Flight Control Systems and Transmissions

Sealing solutions and materials for flight control systems and transmissions - Commercial aviation

Flight control systems and the associated gearboxes are crucial interfaces between the pilot's control commands and their mechanical implementation. They control all primary and secondary control surfaces such as ailerons, elevators or landing flaps and thus significantly influence the flight performance and safety of modern commercial aircraft. In this demanding environment, efficient sealing solutions make a decisive contribution to performance in commercial aviation. Freudenberg Sealing Technologies offers sealing solutions and high-performance materials that are precisely tailored to the special requirements of flight controls and gearboxes: They prevent leaks, ensure optimum performance and minimize maintenance requirements. In this way, they make an active contribution to the long-term reliability and cost-effectiveness of modern aircraft fleets.

Benefit from high-performance sealing technology - precisely tailored to your requirements in flight control and transmission technology.

Technical challenges for flight control and transmission seals

Precision meets resilience

The technical challenges for flight control systems and their seals are high. This is because they must enable precise control movements even under extreme hydraulic pressures and intense vibrations in order to ensure a safe flight attitude at all times. Accordingly, these systems require seals that can withstand both extreme hydraulic pressure and high dynamic loads over the long term. At the same time, the seals for gearboxes in or on the tail unit, which are responsible for transmitting the control commands, must be able to withstand enormous mechanical stresses and considerable temperature fluctuations - from icy cold at cruising altitude to extreme heat in the engine area.

All sealing requirements at a glance:

- Extreme hydraulic pressures and dynamic loads

- High temperature differences from -70 °C to +250 °C

- Resistance to aggressive fluids (e.g. Skydrol®, HyJet®)

- Reliable tightness against oil and fluid leaks

Maximum safety as the top priority for flight controls and gearboxes

The safety requirements for flight control systems and transmissions are extremely high, as their failure leads to loss of control of the aircraft. For this reason, for example, all hydraulic systems in the flight control system - like all other safety-relevant components and systems in commercial aircraft - are duplicated. This redundancy prevents single point of failure (SPoF), i.e. the failure of one critical component does not lead to the total failure of the entire system. All systems must enable high-precision control movements under extreme conditions in order to ensure a safe flight attitude at all times. The seals used in the flight control system are exposed to extreme hydraulic pressures and intense vibrations.

Less maintenance, more performance - seals with a system

In addition to the important safety aspects, commercial aviation also focuses on other important factors:

- Maintenance and reliability: minimizing maintenance intervals and maximizing service life

- Weight optimization: lightweight construction to increase fuel efficiency

- Efficiency and performance: optimal power transmission and minimal power loss

- High safety standards: fulfillment of strict technical compliance standards (e.g. AS9100)

Freudenberg Sealing Technologies offers specially developed sealing solutions and high-performance materials that are precisely tailored to the unique requirements of flight controls and transmissions. Our products reliably ensure absolute tightness and optimum performance, prevent leakage, reduce abrasion and minimize maintenance. In this way, we not only ensure maximum operational safety and efficiency, but also actively contribute to improving the long-term reliability and cost-effectiveness of modern commercial aircraft fleets.

