Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Metal Processing

High Functionality, Reduced Downtime

In the Iron and Steel industry, there are pronounced demands on people, materials and technology. Freudenberg Sealing Technologies provides compact sealing systems that seal reliably – even in extremely harsh conditions – to meet these challenges, as well as high operating life requirements, including temperature, stroke, speed, pressure, friction, duty cycle, radial force and lubricants.

Our seals contribute to:

-

Better output – benefitting both quantity and quality

-

Lower costs

-

Less downtime

-

Improved performance through longer maintenance cycles

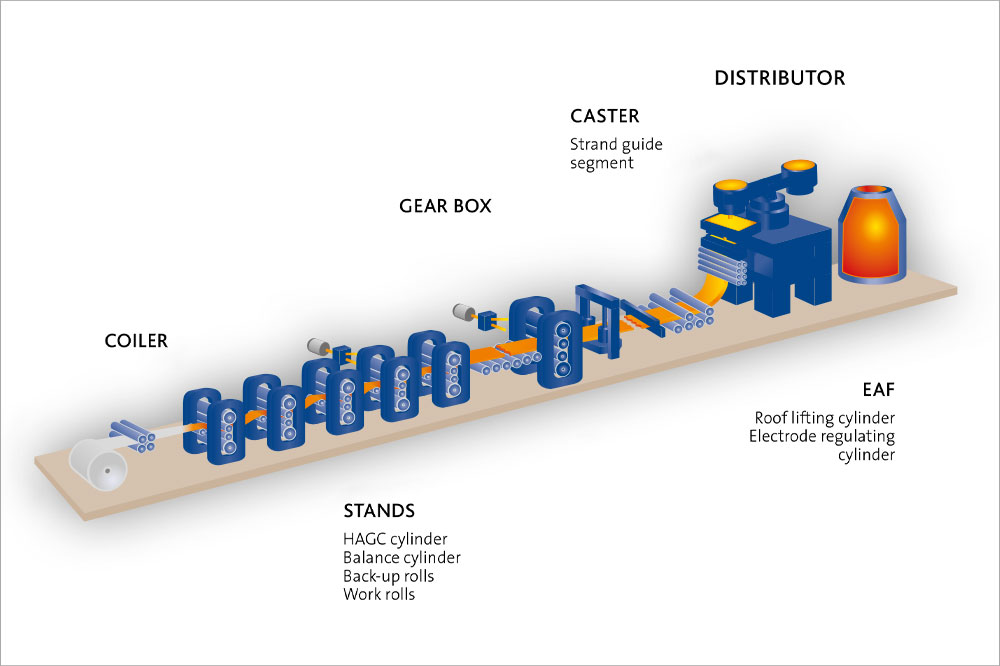

Customers face unique requirements and challenges across their manufacturing operations, including steel mills, finishing lines, continuous casters and rolling mills. Learn more about our specific solutions for Stands, Gearboxes, Casters and EAFs.

