Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

10.06.2020 | Story

How many Lunar Rovers are on the Moon?

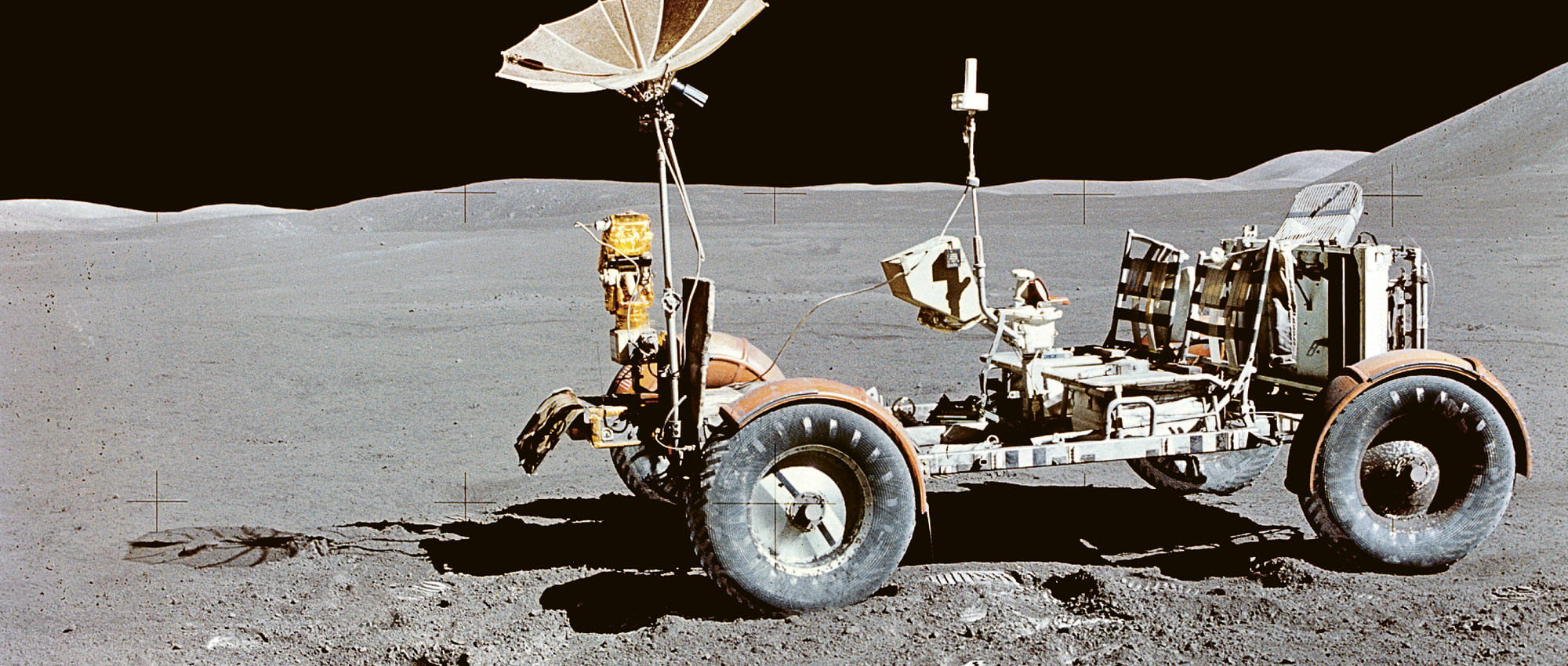

Astronauts didn’t just leave footprints on the moon’s surface – they also left three lunar rovers behind. And they happened to be great electric vehicles.

The Apollo 15 mission during the summer of 1971 was the fourth expedition to carry human beings to the moon. The American astronauts had a novel object on board: a Lunar Roving Vehicle (LRV). The homely buggy-like vehicle gave the space travelers a number of advantages: It greatly expanded their range of movement since it used energy sparingly and allowed relatively long stays out in the hostile lunar environment. It could also transport extra tools, making it possible for the astronauts to collect more samples from the moon’s surface.

