Data Center Solutions

Components for Liquid Cooling Systems

Data centers are the backbone of modern technology, providing the infrastructure needed to store, process, and manage vast amounts of data. However, they face several challenges, including maintaining optimal temperatures, ensuring reliable power management, and safeguarding sensitive information.

With our experience from automotive applications, our outstanding material knowledge and our application know-how we are your premium partner for any sealing solution for liquid cooling in data centers and common future developments in this rapidly developing arena . Our goal is to help you to improve efficiency, reduce downtime, and enhance the reliability of data center operations.

Data Center Cooling Technologies

Immersion Cooling

- Advanced cooling technology that submerges electronic components in dielectric fluid, ensuring efficient heat dissipation and reducing maintenance costs.

- We supply sealing solutions for all integral components in contact with various kinds of cooling liquids used for immersion cooling as circulation pumps, pipes, busbars, valves, sensors, heat exchangers and pressure relief valves .

- We can be your partner for the next step of data center cooling evolution - two phase immersion cooling (2PIC).

Direct to Chip (D2C) Cooling

- Cutting-edge cooling technology that targets the hottest parts of the chip directly, ensuring optimal performance and preventing overheating.

- We supply proven sealing solutions for all integral components of D2C cooling for data centers as circulation pumps, pipes, connectors, valves, sensors, heat exchangers and pressure relief valves.

