Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Busbar Sealing

A better sealing solution to make busbars, pins and terminals media or gas tight.

Busbars, pins, and terminals are names for metal parts that act as pathways for electricity. In cases where fluids, gases, debris or pressure are present are present on one side, these busbars need to be sealed. Freudenberg Sealing Technologies offers a variety of sealing elements for these interfaces.

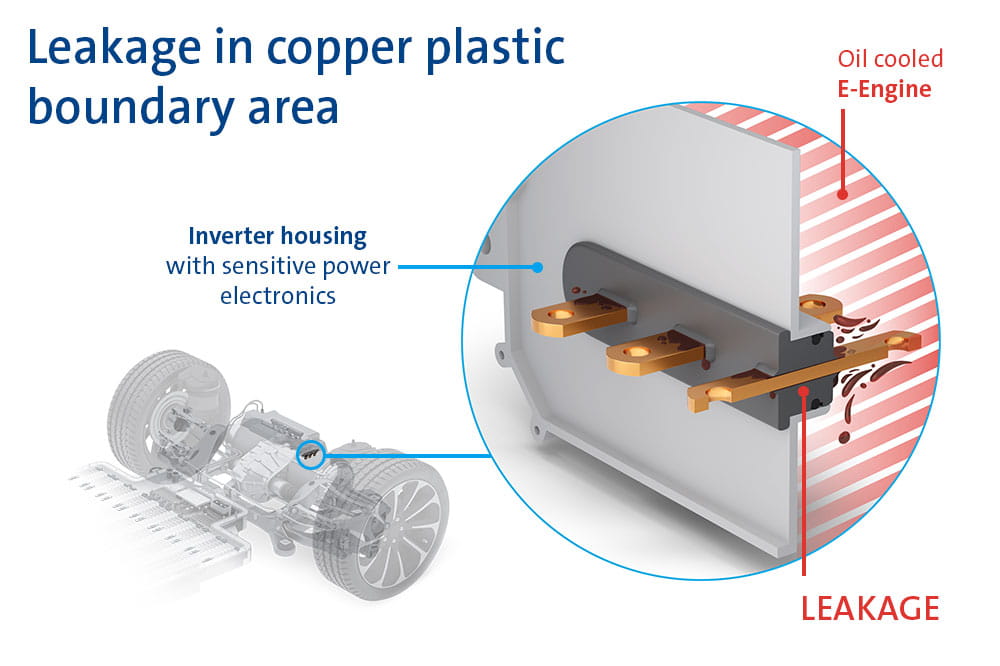

The need for media tight sealing between the high voltage busbars of an oil cooled electric motor and inverter as well as batteries are widely known. At the same time, media-tight busbars in low voltage applications like electric (oil or coolant) pumps, compressors or multi-pin connectors are showing an increasing importance.

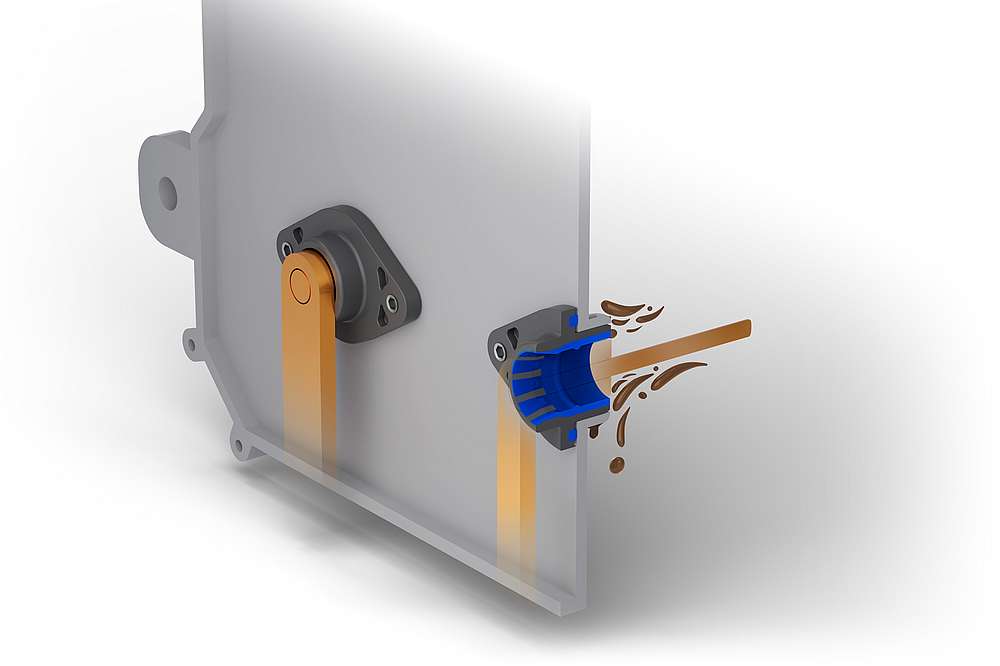

The majority of the market uses busbars stamped out of copper or aluminum sheets, which are then bent to the required dimensions. The rectangular conductor cross-section resulting from stamping is not ideal for sealing with standard seals since the corners of the cross-section do not allow robust compression of the sealing material.

Also, round busbars are in use and, depending on requirements and application, a cost-efficient and reliable sealing solution.

When it comes to busbar sealing, a media-tight interface is crucial to prevent oil or gas leakage as well as preventing pressure drops.

A Groundbreaking Solution from Freudenberg

As the leader in the sealing solutions market, Freudenberg Sealing Technologies is developing groundbreaking technology that provides a more sustainable, tight-seal solution because the current offerings within the market aren’t cutting it.

Download our solutions sheet to learn more about this innovative busbar sealing solution and why it’s better than current busbar sealing offerings in the market.

Benefits at a Glance:

-

Media tight rectangular and round bus bar interfaces

-

Total cost advantages for mass production

-

Less assembly effort through function integration

-

Media tightness under challenging operating conditions (e.g., in hybrid transmissions or e-axles)

-

Design freedom of busbar interface and complex geometries possible

-

Sealing for high voltage and low voltage applications