Short Development Phase

The engineers assigned to the LRV had just 17 months to develop the vehicle. It was a short timeframe compared to the 60 months needed for the astronauts’ spacesuits. The U.S. space agency NASA had been working on lunar vehicles for a fairly long time, but it was the moon landing during in the summer of 1969 that accelerated the project. The Apollo 14 mission in February 1971 underscored the importance of this type of vehicle. The astronauts on that mission had to use a kind of handcart during their excursions, which proved to be difficult and time-consuming.

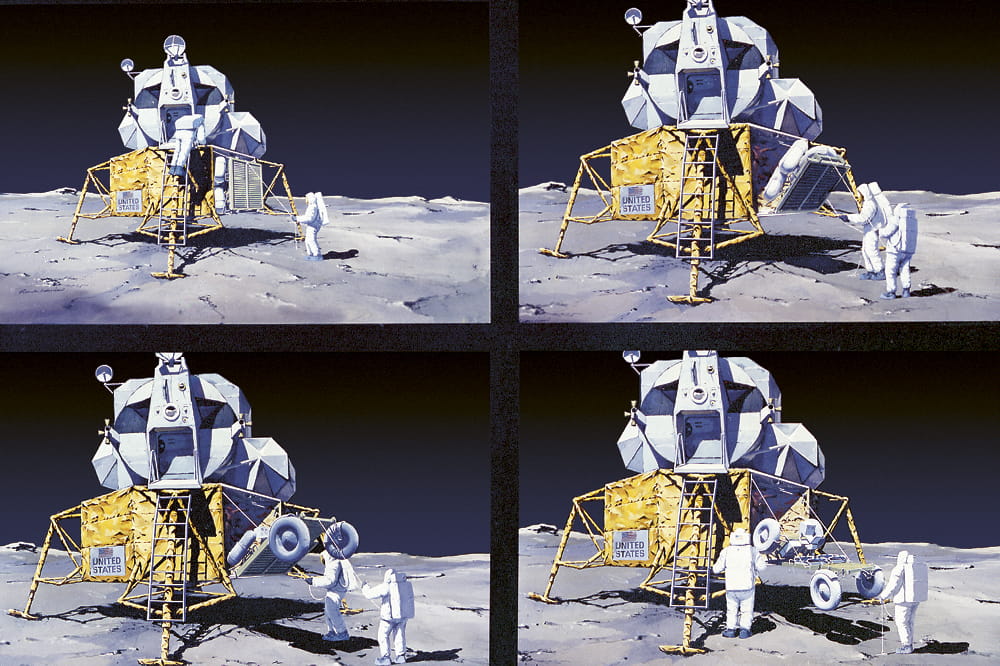

A Collapsible Solution

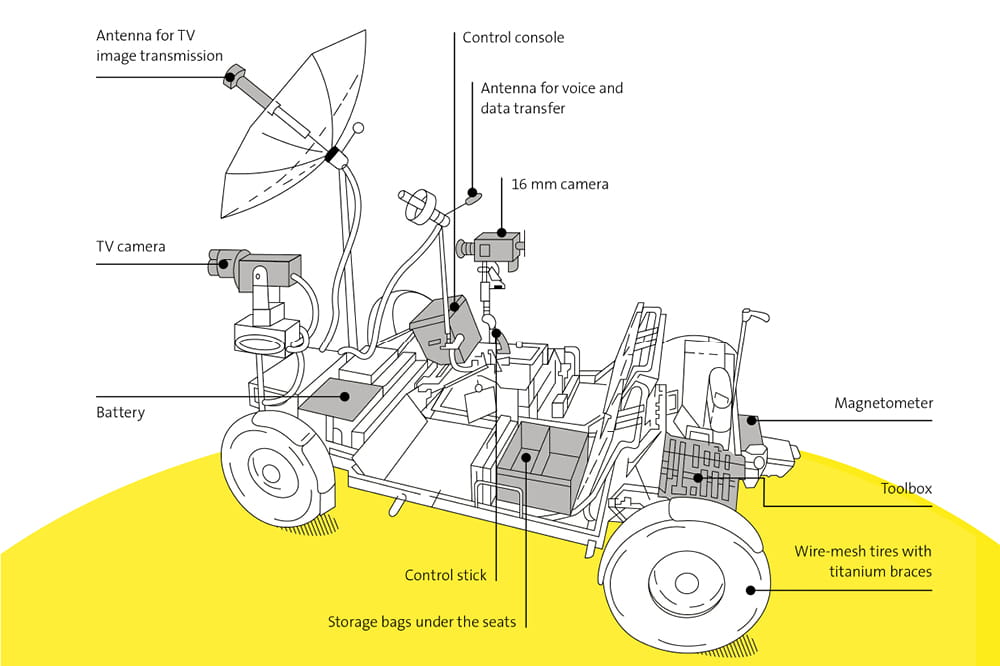

Boeing won the bid to develop the lunar vehicle in the fall of 1969. NASA provided concrete specifications, and General Motors and other U.S. companies also took part in the $38 million project. The vehicle had to be highly reliable and safe. It also had to be lightweight, which is why metals like aluminum and titanium were used. Once complete, the lunar rover weighed just 210 kilograms (463 pounds), but it could transport significant additional weight. Since there was no room for it inside the lunar module, it had to fit into a triangular chamber between two of its feet. The solution was a foldable chassis with slanted tires that unfolded almost completely by itself themselves when the chamber was opened. The LRV consisted of an undercarriage, four wheels made of a dense mesh of galvanized steel wire, two seats, and superstructures containing instruments and drive systems.

Navigation System

Fly me to the moon: The Apollo 15 mission during the summer of 1971 had a novel object on board: a Lunar Roving Vehicle (LRV).

Despite its spartan appearance, the Lunar Rover had ground-breaking systems onboard, including a navigation system. It gave the astronauts a direct route back to the shuttle if they traveled out of sight. The system is based on a directional gyroscope unit aligned with the lunar north, supported by a position indicator and solar-shadow tracking device. It uses lunar north and the sun as key reference points.