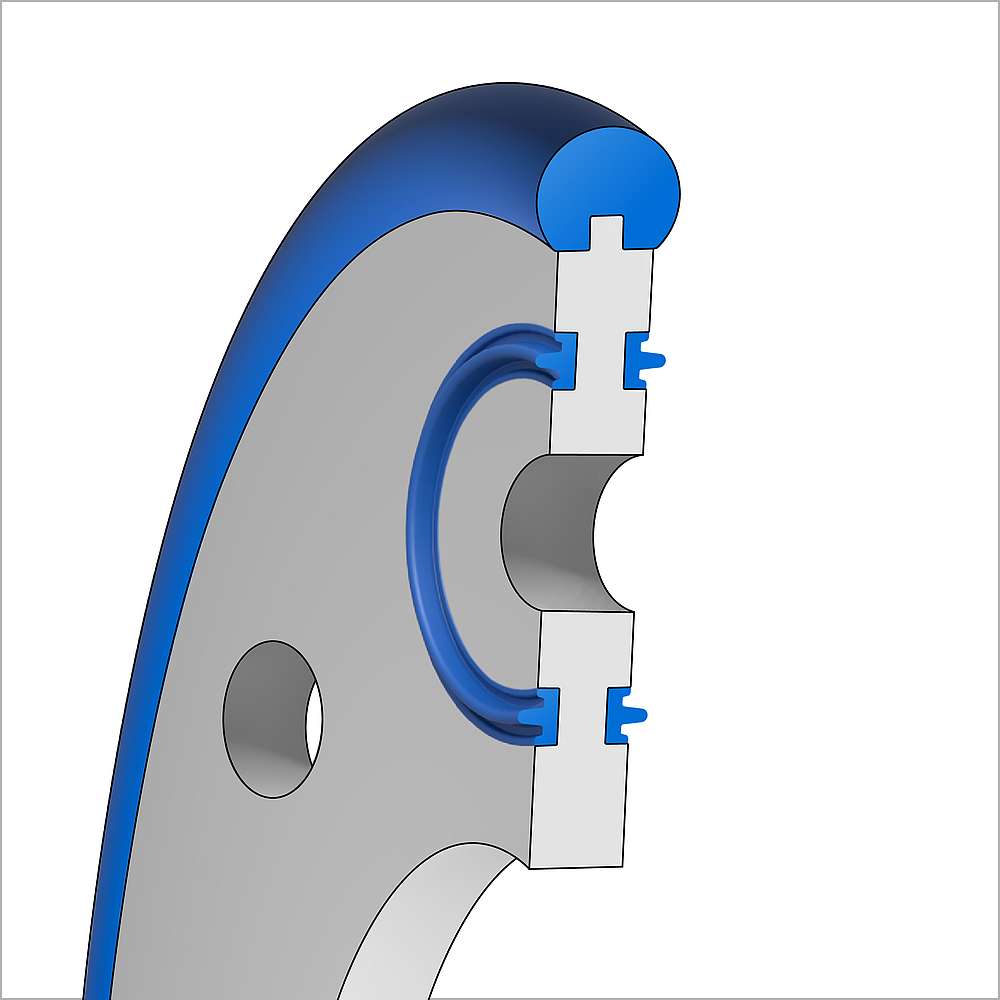

Sealing solutions for flight controls and gearboxes at a glance

Freudenberg Sealing Technologies offers a broad sealing portfolio that optimally meets the challenges in flight controls and transmissions:

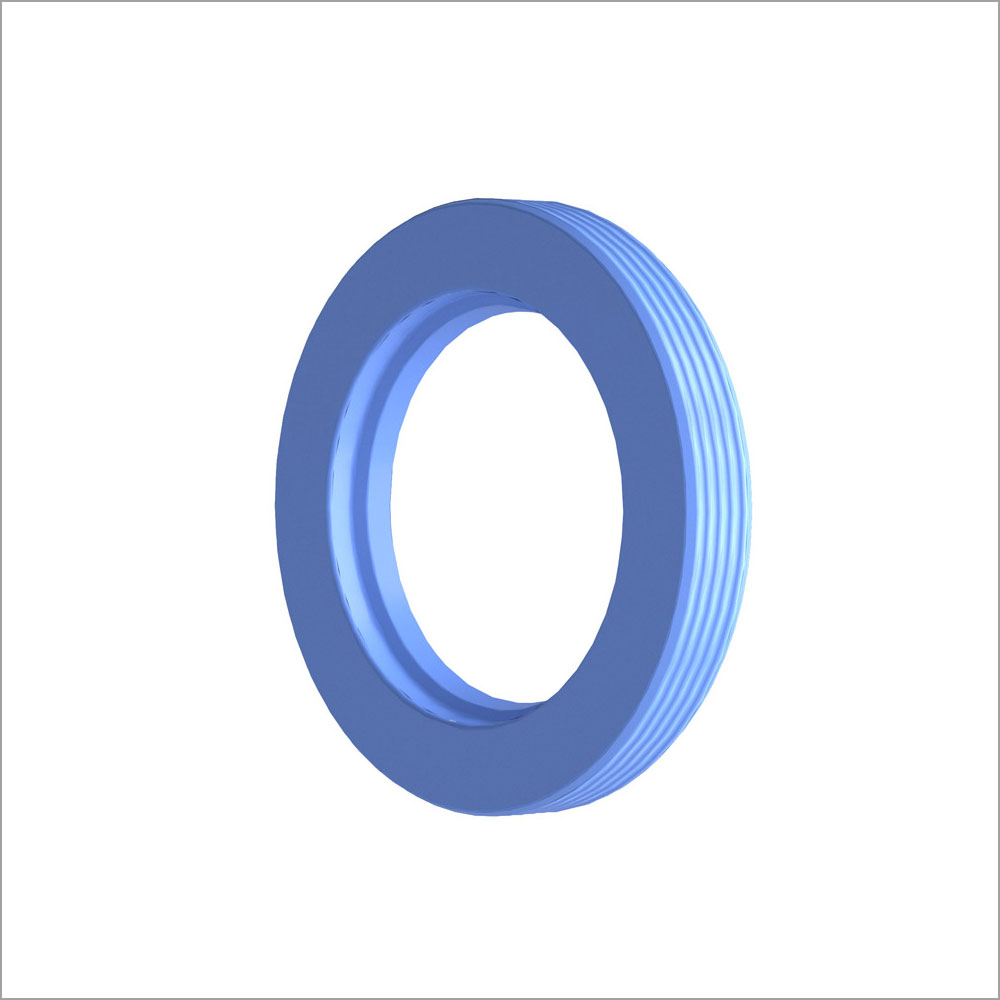

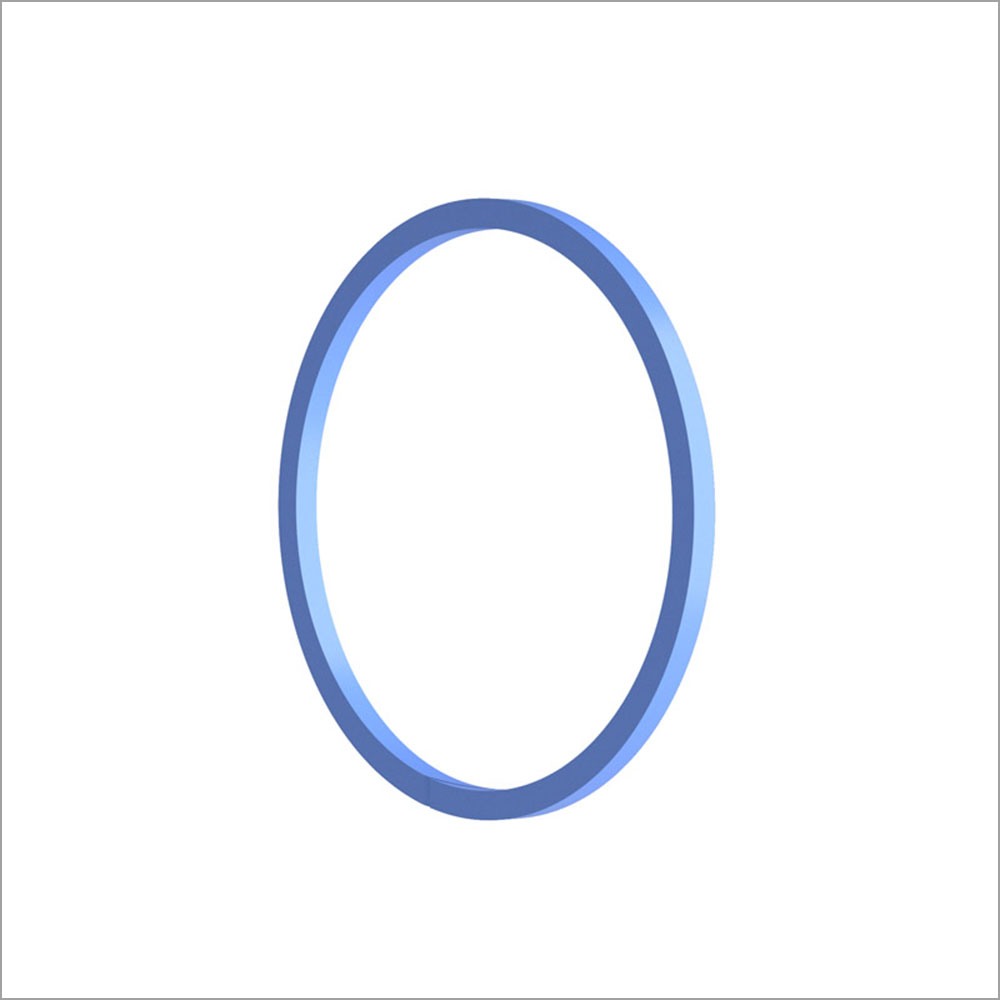

O-Rings

Universal seals, ideal for static and dynamic applications, particularly flexible and reliable under high pressure loads.

Back-up rings

Prevent the extrusion of O-rings under high pressures and increase their service life.

PTFE Seals

Outstanding thermal and mechanical resistance, particularly suitable for extreme temperature and pressure conditions.

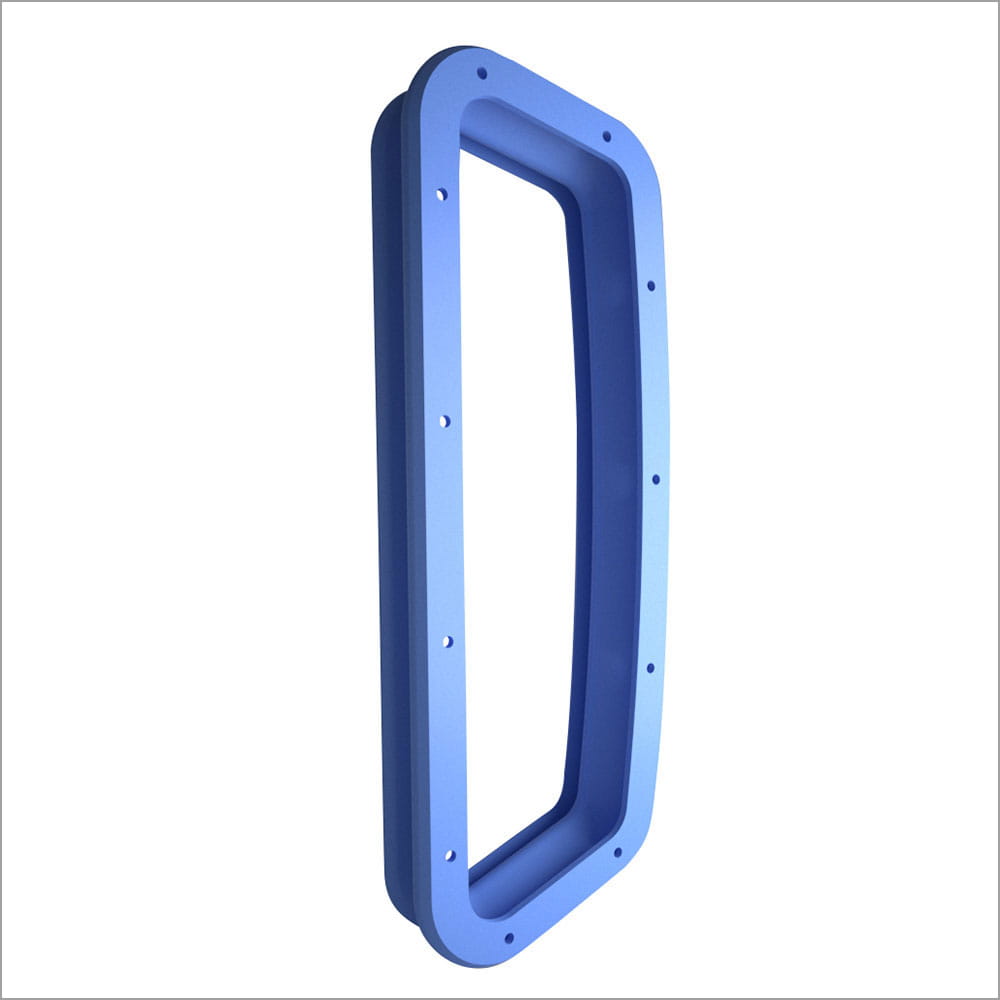

Plate Seals

Ideal for large-area seals, for example between housing halves, offer permanent tightness even under vibrations.

