Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

04.05.2020 | Story

“There Is a Time for Every Invention”

How do we deal with change? Two Freudenberg Sealing Technologies managers, Claudio Zoppi (Vice President in Pinerolo, Italy) and Melanie Schneider (Vice President Sales in Weinheim, Germany) talk about disruption, innovation and the future of alternative powertrains.

Ms. Schneider, Mr. Zoppi, let’s talk about change.

How has your normal work routine changed since the start of your career?

Zoppi: There were no computers back then. That’s the obvious change. But I find it much more exciting to look at the way people used to work and how it has changed: the speed of our communications. The frequency of discussions, email messages, and the exchange of information. What once took a week now takes a day.

Schneider: I’ve now worked at Freudenberg Sealing Technologies for twenty years, and everything has become faster and more complex over this period. Today, all employees really work globally. They have to keep an eye on time zones and their intercultural projects.

Does this change your leadership style?

Schneider: Certainly. The approach used to be “command and control.” Today, there is much more information. To some extent, each of us has become a sensor in a complex world. And it has become important for managers to pick up even the faintest signals.

Zoppi: That is a nice image. I’ve also had to expand the range and adjust the orientation of my antennae. Gearing them to other cultures, for example. Sometimes certain details mean absolutely nothing to you. In other countries, they mean a great deal. I am sure that I’ve rushed through discussions too quickly at times.

Schneider: And that is a major challenge. Moving more slowly so you are ultimately faster.

Zoppi: Yes. If you proceed more carefully, you’re more likely to reach your goal.

You have to make mistakes if you’re going to learn.

Claudio Zoppi, Vice President Freudenberg Sealing Technologies, Werk Pinerolo (Italy)

Why do people often find change so difficult?

Zoppi: It’s always unpleasant to leave your comfort zone. It’s only human to want to stay in a safe, protected area. As a company, we have to create spaces where people feel safe. Employees who worry that their supervisors will criticize them will never leave their comfort zone. But then they don’t grow, they don’t develop, and they will never be innovative.

Nobody likes to make mistakes.

Zoppi: But you have to make mistakes if you’re going to learn.

Schneider: Even scientific progress works that way. Testing is used to determine what doesn’t work, in order to show what is possible. If you don’t get rolling, you aren’t going to reach your destination. Incidentally, that is a strong argument for diversity: The more diverse the participants are, the greater the diversity of ideas.

Zoppi: Any change is costly. But we always come out ahead in the process.

Schneider: Good point. We certainly give something up, but we get something in return.

Zoppi: Letting go is always difficult. This comes back to changes in management. Many managers have had a hard time giving up power, and that’s still the case, especially if they fail to understand how many new options they gain in the end.

But wouldn’t it make much more sense rationally for companies to continue to do what they do best?

Zoppi: If animals keep going to the same waterhole, and it dries up, they die of thirst. You have to look for other water sources ahead of time. It is really dangerous for us to be in our comfort zone long-term.

Schneider: The path to innovation can be tough going. It takes someone who will encourage staff. That is another reason why agile work is so popular today: achievable milestones, one after another.

Zoppi: And staff should be recognized as well. If everything goes well, employees and supervisors often believe the work was just a job that had to be done. No, the supervisor should congratulate the employees at the point where there is something to celebrate.

Schneider: Many people are their own biggest critics. What good does it do if I, the supervisor, add to the criticism? It is much better to encourage employees if they have reflected on their work themselves.

It's a paradigm change. People are buying mobility, not cars.

Melanie Schneider, Vice President Sales, Freudenberg Sealing Technologies

How would you describe the current state of alternative powertrains?