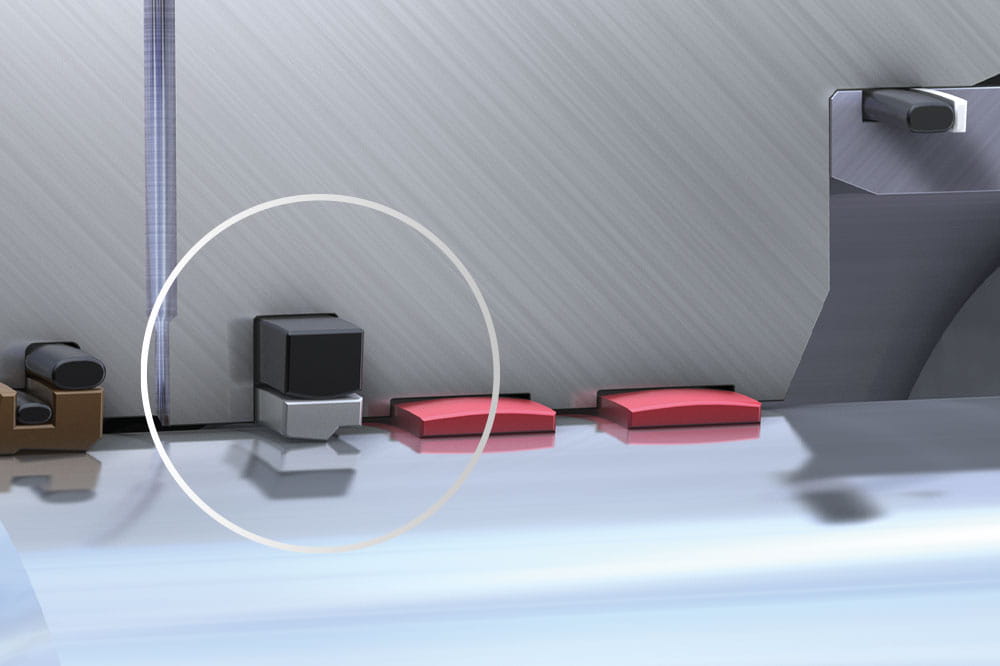

Solutions for Balancing Cylinders and HAGC Cylinders

We offer solutions for maximum control of a short-stroke, high-frequency cylinder, as well as sealing systems that optimize protection for counter surfaces.

The well-matched combination of Freudenberg seals and guide bands prolongs service intervals. Our PTFE glass compound is self-lubricating and is gentle to the surface, which helps reduce maintenance costs.