The Search for the Right Propulsion

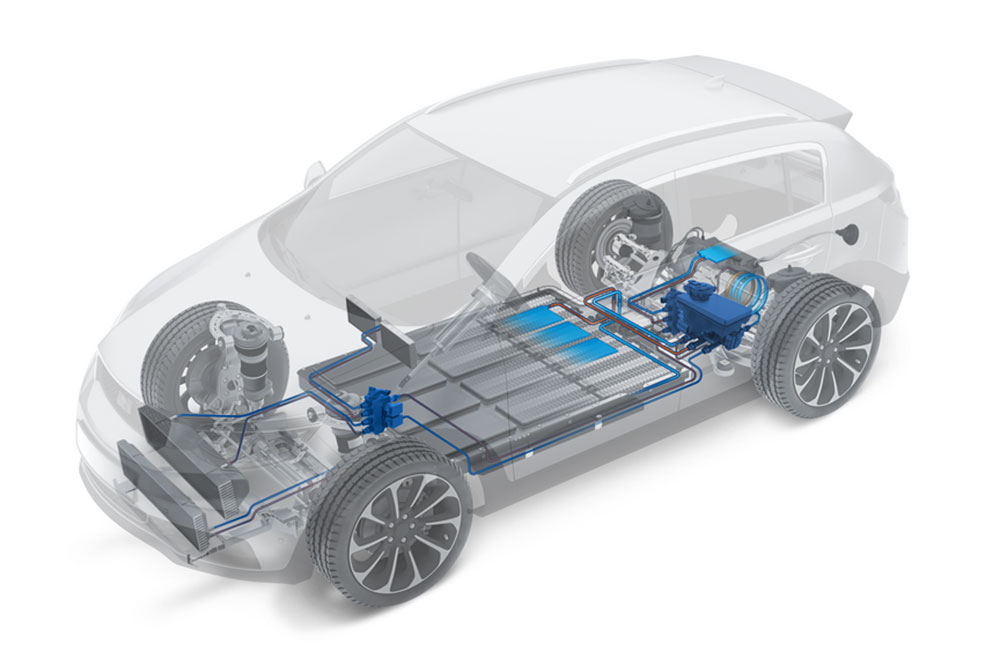

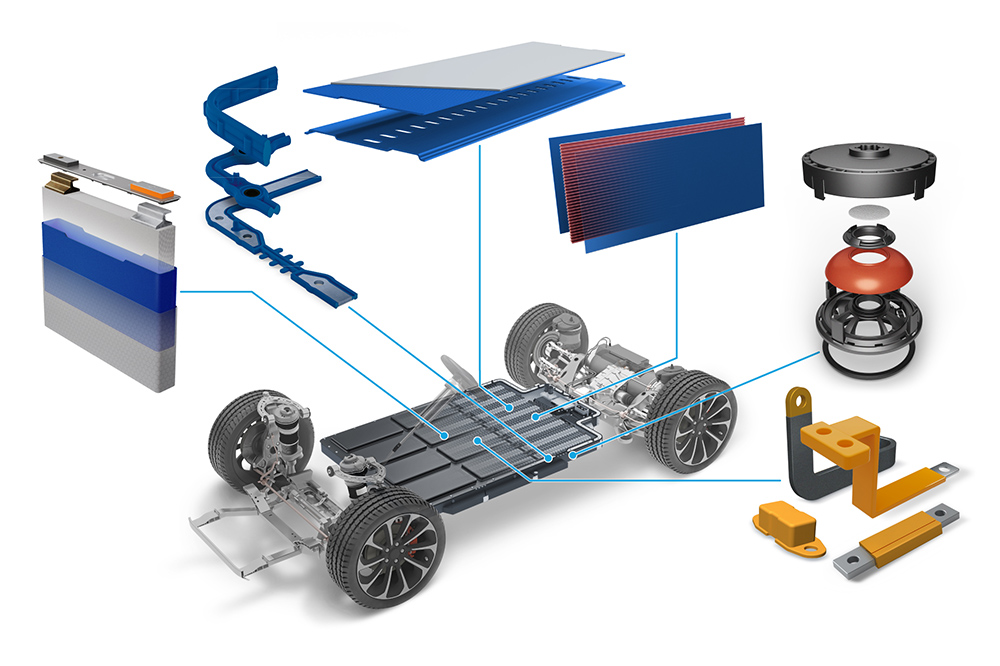

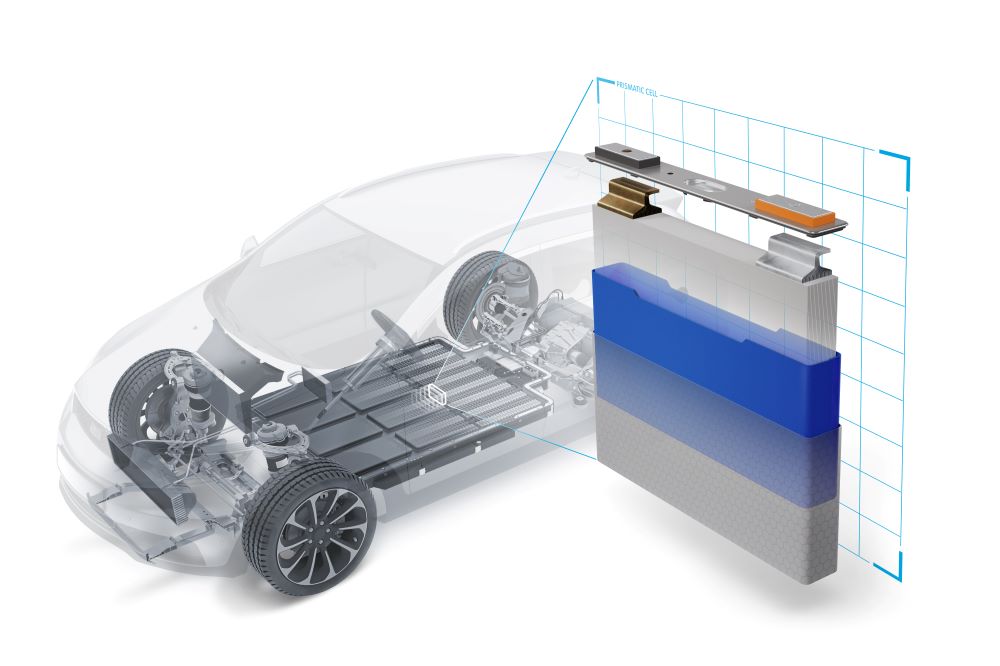

But how would the drive system actually work? Several scientists had already addressed that issue before NASA did. Their concepts involved rocket fuel, hydrogen peroxide and hydrogen, which were supposed to deliver energy by means of gas, or steam turbines or fuel cells. But NASA had a different form of propulsion on its wide-ranging specifications list: a battery drive system in which each wheel would be powered by an electric motor. The lunar rover was going to be an electric vehicle.

