Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

26.02.2021 | Story

“By Engaging With Korea, ENGEL Became Global”

It’s not just large companies that are positioning themselves internationally today. Small- and medium-sized companies are setting up plants abroad as well. The machine-builder ENGEL ventured into Asia early on. There are a number of reasons for its success.

In the late 1980s, it was hardly normal for a small- or medium-sized company to venture into Asia. It was equally unusual for a 27-year-old to head its first subsidiary there, in Hong Kong, as it turns out. Robert Bodingbauer moved to the Far East as a young employee and has stayed there. Today, he is the Managing Director of ENGEL Machinery Korea. Several years ago, in recognition of his work, he received Korea’s Presidential Citation Award, its highest civilian honor. Still, “we had a bumpy start,” Bodingbauer recalled.

Evening atmosphere in Seoul: about an hour by train from the port of Pyungtaek, the site of the ENGEL facility. © ENGEL/Istockphoto: Cellena; efired

When Bodingbauer, who is Austrian, arrived in Hong Kong, he spoke little business English and found that it wasn’t very easy to transfer money from Austria to Hong Kong. That was the case even into the 1990s. While things have changed, investments abroad are still a financial challenge for small- and medium-sized companies. Planning is difficult as well. “The right team is crucial. That is the cornerstone,” said Bodingbauer, whom ENGEL appointed to run the plant in South Korea. It opened in 2001 and was the group’s first factory in Asia. “A production manager, a sales manager and a finance chief whom you can trust – you have to arrange everything, even if you can’t speak the language.” He apparently had a good feel for hiring and managing. Today his team has expanded to about 180 employees, including around 50 from the very beginning. Except for him, they are all Korean.

Indirect Impact on Headquarters

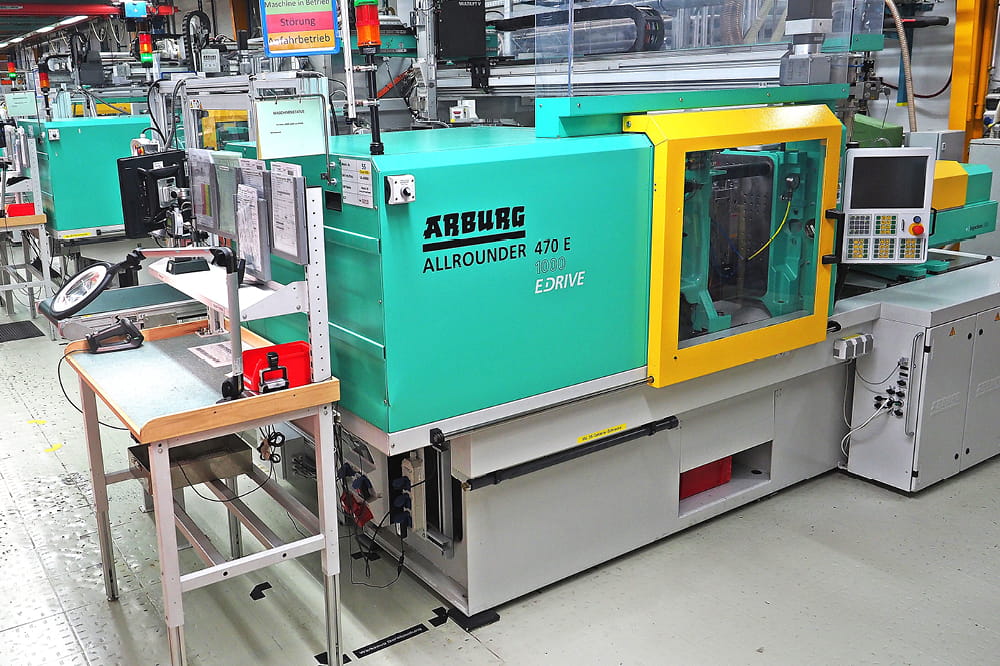

ENGEL deliberately set out to build machines in Korea with the same quality as those produced at its headquarters in Schwertberg, Austria. It builds injection molding machines and automation systems for the automotive and medical technology industries, among other sectors. “Some of our competitors wanted to have simplified machines built locally,” Bodingbauer said. “It was clear to us that local manufacturers would always be less expensive anyway, so we had to leverage our advantage with technology.” At the same time, the South Korean facility led to the company’s involvement with streamlined production or “lean manufacturing,” which had been employed in Japan for decades. “We were inspired – and we embraced it very early on,” Bodingbauer said. “There was a powerful indirect impact on the entire company.”

ENGEL ultimately managed to attract major Korean companies, including Samsung and the conglomerate LS Group, as customers. Right from the start, more than the Korean market was at stake. About 70 percent of the machines built in Korea are being exported to China and other countries in Asia. “Today, automakers with a global presence such as Hyundai and Kia use ENGEL equipment at their facilities worldwide,” Bodingbauer said. Once you earn the trust of a company’s headquarters, there are after-effects: “Plant managers at other locations see that our machine only needs a minute per shot during parts-making while another might need a minute and a half,” he said. “A technological edge helps.” ENGEL set up a plant in Shanghai in 2005 and reached revenues of more than 100 million euros in Asia for the first time in 2012. Today, Asia accounts for about one-quarter of the company’s global revenue. Even Chinese auto suppliers manufacturing in Mexico for the American market have become ENGEL customers. “Globalization can’t be stopped,” he said.