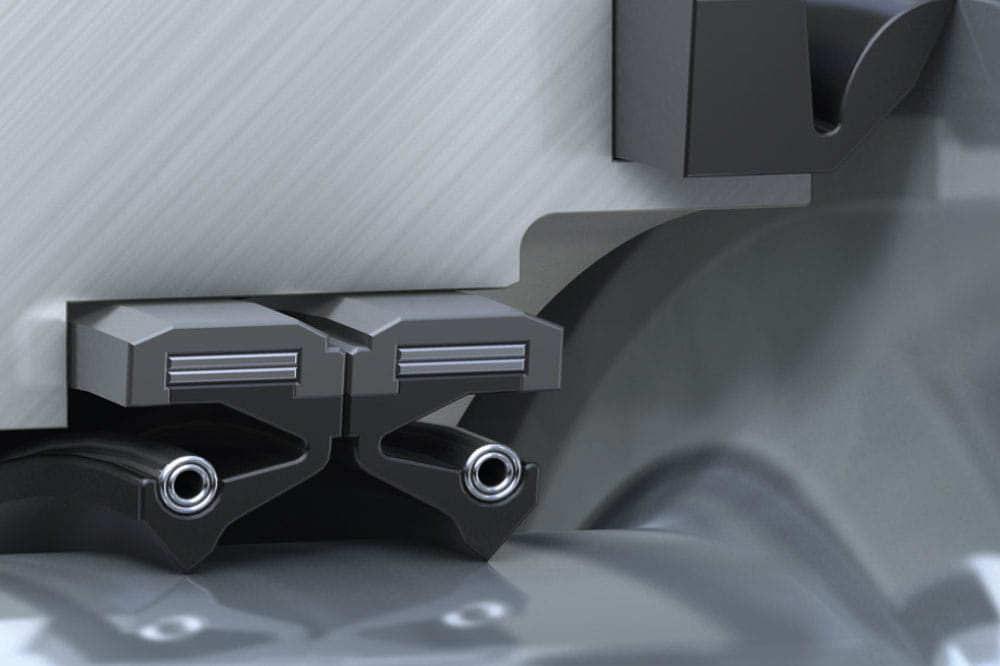

Sealing Systems for Balancing Cylinders

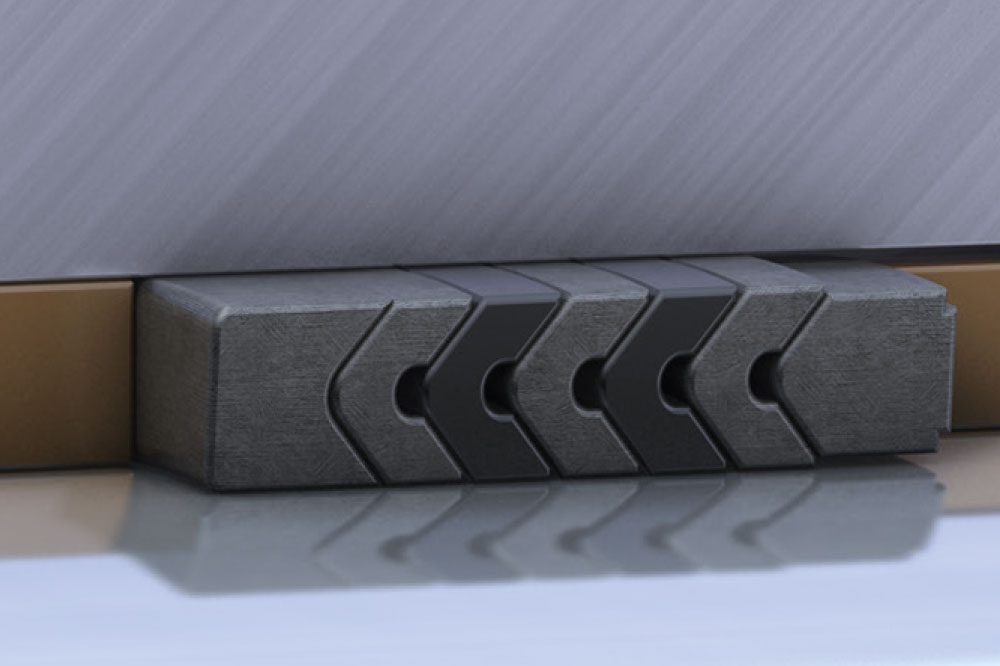

- Superior adjustability and cylinder control, thanks to the advanced frictional behavior of Merkel® Omegat PTFE seals

- The patented Merkel® Guivex geometry enables high loads, while reducing the risk of metal-to-metal contact

- Our unique sealing arrangement helps improve performance and enables shorter housings

Sealing Systems for HAGC Cylinders

We have the expertise to improve the accuracy of HAGC cylinders, while boosting performance, reliability and durability.

- Minimum wear is critical. That’s why we use a self-lubricating PTFE glass compound, which is ideal for short strokes and high frequencies

- Our systems are also very functional, reliably handling high pressures (even above 30 MPa) due the heavy-duty design of the Merkel® Omegat seal, and, simultaneously, offering maximum service life

- External “protective screen” in extremely dirty environments – Merkel® double wiper PT 2 offers the best protection for a long-lasting sealing system

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Discover More on Metal Processing