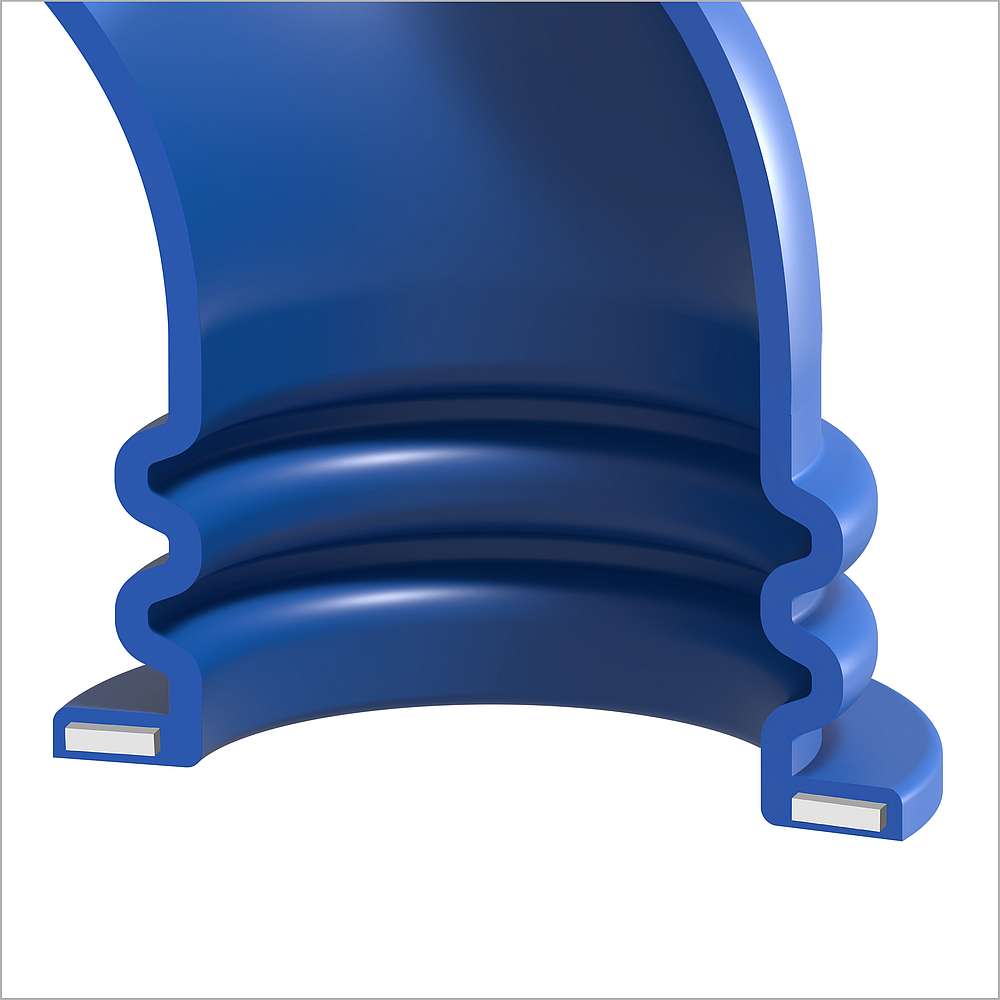

Rod Seals

Ensure the sealing of moving piston rods in hydraulic cylinders under dynamic loads.

Wipers

Protect hydraulic systems against the ingress of dirt, dust and moisture, increase the service life of sealing systems.

Piston Guides

Support precise piston movements, reduce friction and increase system efficiency.

Rod Guides

Enable precise guidance and stabilization of piston rods, reduce wear and extend service life.