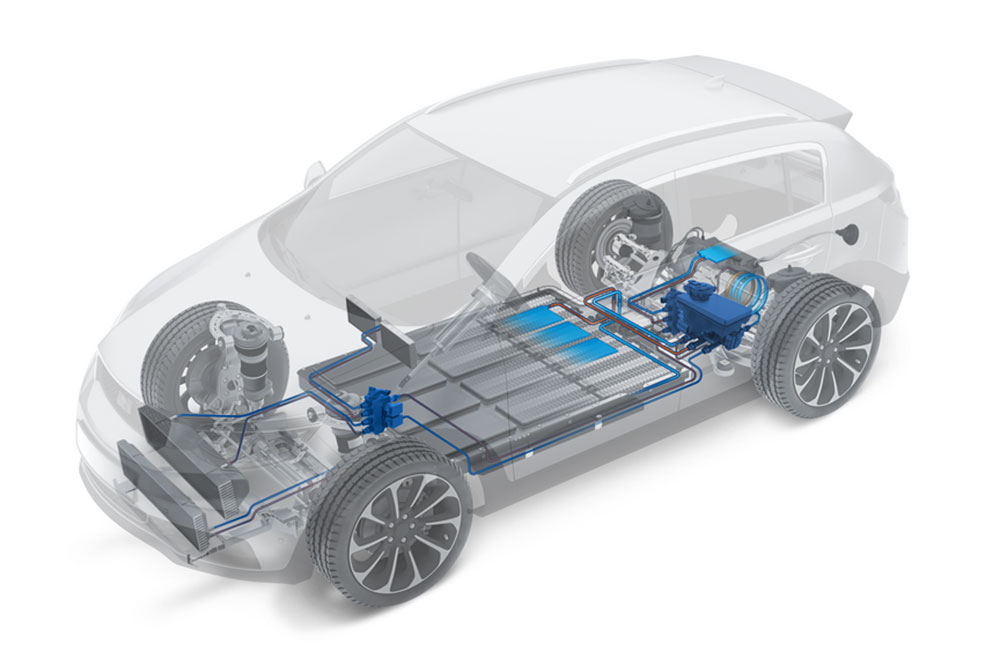

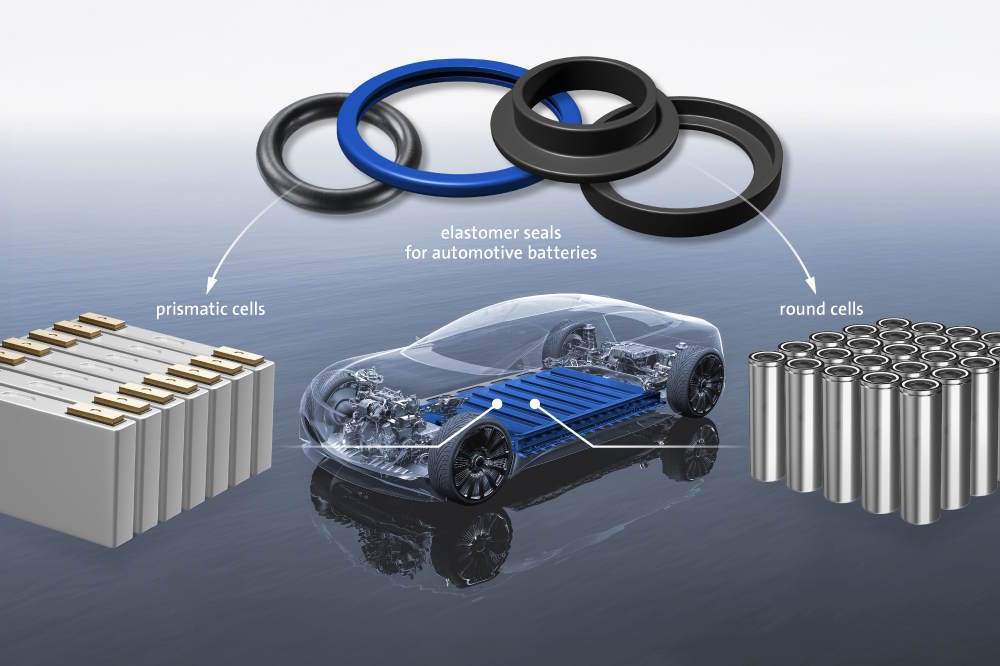

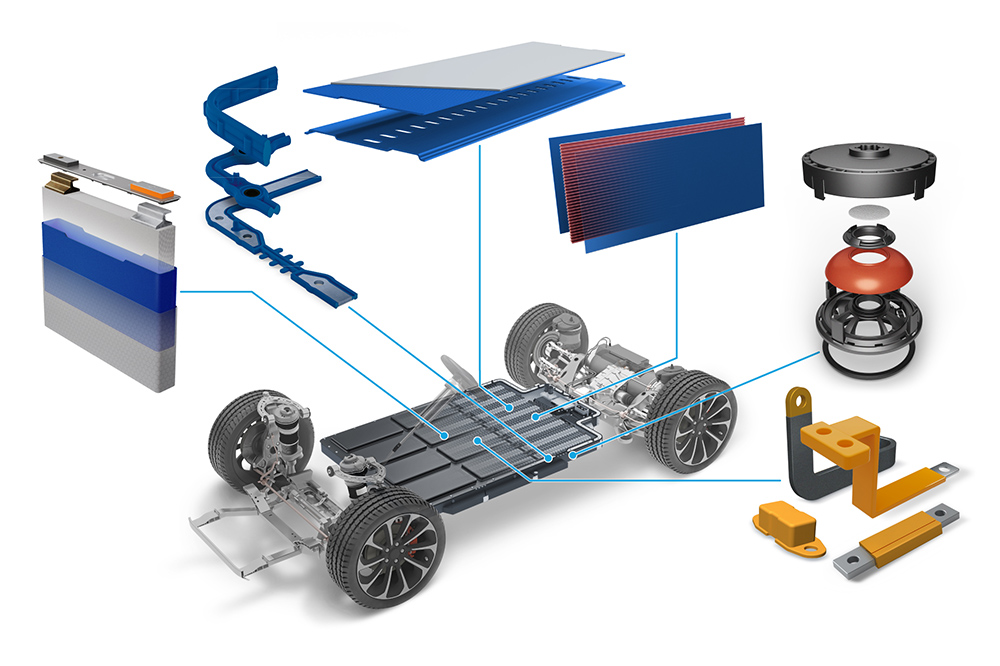

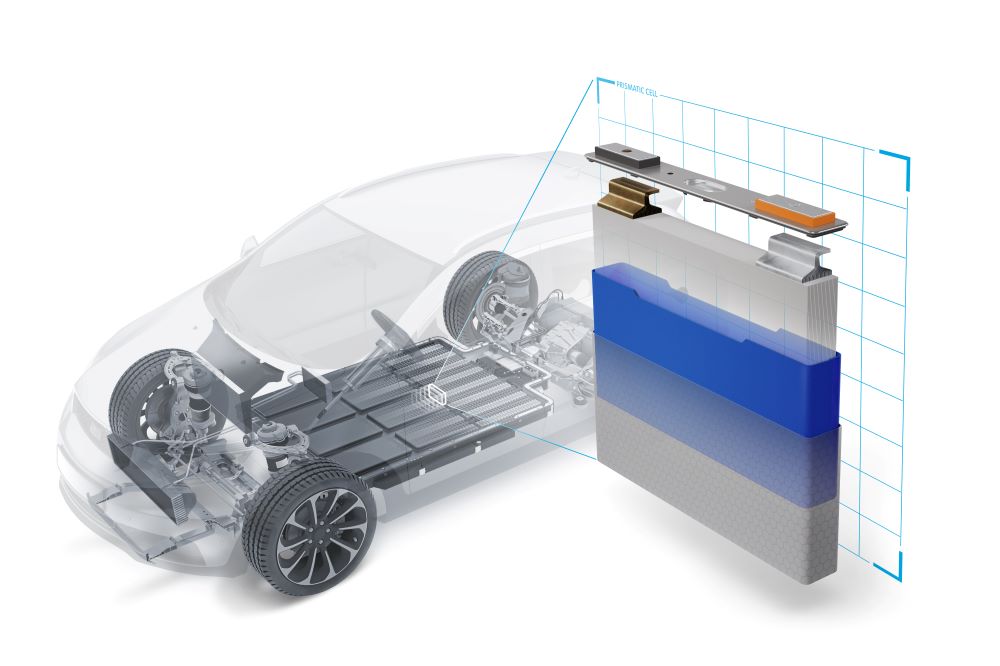

Schneider: The market has been completely and violently shaken. I am really curious as to what the next couple years will bring. Everyone used to have their own car. In the future, people may turn to car-sharing. There’s so much going on in the field. You can sense it at Freudenberg Sealing Technologies, where we have taken a major step forward by acquiring the battery manufacturer XALT Energy and the fuel cell company Elcore.

