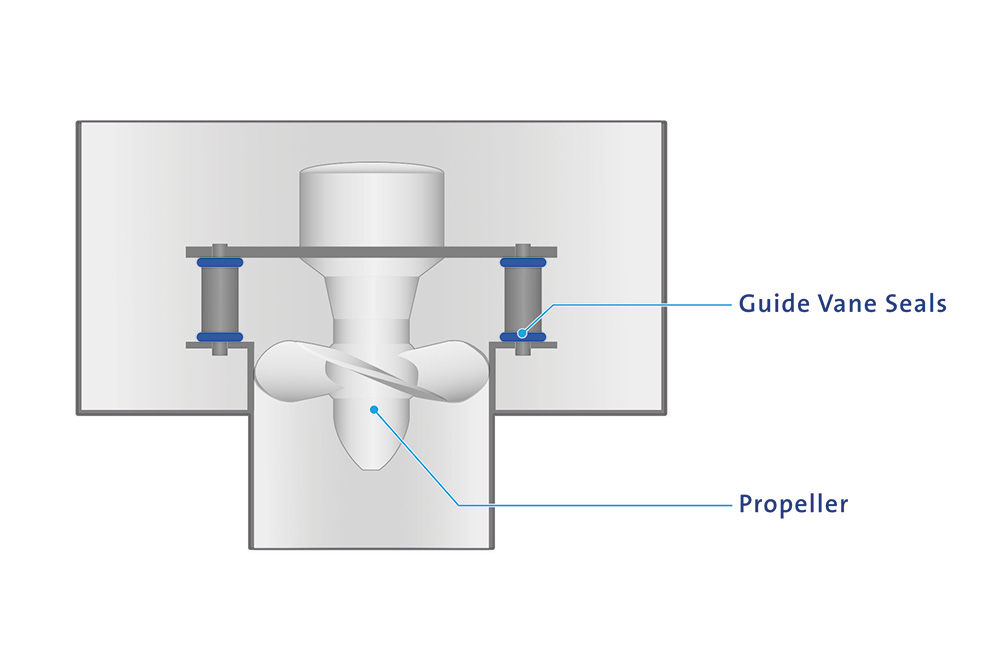

Propeller turbine

Propeller turbines are axial-flow turbines suited for low-head, high-flow environments. Featuring fixed or adjustable blades, they allow water to flow parallel to the shaft, driving the runner efficiently. Their compact design and high flow capacity make them well-suited for run-of-river plants and tidal energy applications.

News & Stories on Hydropower

Service and Support for the Hydropower Market

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new