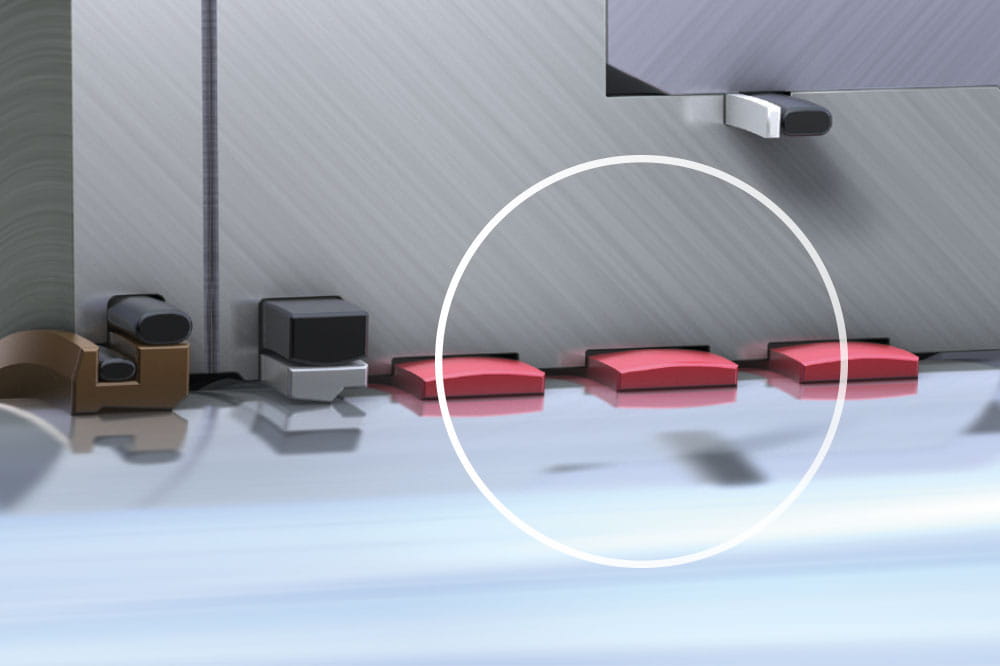

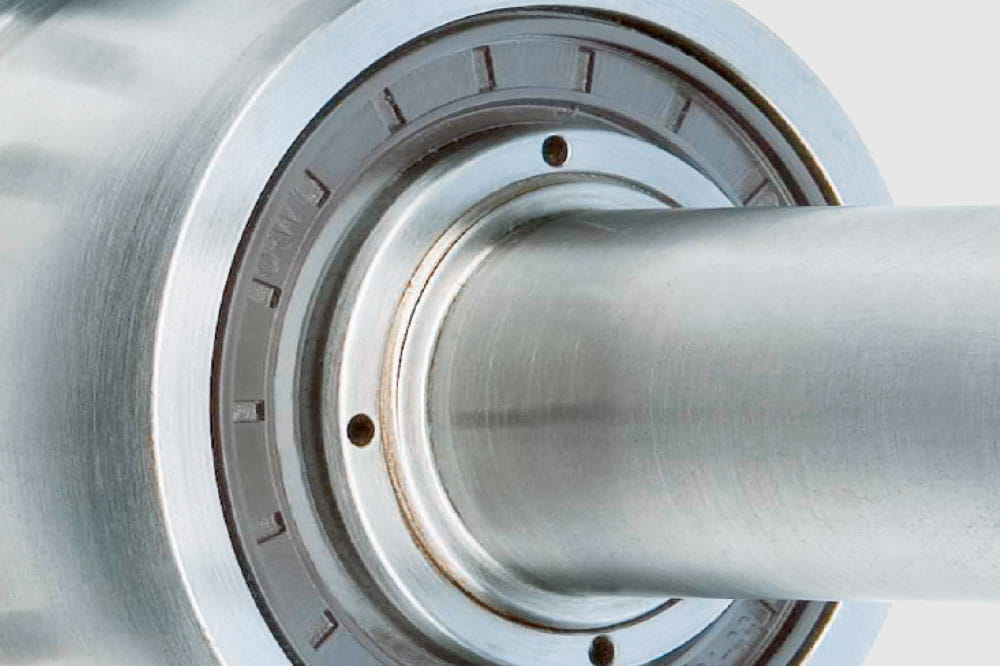

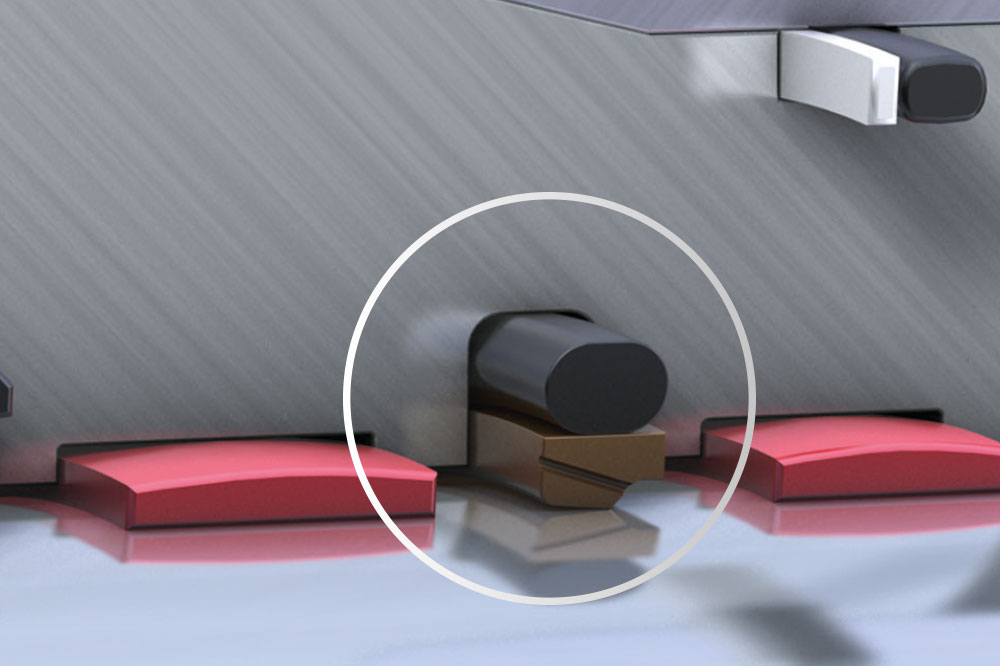

Solutions for Work Rolls and Back-up Rolls

Specially designed for work rolls, Freudenberg’s tailor-made sealing combination (RPM41 + Environmatic) provides secure and reliable sealing. For manufacturing customers, this adds up to maximum tons produced with minimal lost hours to downtime. We know how to increase service life for work rolls.