Zoppi: It all reminds me of the first iPhone. My son had one. At the time, I was convinced that I would never use it. And, of course, I have a smartphone today. Even the people who’ve been saying that they don’t want an electric car will end up owning one.

Schneider: I grew up out in the countryside, and my driver’s license was the ticket to freedom. But I don’t believe this will still be the case for the next generation. A lot is going to happen in the next five to ten years.

Zoppi: Consider all the questions regarding infrastructure and range that we wonder about today – how do we know whether the coming generation will use cars exactly the way we’ve always used them.

Schneider: It’s a paradigm change. People are buying mobility, not cars.

Zoppi: We do things with our smartphones that we hadn’t even thought of a few years ago. That’s why development timeframes are getting shorter and shorter. No one can afford to develop something over a period of years, only to see the requirements change long before it is finally finished. Think about the fuel cell. As a propulsion system, it has the potential to completely change the design of a car.

You say that we are on the brink of a breakthrough in electric motors. But the electric motor is more than 100 years old. Breakthroughs have been announced a number of times. Yet we still don’t have them.

Zoppi: There is a time for every invention. Artificial intelligence has been around for a long time. But there was no opportunity to use it. It is only now that we have the computing power for neuronal networks, along with the cloud and Big Data. The situation with electric powertrains is similar.

Have automakers figured out that they have to change?

Schneider: I think they have. Of course, they can keep doing what they already do best. We at Freudenberg Sealing Technologies will continue to bet on our strengths as well. But we are looking ahead.

Zoppi: A company can prepare for transitions. There is no disadvantage in at least thinking through the changes. There may still be automotive executives who say they don’t believe in a fast transformation, but they are certainly getting ready behind the scenes. It is like a bottle of ketchup: You never know precisely when the ketchup will actually come out or the exact amount. But when it comes to electric mobility, the bottle is just being thoroughly shaken.

Much of the discussion harkens back to Freudenberg’s history, with the company starting out as a tannery and finally moving into high-performance plastics. Does something like this affect our everyday routines?

Schneider: We like to guide our customers through our company exhibit, to point out that we’ve made it through a great deal of change over our history. We’ve proven we can do it.

Zoppi: I believe Freudenberg demonstrates this every day. Now we’re ready to transform ourselves.

Schneider: That is something you can feel. For example, there’s the fact that the company was ready to invest heavily in fuel cells and batteries. We’re ready to tackle new projects. That encourages our employees. It is a signal. It makes us proud to move forward with our company.

It is like a bottle of ketchup: You never know precisely when the ketchup will actually come out or the exact amount. But when it comes to electric mobility, the bottle is now being thoroughly shaken.

Claudio Zoppi, Vice President Freudenberg Sealing Technologies, Werk Pinerolo (Italien)

So you aren’t afraid of change?

Zoppi: No, on the contrary. I think we live in exciting times. I would be happy to pursue this as long as possible.

When are you getting your electric car?

Zoppi: I think my next car could be a hybrid..

Schneider: My next car will certainly be an electric vehicle. If I even buy another one. Maybe I won’t need it.

Zoppi: Wait a minute. You can’t do that. We have to keep selling seals!

Schneider: That’s true, but perhaps for other applications.

Zoppi: (laughs) Look, that sums up electric mobility quite nicely. I’ve heard that the growth of bamboo is totally unobtrusive when it starts out. It sends out its roots and remains inconspicuous. Then it suddenly shoots up and spreads out.

Schneider: We have to be patient. As the old saying goes, “You can lead a horse to water but you can’t make him drink.” But we can keep the trough filled. That’s what we are doing.

More news on the subject E-Mobility

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new