Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

19.07.2022 | Story

The Glue of Civilization

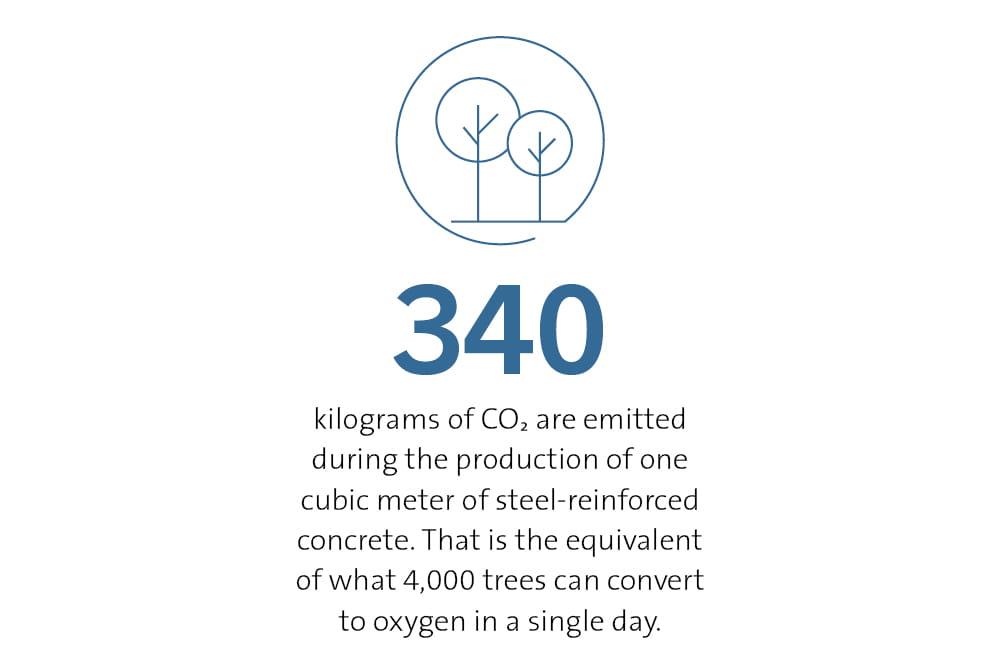

Cement ensures that the ingredients of concrete adhere to one another. And the global demand for concrete continues to grow. But that creates an emissions problem in many respects. The construction industry is facing a challenge if it wants to make its operations carbon-neutral.

Terms like “energy” or “transportation” are easy to find on lists of industrial sectors that produce high amounts of CO2 emissions. But the terms “building” and “housing” are less common, although these sectors account for a whopping 38 percent of global CO2 emissions. In many reports, they crop up in a range of different sectors. Buildings are assigned to the energy sector, along with heating, electricity and gas – and building materials in turn fall under the category of “industrial processes.”

Construction materials, in particular, are significant. About 2.8 gigatons of carbon dioxide are produced in the cement industry. This amount is partially driven by the extremely high temperatures used to produce cement. This involves burning limestone at 1,450°C (2,642°F) to create “clinker.” The process is energy intensive and mainly relies on fossil fuels, even if the industry is now increasingly burning waste, sewage sludge or waste oil. At least 30 percent of the required energy still comes from brown or black coal. Still, the energy expenditure is responsible for just one-third of the CO2 emissions.

Emissions From Burning Lime

Here’s a much greater problem: When crude lime is transformed into potassium oxide, limestone is de-acidified. That releases enormous quantities of bound CO2. While it is at least conceivable to draw on green energy for the energy input, this chemical process cannot be changed – the raw material itself is the problem. You would have to find a substitute for either the lime or the cement that comes from it.

The cement ensures that the components, including sand, water and gravel, coalesce into concrete. It is the glue of civilization today. Factories are built with concrete, as are warehouses, bridges, dams, roads as well as many residences and office buildings. Concrete offers benefits: It is extremely pressure-resistant, and it effectively protects steel from moisture and corrosion. It is estimated that about 6 billion tons of cement are produced annually, and the amount is rising. Continuing urbanization is leading to another construction boom that could extend far into the future. In just two years, more concrete was produced in China than in the United States over its entire history. And the construction industry is sticking with concrete. It is a proven, known material that is very affordable.

Textile and Carbon Concrete

Alternatives exist but have yet to generate widespread interest or commitment. The first possibility is to replace the lime, perhaps with volcanic ash or so-called Belterra clay, the layer of clay that covers bauxite deposits. It has to be removed from the bauxite anyway during extraction. Researchers have used it to develop a cement where the clay replaces at least half of the lime. One positive side effect: At 1,250°C (2,282°F), the firing temperature of the clay is lower than the firing temperature of limestone. This could reduce CO2 emissions by nearly 60 percent, overall. Other alternatives include textile-and-carbon concrete. They are composite materials made of fine concrete, carbon, glass or basalt. Since carbon fibers replace steel in this approach, less concrete is needed. The materials have been in use since 2005, though they are complicated to produce and process, and thus many times more expensive. They also raise issues for recycling, since it is hard to separate the carbon fibers from the concrete.

So if it is hard to replace lime, is less cement an option? Concrete for lightweight structures, so-called “gradient concrete,” could reduce material and energy costs by about 30 percent. This involves incorporating porous hollow spaces in the concrete where it is less stressed. But more research is still needed before lightweight concrete can be used widely and safely. And then regulators and experts will have to enact laws and standards to certify its safety.

Recycling Doesn’t Solve the Emissions Problem

Completely replacing concrete with wood also creates significant challenges. Wood has been such a hot commodity lately that prices for it have risen noticeably, and the already expensive material has been in shorter supply. To replace just one quarter of the concrete used each year, you would have to plant forests covering the equivalent of India. So wood is not a viable option for the foreseeable future.

Another possibility: recycling. This is important at least from the standpoint of resource efficiency. Recycled concrete does not need to be created all over again. But researchers are skeptical about its contribution to climate protection. To recycle concrete, it has to be crushed and ground – and even this takes energy. And, in the bargain, even recycled concrete requires new cement as a bonding agent, exactly the material responsible for substantial emissions in the first place. Still, there is another benefit of recycled concrete: It is possible to set up a resource cycle limited to a local area. This would especially have an impact on transport distances and the emissions tied to them. Transporting concrete requires heavy-duty vehicles, making the practice energy-intensive. The vehicles would also be hard to electrify.

Separation as an Innovation?

The construction industry would ideally like to adopt CO2 separation. Several million tons of CO2 can be eliminated with so-called CCUS (Carbon Capture Usage and Storage), according to estimates. This involves separating out the carbon dioxide that is produced and transporting it over pipelines to storage sites. It could also be transformed into synthetic fuels. Researchers have worked on the innovation for more than a decade, and the first pilot projects have emerged. But it is still unclear whether the infrastructure required for CO2 transport can even be financed.

So there are some solutions, and the cement industry has expressed support for them for a long time, especially in industrialized countries. At the same time, concrete continues to be affordable – too affordable. There is little public push for the adoption of construction alternatives, especially in the fast growing urban centers throughout the world. But one thing is clear: If we don’t leave the glue of our building methods behind, it will be almost impossible to reach our climate goals.

More news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new