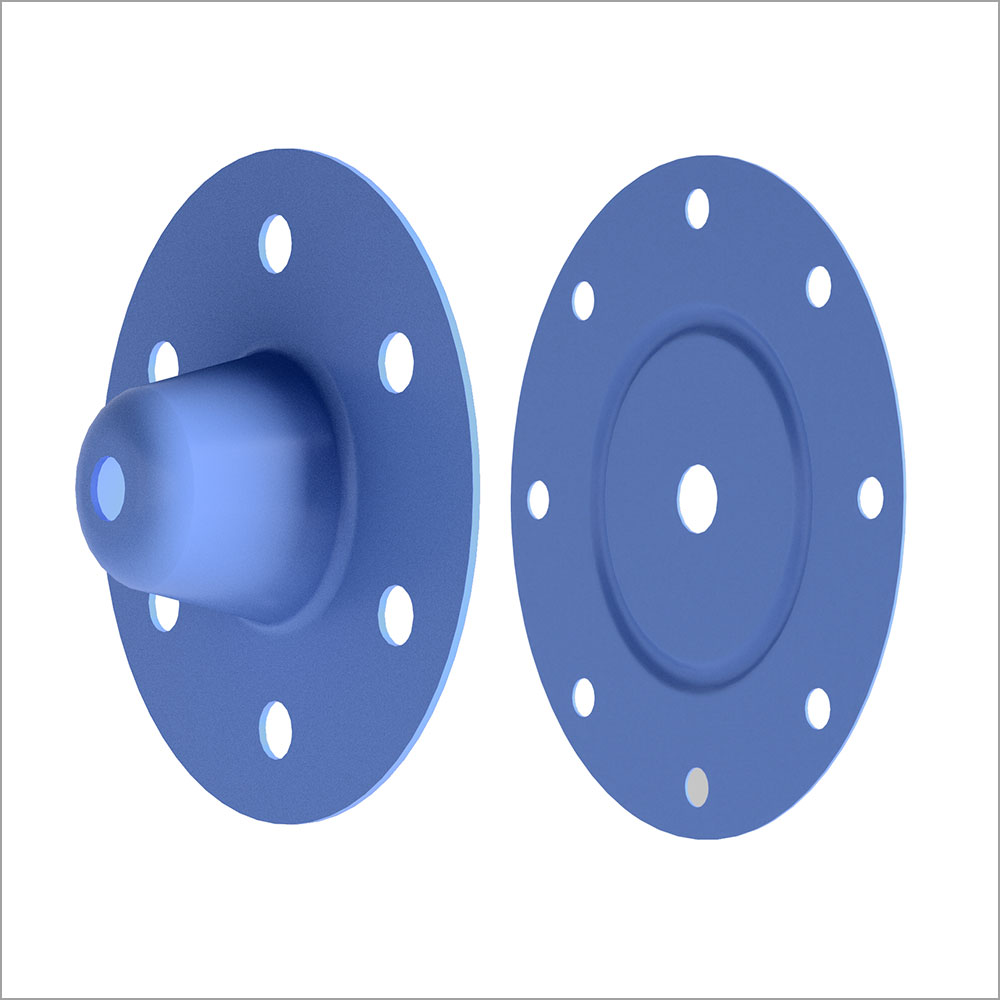

Diaphragms

Ensure reliable pressure separation, especially in sensitive valve systems.

Hydraulic seals

Specially developed for extremely high pressures and demanding conditions, offering reliable performance in hydraulic applications.

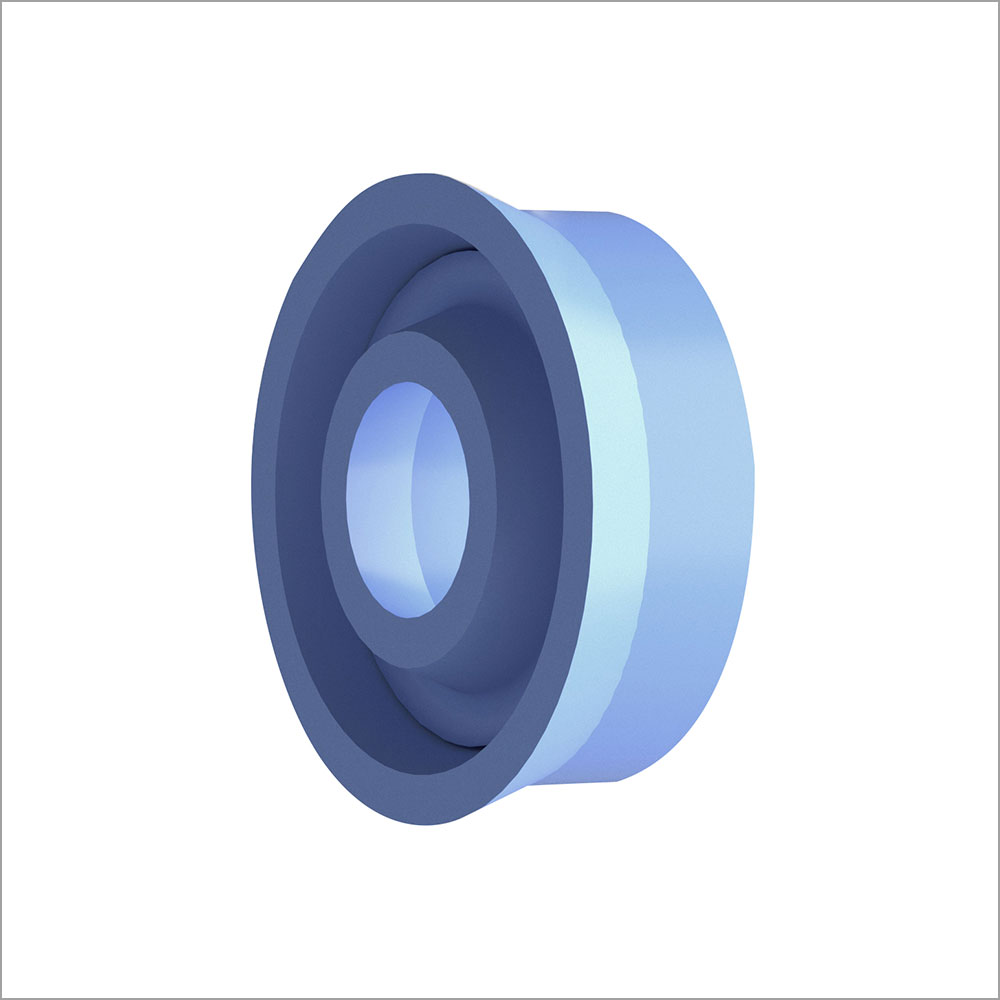

Rotary Seals

Provide effective protection against oil and fluid leaks in rotating components.