Our Products in Detail

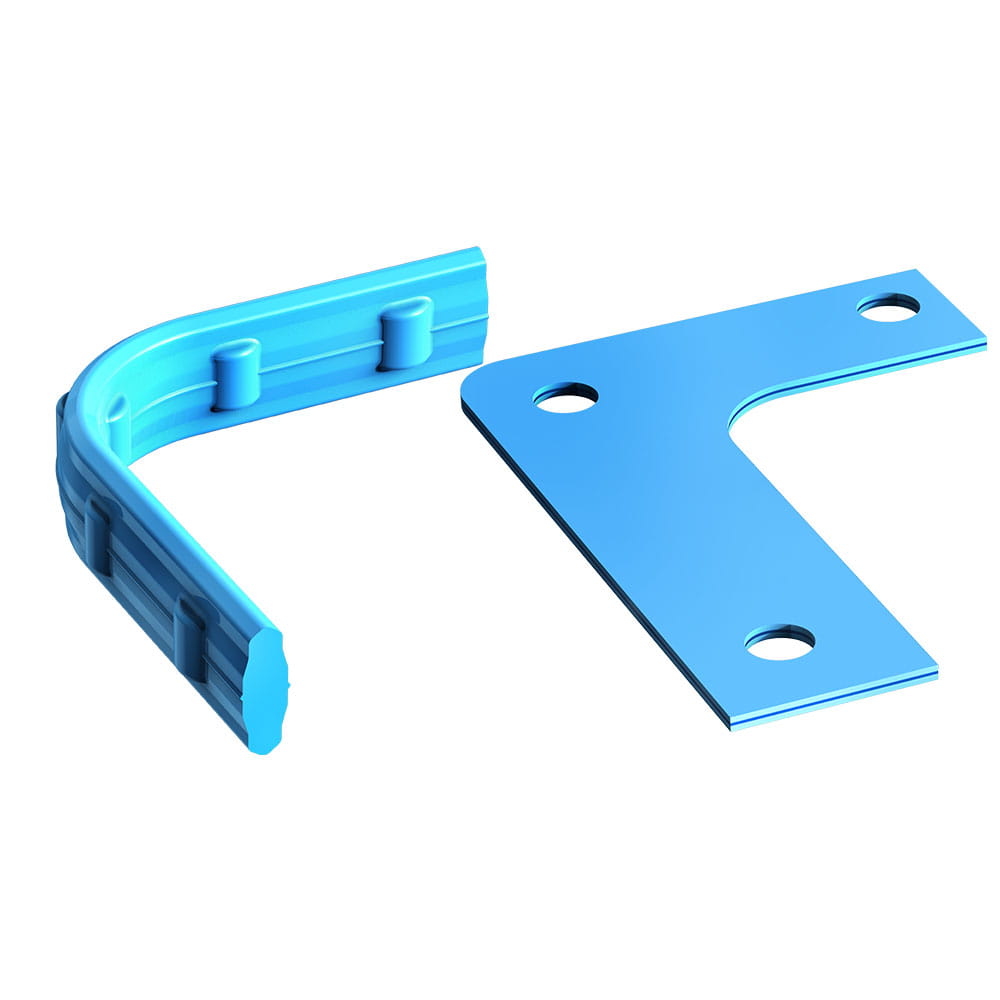

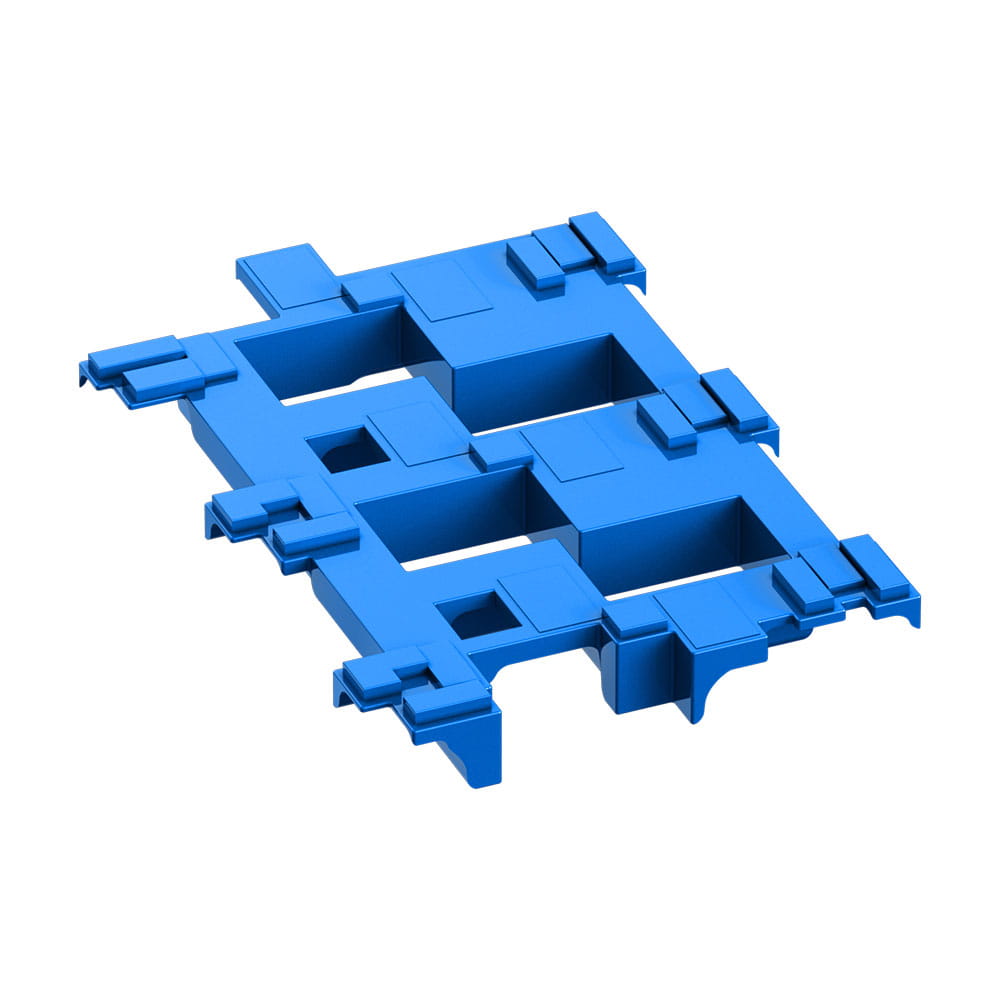

Gaskets

- Selection of gasket technologies and design features to meet application requirements

- Premium elastomers and design expertise combine for high performance sealing solutions

- Elastomers formulated to exceed lifetime sealing requirements

- Elastomers compatible with multiple fluid combinations in a wide range of temperatures and other challenging conditions

- Gaskets are designed for fast, efficient assembly and do not require special surface treatment

Tubes

- Effective fluid (1PIC) and gas transfer (2PIC) for cooling and various operations, highlighting our capability with both 1PIC and 2PIC technologies.