Electric Motors in the Wheels

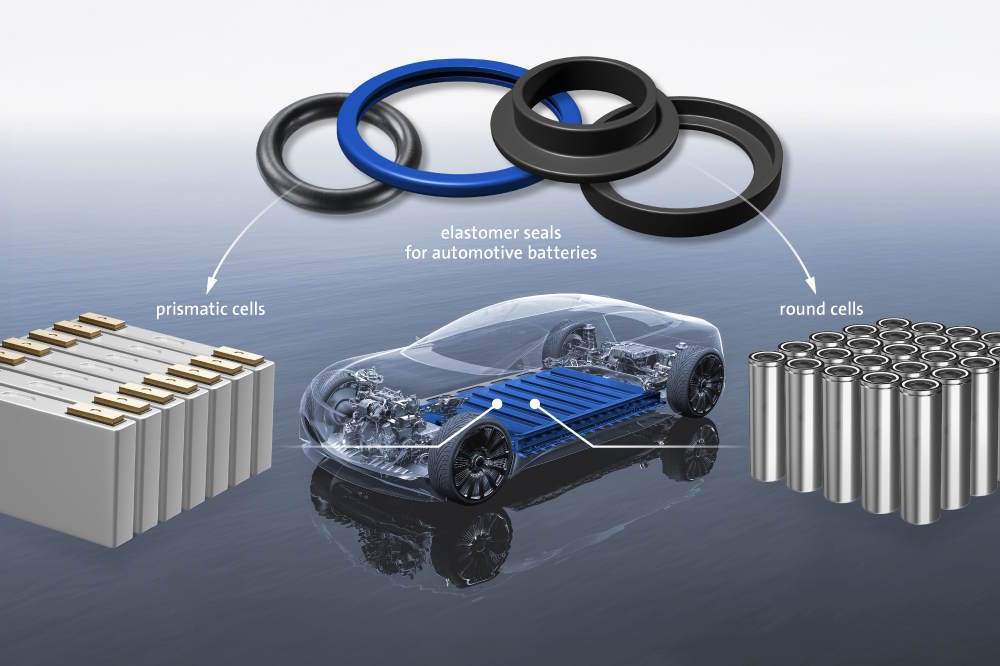

In the end, two 360-volt, silver oxide-zinc batteries would propel the LRV. They featured low self-discharging at a comparatively high capacity and a low power-to-weight ratio. NASA had already used batteries of this type on its lunar module. While one of the two non-chargeable batteries provided the LRV’s independently controllable axles with energy, electricity from the other flowed into the wheels. In its hub, each contained a 180-watt, direct-current electric motor with an output of 0.25 horsepower. This guaranteed that the vehicle could still be driven even if several motors broke down. If one battery ever malfunctioned, the other would take over its tasks. One key function was managing battery temperatures, as the surface of the moon ranges from -155°C (-247°F) to +120°C (+ 248°F). Multilayer insulation and wax boxes helped to regulate battery temperatures.

Still Drivable

The three lunar rovers from Apollo 15, 16 and 17 are still on the moon. They covered a total of 90 kilometers (56 miles) during their missions and completely fulfilled the expectations for them. No astronaut has ever expressed the need for their improvement. Today, one of their developers, Ferencs Pavlics, would merely make changes to their batteries and electric motors. In those cases, today’s enormously compressed energy and the progress that has been made in efficiency and weight are too significant to ignore. Still, the lunar rovers are likely to be drivable even today and would merely need to be supplied with a few new components.

More news on the subject E-Mobility

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new