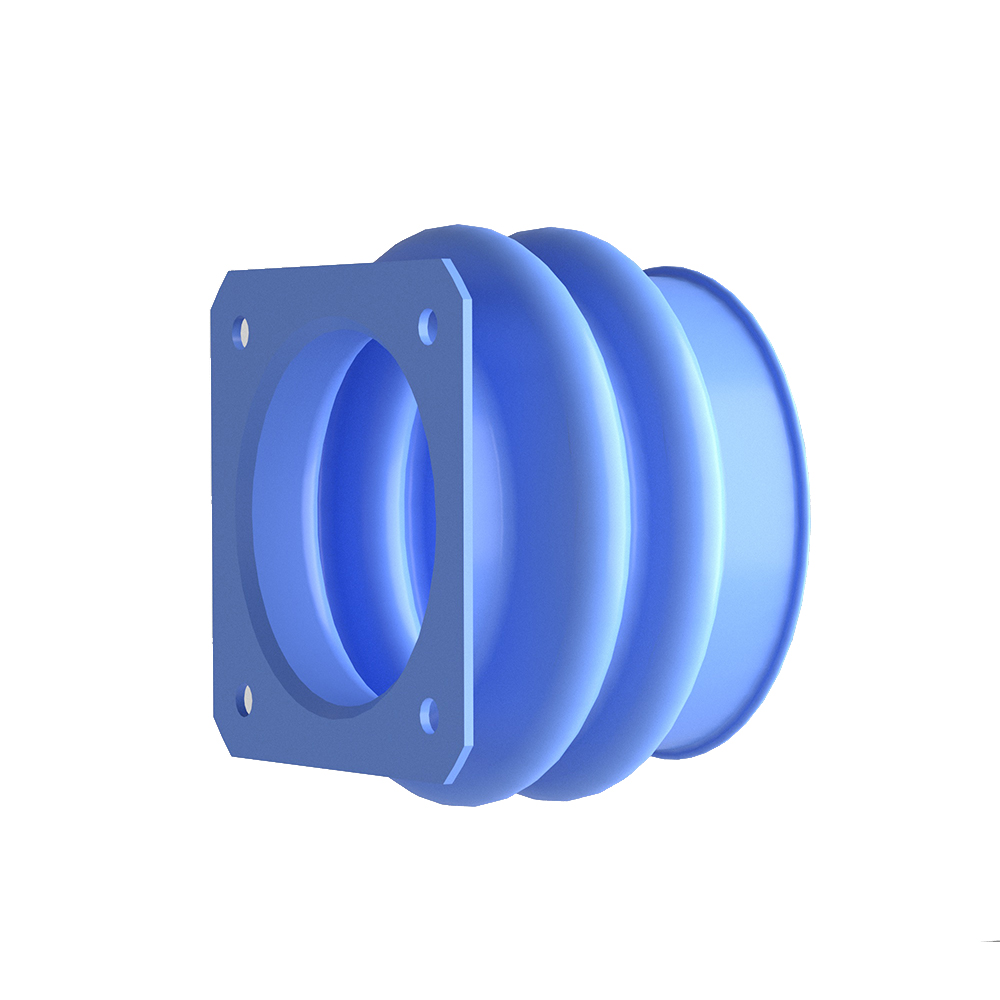

Elastomer Ducts

Flexible line guides for air and fluid systems reduce mechanical stress and improve system flexibility.