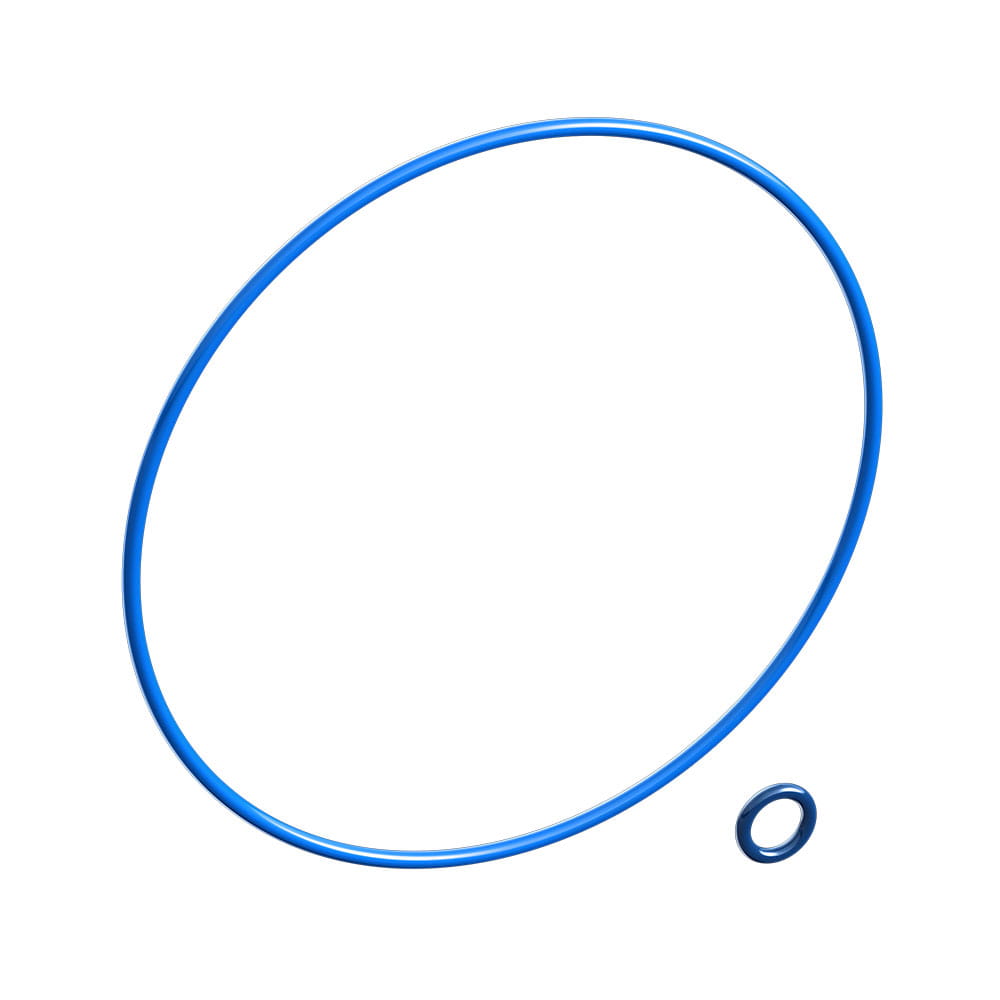

O-Rings

- Chemical resistance against most coolant types

- Excellent sealing capabilities for protection and longevity

- Low compression set for long term performance

- Easy installation and twist-safe seating designs

