Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

07.12.2021 | Story

Seeds of Innovation Have Long Been Sown

Autonomous vehicles could make farming more efficient and precise. But the components of machines that could be operating 24 hours a day are facing entirely new quality requirements. So it’s all the more important for seals to provide long-term protection.

Agriculture is under pressure, and it has been for a while: More and more food is supposed to come from the same parcel of land to feed a growing population, even as farming becomes more sustainable and efficient. This is achievable, but it will require new technologies such as robotics and digitalization. Autonomous vehicles reduce the need for farm labor, and networked devices could help with data management, enabling seeding, fertilizing and harvesting to become even more efficient. Well-known manufacturers and startups have been equally diligent in their research in this area. “A lot of things currently happen in the market,” said Markus Bedic, Global Key Account Manager for the Agriculture and Construction segment at FST. He provides support to numerous customers in the segment and has observed how the early developments in autonomous farm equipment got their start about five years ago. As a farmer might put it, the seed has long been sown.

Controlling vehicles ties up valuable manpower: The autonomous tractor from Case IH (CNH) could change that. The cabless concept vehicle finds its own way around - and can even drive together in fleets. © CNH Industrial Deutschland GmbH

Certain specifications have to be met for the work to bear fruit: Autonomous vehicles used in farming ideally have to be able to find their own way, avoid obstacles like utility poles, trees and vehicles, and connect with other machines when collaboration is needed. After all, farming often requires the use of different specialized vehicles. Or machines that share the work. “Think about a harvester, for example,“ said Mauro Lasagno, Global Key Account Manager, who services agricultural vehicle manufacturers in North America. “Fleets of vehicles often drive over the fields simultaneously.”

Large Tractors and Small Swarms

Manufacturers are moving in different directions. For example, Case New Holland (CNH) in the United States is developing and testing autonomous tractors that resemble current models but require no driver – or operate as hybrids, meaning that they can function independently but still have a seat for an operator. The seat may come in handy. Farmers may want to decide for themselves when it would be better to take over control for a while, since tractors have a wide range of uses. Much like other robotic applications, this autonomous helper is good at operating accident-free and conserving resources. A human is more flexible when the work goes beyond standard uses.

The German manufacturer Fendt has chosen to develop small, autonomous vehicles – Xaver robots – that are waist-high at most and work in the fields in groups, as intelligent swarms. “The farmer can operate these autonomous vehicles from his office,” Bedic said. He can also coordinate his tasks better and control them more precisely using the data collected from the vehicles and based on geo-referenced records. “When the robot sows the seed, the location and time for individual seed can be recorded.” The result is a trove of data for farmers. Concept vehicles from the two manufacturers are now crisscrossing fields. In parallel, numerous relatively small startups are positioning themselves in the market. The young companies are mostly banking on smart IT concepts or niches, much as they do in logistics, the auto industry and other sectors. One example is an autonomous harvester for steep, difficult-to-access vineyards.

24-Hour Operation

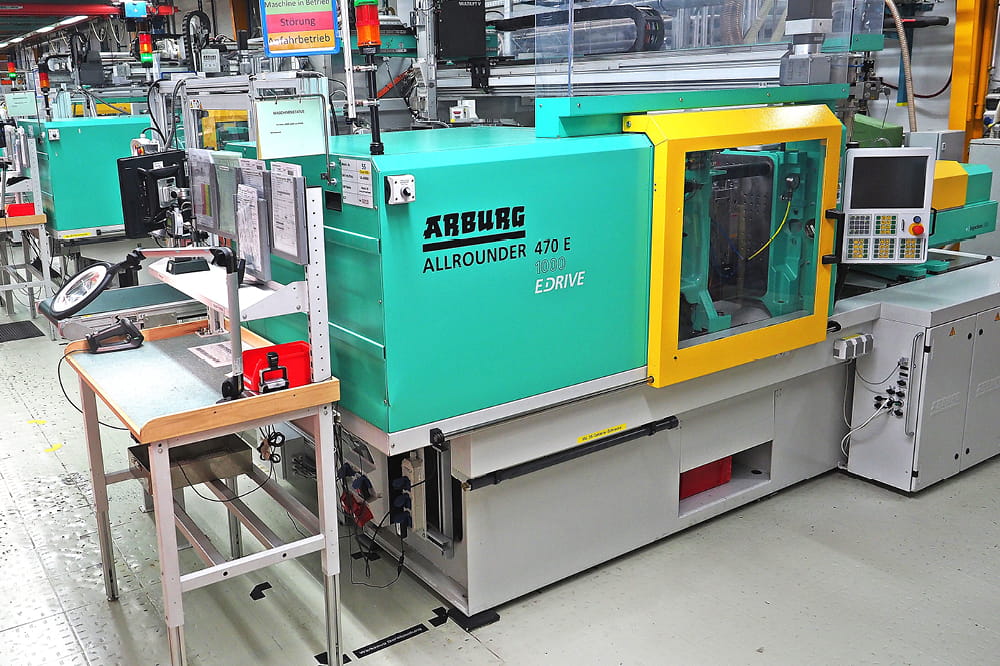

Not only farming will change with the arrival of autonomous tractors. The requirements for the machines themselves are evolving as well. Or more precisely, the requirements for their components. “When we consider the large tracts of land in North America or Brazil, these vehicles will never stop while they are doing certain kinds of work,“ Lasagno said. “During the harvest, they will literally be in operation 24 hours a day.”

Breakdowns due to the failure of individual parts would be fatal and disrupt schedules, so these autonomous machines are all the more dependent on high-quality components. . For years, Freudenberg Sealing Technologies has worked closely with manufacturers to guarantee quality – and moved in new directions in the process, as Lasagno explains: “In Brazil, for example, we helped to equip an existing CNH tractor model line with piston instead of hydraulic accumulators. This makes it possible to drive the tractors three times as long during the sugarcane harvest.”

Collaboration on this technically demanding level requires mutual understanding and know-how, Lasagno said. Ideally, this would lead the customer to gear its new models to the new components. Lasagno is confident that manufacturers of autonomous farming machinery will especially appreciate Freudenberg seals. “There is usually a great deal of dirt and dust involved, making high-quality seals to protect gearboxes and axles all the more important.”

Autonomous Helpers in the Fields

It’s clear that autonomous equipment will soon be driving across tracts of farmland. The indications are that large operations, in particular, are betting on robotic solutions. “Perhaps we will be seeing greater vehicle specialization,” Bedic said. Based on experiences with robotics in other sectors, autonomous machines are especially good at handling tasks that are defined as clearly as possible. The farmer can then concentrate on management. And now equipment producers can let their innovative ideas bloom. The seeds have already been planted.

More Stories About Digitalization

More news on the subject Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new