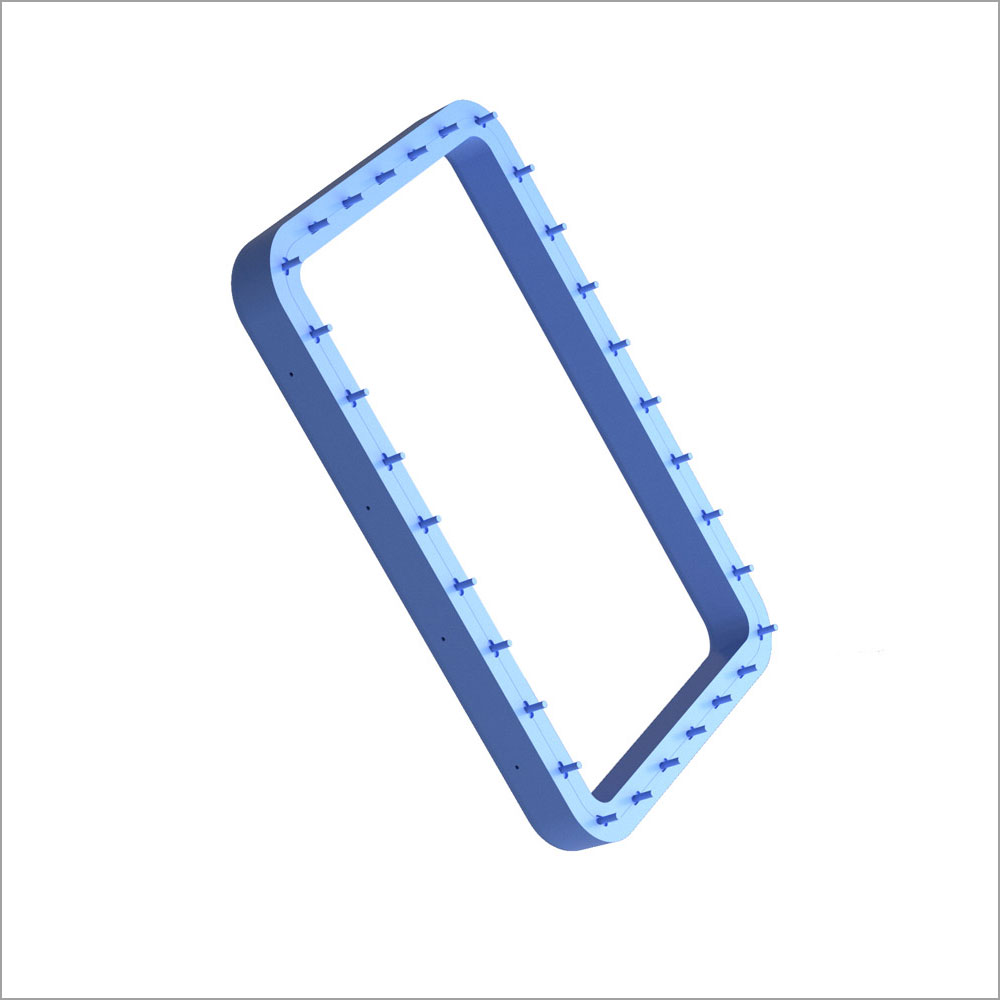

Plenum Seals

Highly effective seals for air distribution systems improve system efficiency and minimize energy loss.

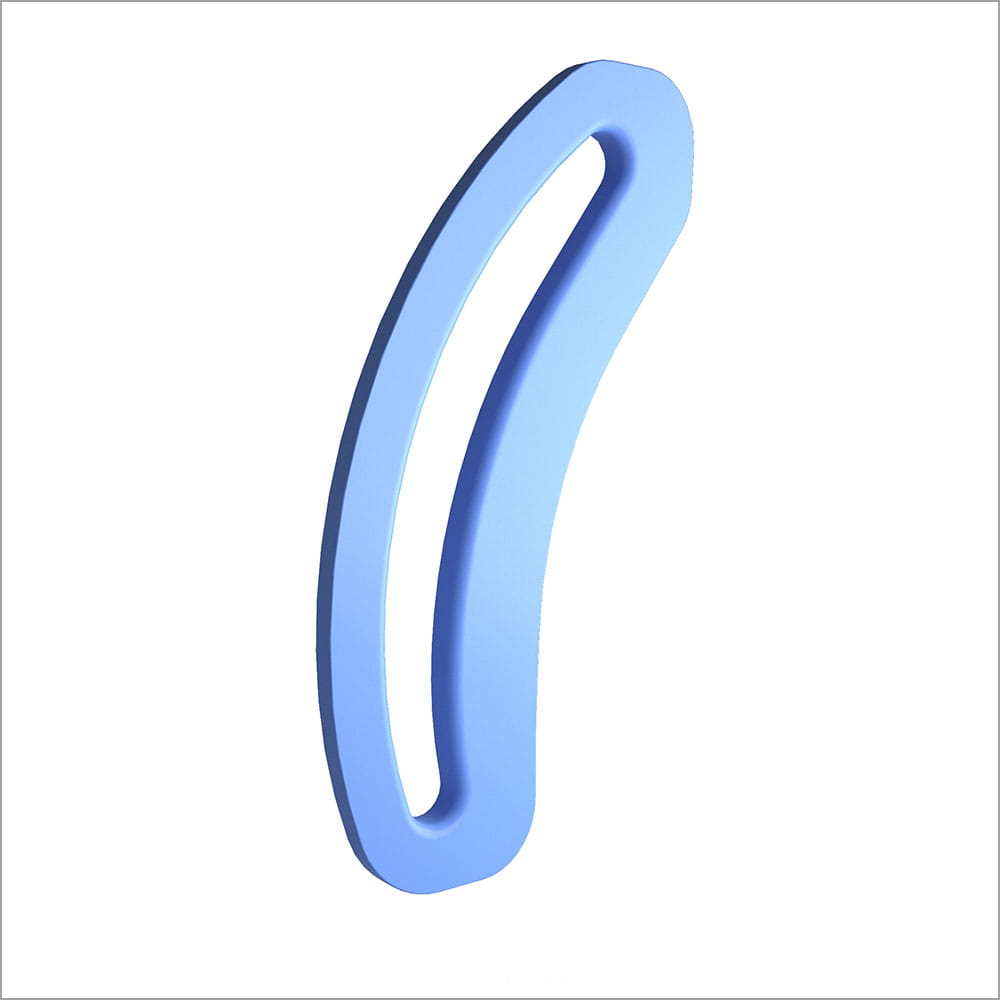

Kiss-Seals

Precision seals with minimal friction losses, ideal for highly sensitive applications.

Grommets

Provide protection and reliable sealing of cable and pipe penetrations.

Protection for fuel lines

Effective protection against mechanical damage and leaks.

Protection for electrical connections

Against environmental influences such as moisture and dust.

High-performance materials for commercial aviation

For the specific requirements of commercial aviation, Freudenberg Sealing Technologies focuses on high-performance materials - tailored to the respective application:

EPDM (ethylene propylene diene rubber):

- Excellent resistance to hydraulic fluids such as Skydrol®.