Our RPM41 + Environmatic combination offers these advantages:

-

Readiness of supply – within hours, if needed

-

Reliable protection against water ingress into lubricant

-

Gentle to the housing – easy to install and remove

-

Eliminates tension spring at the sealing lip for improved operational safety

Further Sealing System for Roller Bearings in Work Rolls

- Operating speeds up to 25 m/s

- Space-saving design utilizes integrated lubrication grooves in the sealing element

- Precise line forces of the sealing edge yields leak-free performance and minimal wear

Sealing Systems for Plain Bearings in Back-up Rolls

- Solid performance – even up to ±3 mm shaft deflection, with speeds up to 35 m/s (40 m/s intermittent)

- Self-retaining fit by vulcanized-in steel bands

- Simple, housing-friendly installation

Maximum Protection for Your Work Roll Bearings

Merkel® Radiamatik RPM41 + Merkel® Envirnomatic

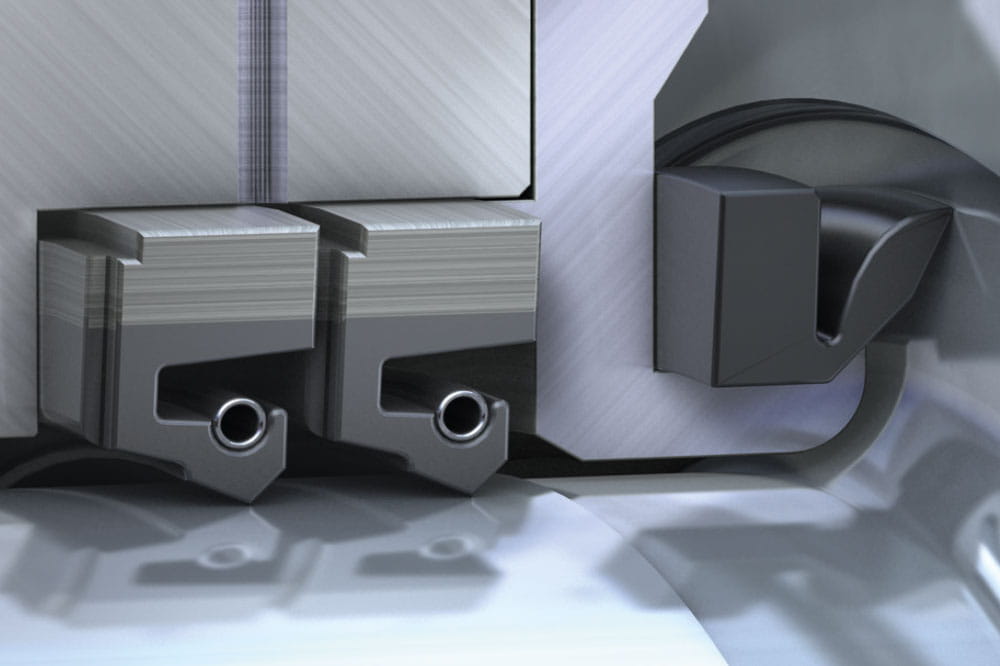

Visit Webspecial open_in_newSealing Systems for Gearboxes

In addition to its original Simmerring® for Gearboxes, Freudenberg offers superior sealing systems for the demanding transitions between the spindle and drive.

Benefits include:

-

A floating cartridge for high axial movements

-

No wear issues

-

No leakage issues

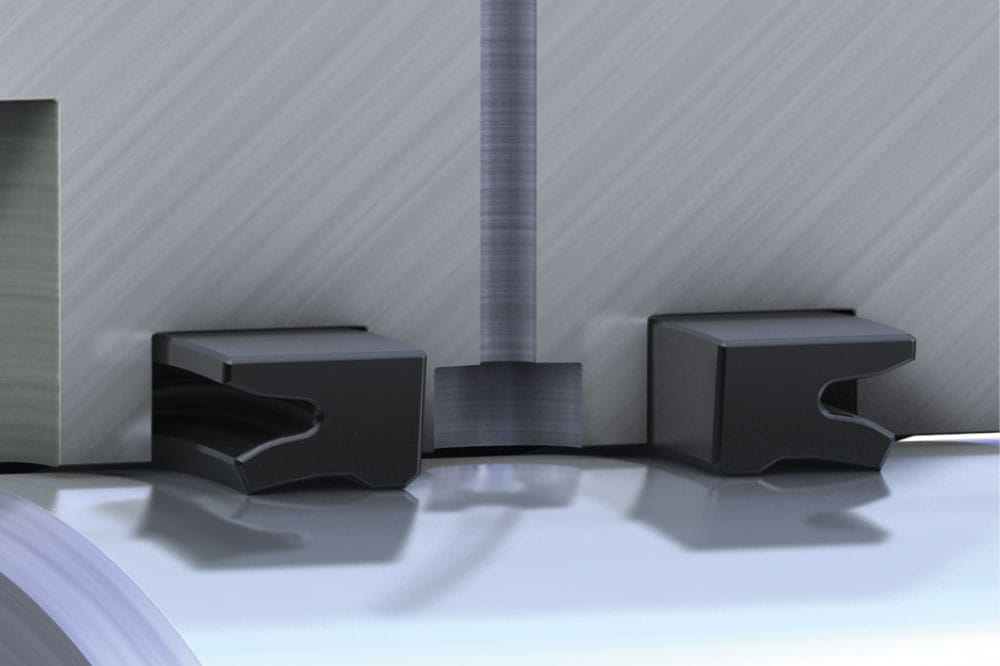

Sealing Systems for Continuous Caster Segments

Simmerring® Type BAUM for Open Housings

- High wear resistance for long service life at high temperatures

- Standard seals are readily available

- Simple installation for low service cost

Simmerring® BAUM with self-retaining fit in the housing. In case of heavy contamination, a protective lip or “filter fleece” is available to help optimize operating life.

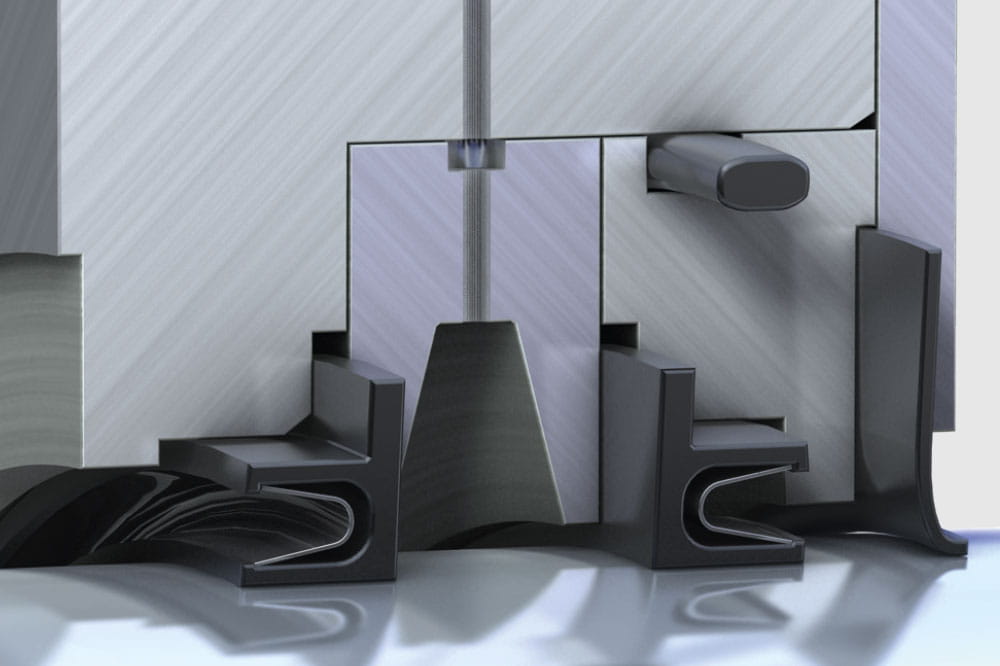

When It Gets Too Hot

- Reliable protection of the bearing against contamination by PTFE wiper

- Suitable for high speeds and high temperatures

- Low friction and greatly reduced wear due to Freudenberg’s self-developed, high- quality PTFE compounds that, in addition to the actual sealing function, also protect the counter surface

Both made of Carbon filled PTFE: Merkel® U-ring NRRW in combination with a Merkel® water guard WADB-9460

Sealing Systems for Electric Arc Furnaces (EAF)

For Easy Replacement

- Long lifetime, even without bellow protection of the rod

- Reliable sealing function, even if the rod is highly strained

- Split version for ease of installation and reduced maintenance cost

For Low Friction and Long-Stroke Performance

Our products are designed to reduce friction loss.

- Stick-slip-free operation allows precise positioning

- Ideal sealing function for long service intervals without leakage

* Important note: The rod must be protected against sparks and similar hazards

Contact Us Today

Our steel and iron industry experts can address all your questions, including:

- Flexible profiles

- Non-standard seal sizes

- Delivery times

- Short- and long-stroke systems

- Emergency services

- On-site troubleshooting capabilities

Together with key partners, Freudenberg provides a wide range of high-quality sealing systems, including complete sealing kits to meet your needs.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new