- Decreased wear to promote increased product lifetime

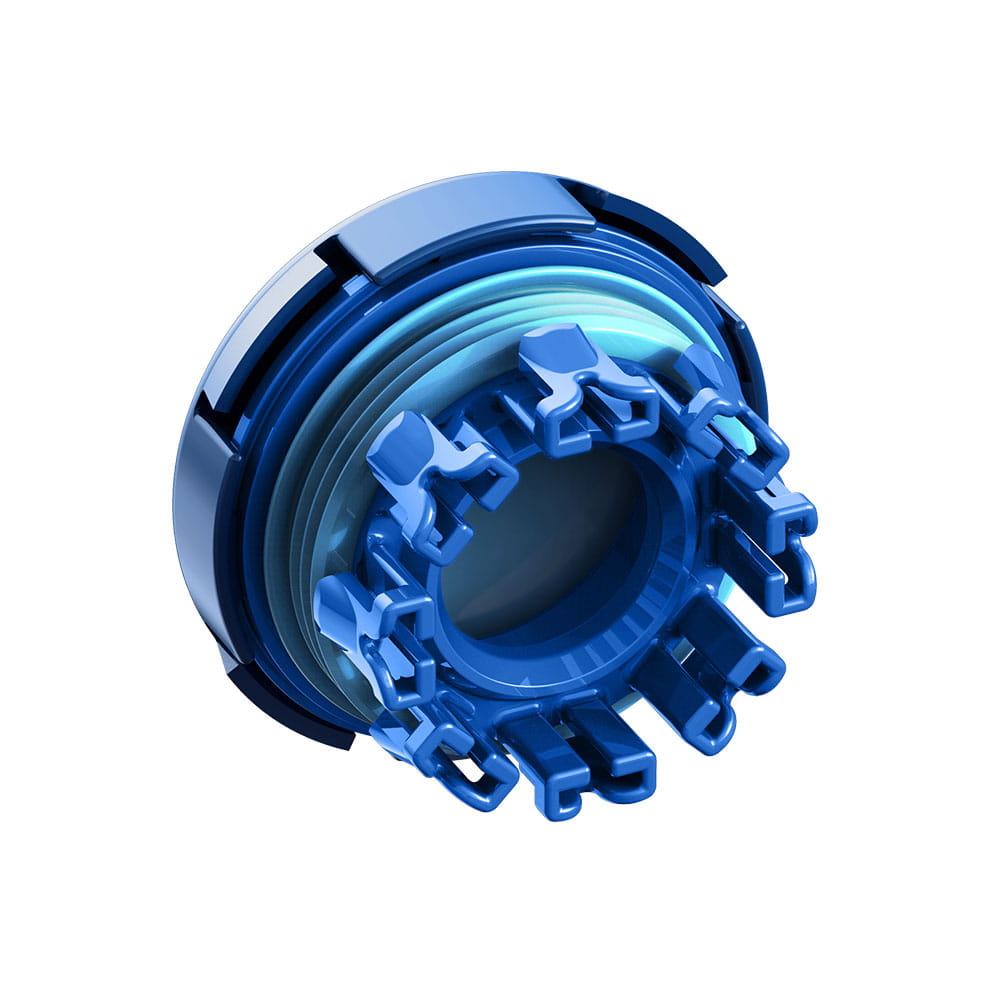

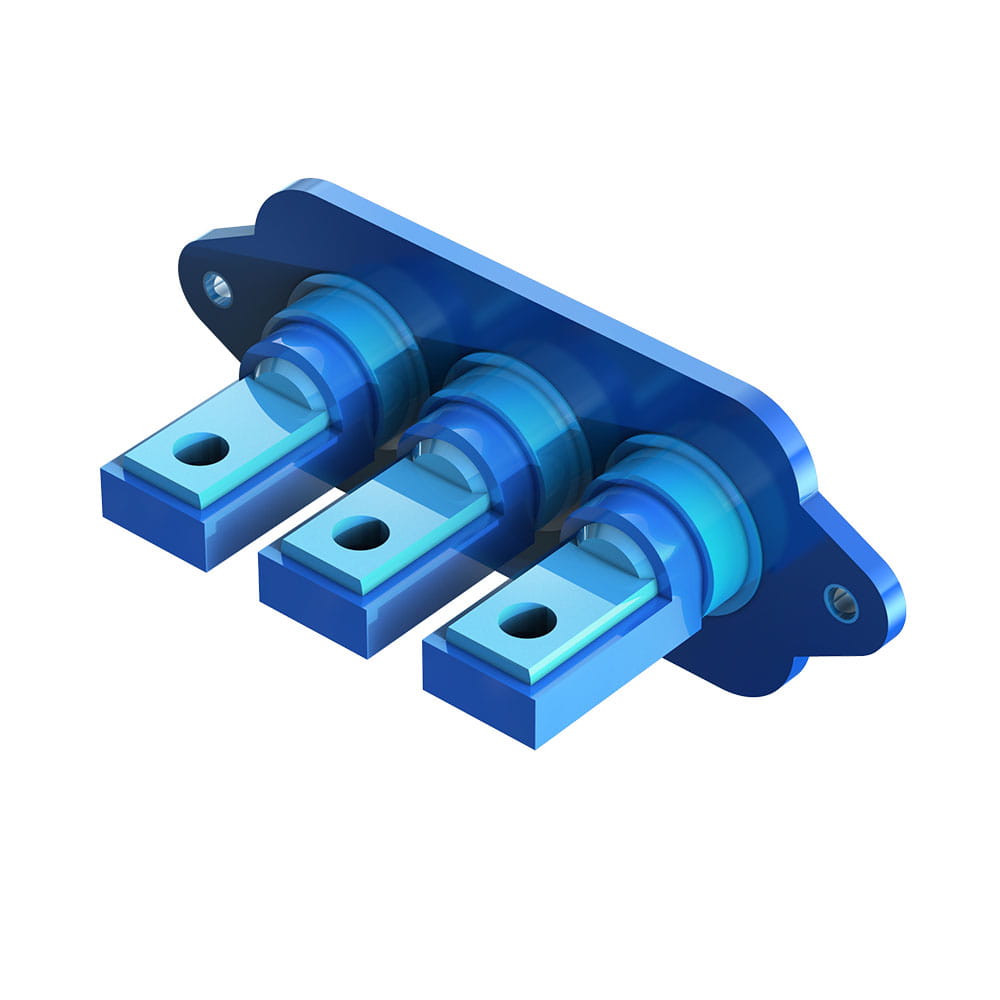

Dynamic Seals

- Superior performance in high-speed and high-pressure environments, with unmatched quality and reliability