- Very good weather and ozone resistance.

- Optimum performance at low temperatures.

NBR (acrylonitrile butadiene rubber):

- Good oil and fuel resistance.

- Universally applicable in dynamic and static applications.

FKM (fluororubber/viton):

- Excellent temperature and oil resistance.

- High chemical resistance to aggressive media.

- Ideally suited for gearbox applications and high temperature ranges.

FFKM/SIMRIZ® (perfluoroelastomer):

- Highest chemical and thermal resistance

- Excellent for extremely demanding applications, especially with aggressive chemicals.

PEEK (polyetheretherketone):

- Outstanding mechanical strength and temperature resistance.

- Ideal for demanding mechanical applications in gearboxes.

- Low weight with high strength.

PTFE (polytetrafluoroethylene):

- Very low friction, excellent chemical and thermal stability

- Universally applicable in sealing solutions with high demands on resistance and friction properties.

Quantix®:

- Special material developed for the highest performance requirements.

- Excellent combination of mechanical stability, chemical resistance and service life.

FVMQ (fluorosilicone):

- Outstanding resistance to fuels and oils.

- Stable at extremely low and high temperatures.

- Ideal for seals that are exposed to temperature fluctuations and aggressive media.

VMQ (silicone):

- High flexibility and elasticity over a very wide temperature range.

- Excellent for applications that require good temperature resistance and sealing performance at low pressures.

Flight control - precision for every flight movement

Flight controls are all the systems and control surfaces that pilots use to control the attitude and direction of a commercial aircraft. These systems are the "heart" of aviation, as they convert the pilot's commands into movements of the control surfaces and thus enable safe and precise navigation of the aircraft. This includes both the controls in the cockpit (control horn/sidestick, pedals, etc.) and the connecting mechanisms and actuators that ultimately move the control surfaces. Without advanced flight control systems, modern commercial aircraft would not be able to fly stably and safely.

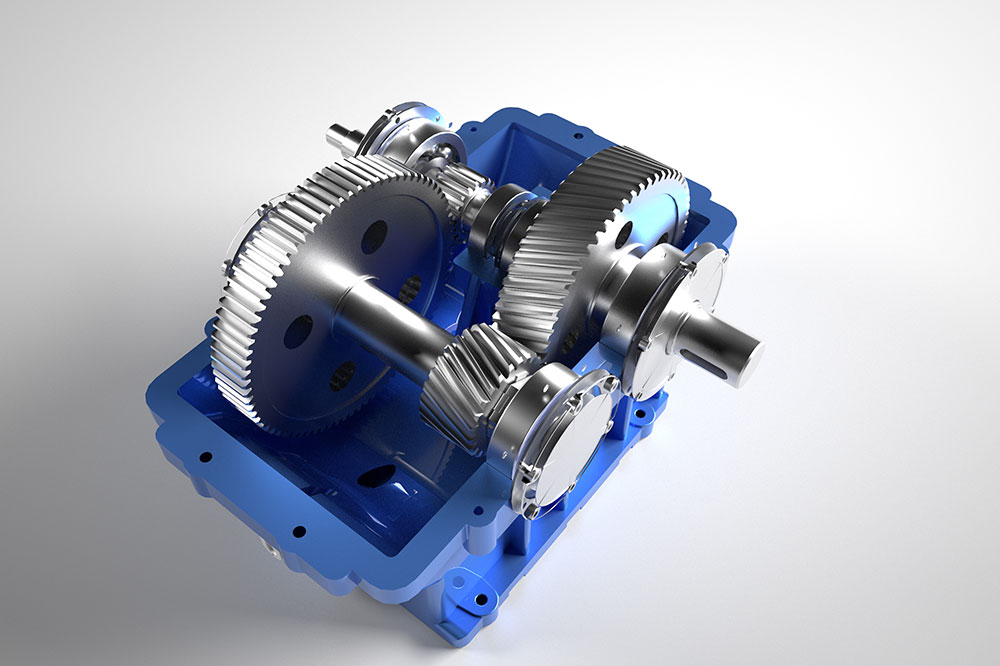

Gearboxes for flight controls: A central component of modern aviation

Gearboxes are important components for power transmission and adaptation of mechanical movements in flight control systems. They adapt the mechanical movements coming from the actuators in terms of speed, torque and exact position, thus enabling precise control of the aircraft control surfaces.

Freudenberg Sealing Technologies offers various high-performance sealing solutions depending on the specific requirements for each type of gearbox:

Certifications and compliance - our quality promise

Freudenberg Sealing Technologies is a leading partner to the global aviation industry. With high-quality sealing solutions and innovative high-performance materials, we not only meet today's requirements of the aviation industry, but also those of the future - from maximum reliability and service life to consistent lightweight construction and sustainable material selection. We comply with all relevant international aviation standards - and go above and beyond in many areas. Our customers benefit from uncompromising quality, clearly documented processes and verified traceability. This strict adherence to certifications and compliance standards ensures maximum safety and reliability. The approval and use of our products by renowned OEMs and system manufacturers worldwide confirms the reliability of our solutions.

Our certifications at a glance:

- AS9100D: Quality system specifically for the aerospace industry

- ISO 9001: Standardized quality management

- NADCAP: Accreditation for critical special processes in aviation

These standards guarantee the highest quality and maximum safety in every project phase.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new