- We have an extensive experience across diverse applications globally, covering a wide range of pumps for coolant distribution units

- With a variety of designs and rubber materials, we can accommodate numerous media, temperatures, pressures, and rotation speeds

- Options for pre-greasing are available as well

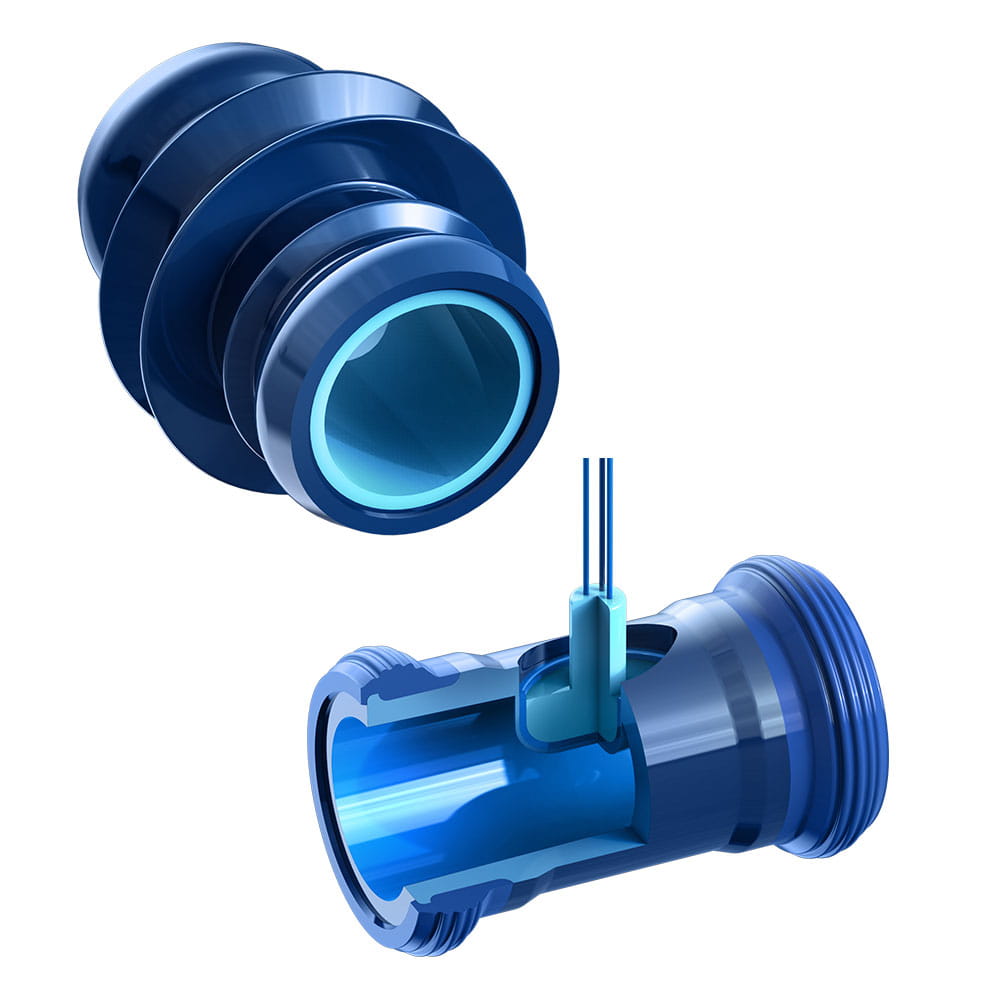

Plug & Seal

- Quick and reliable sealing for various applications

- Quick maintenance with a plug-and-play solution that minimizes downtime

- Capability to integrate different types of sensors

- Covers a broad spectrum of temperatures, media, and pressures

- P&S can accommodate assembly tolerances

- Piping is adaptable to changing needs

DIAvent®

- Pressure equalization and venting to prevent pressure build-up

Thermal Interface Materials

- Enhanced heat dissipation for optimal temperatures

- We offer tailored solutions for enhanced efficiency with the focus on direct heat distribution

- We are experts in both heat-conductive and heat-resistant materials

Feedthrough sealing

- Robust and proven design to prevent leakage

- Standard design for cost advantages, with a possibility of designing your own geometries for maximum efficiency and robustness

- Wide range of materials for fluid compatibility

- Wide temperature range possible (for both 1PIC and 2PIC systems)

Discover More on Our Sealing Solutions

News & Stories about Data Center Solutions

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new