Close Cooperation

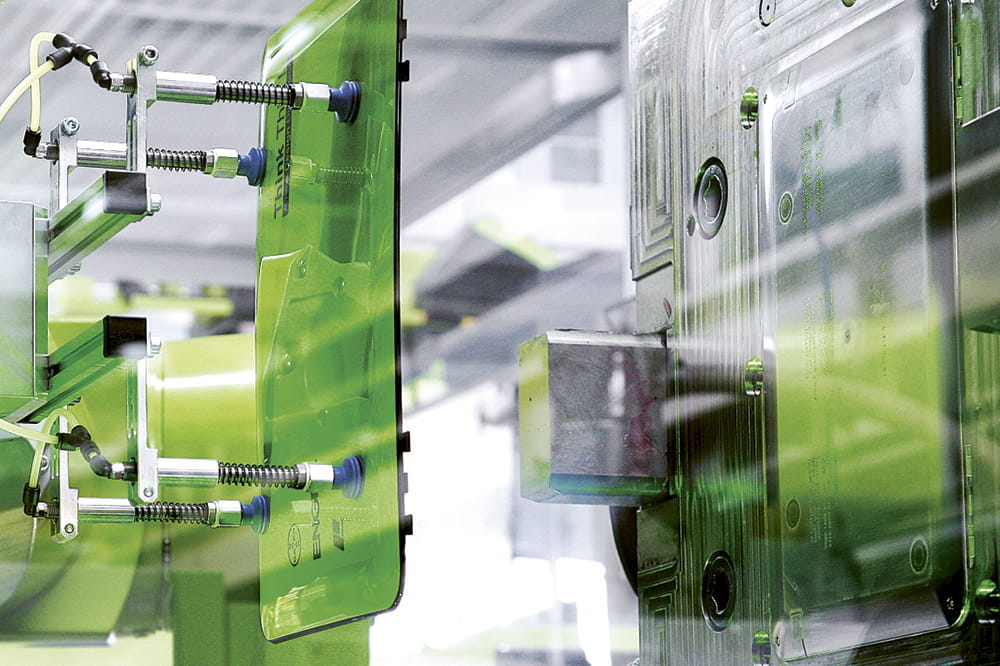

Freudenberg Sealing Technologies provides sealing packages for ENGEL’s hydraulic injection molding machines and is an important supplier of shaft seal rings to the company. Some of the concepts were developed in cooperation with ENGEL on an exclusive basis. Freudenberg also uses ENGEL products. Not just machines for multiple-component injection molding but automated systems as well, at the Application Center Integrated Precision Solutions in Losenstein and Emmerich, for example.

Expansion:: In 2013, ENGEL celebrated the expansion of its Korean plant along with customers, partners and local politicians. © ENGEL/istockphot: Cellena; efired

The Hard Work of Building Trust

The Austrian company doesn’t want to understate the difficulty of its early years in Korea. “You don’t create trust from one minute to the next,” Bodingbauer said. “Especially as a foreign company – we are viewed as such right down to the present even if I’m the only European at the Korean plant today.” Asia is a large, multifaceted continent, and his long experience in Hong Kong only helped him in limited ways. But he stressed that the Korea International Trade Association was quite helpful at the start. “Without them, we would’ve had much more difficulty with the many formalities.” The second key factor was respect, he said. “You should never forget that you are a visitor in this country. You can learn about a host country and its business culture, but you have to bring your own respect for its culture and people.”

Not everyone is capable of that, Bodingbauer has observed. Globalization has no doubt changed South Korea. “Cultures are growing closer together, and the younger generation thinks differently than their elders,” he said. Still, one should never assume that one’s own cultural expectations and moral concepts apply abroad as well. ENGEL’s decision to apply the same quality standards in Asia as in Europe is based on respect as well, Bodingbauer said. The requirements for high-quality products and innovative technologies are above all growing in Asia. Countries such as South Korea, Japan and China are very open to robotics and automation, he added. ENGEL has long built large equipment and special machines at its Asian locations. “The production costs are equivalent,” Bodingbauer said. Local parts and more streamlined organization on-site make up for extra expenses such as customs duties and transportation costs for components from Austria. From the beginning, the huge edge over the competition was the shorter delivery times for Asia. “At times, we were six to eight weeks faster than the competition,” Bodingbauer explained.

To a customer in New Zealand, it doesn’t matter whether the machine comes from Europe or Asia.

Automation: ENGEL develops process-integrated, automated injection-molding systems (e.g. for the production of laptop covers). © ENGEL/istockphoto: Cellena; efired

Spreading Risk for Customers

The corona pandemic of 2020 highlighted these advantages even more clearly. A debate is raging in some places about the risks to supply chains and “localization versus globalization.” According to Bodingbauer, the discussions overlook a fundamental point: “We spread the risks for our customers. Our plants support one another.” If the pandemic is hitting Europe especially hard, Asia can continue to produce and deliver – and vice versa. “To a customer in New Zealand, it doesn’t matter whether the machine comes from Europe or Asia.”

What counts most of all is the speed of delivery. If specific countries ban entry from certain areas, ENGEL may have a service representative who can enter the country from one home base or another. Bodingbauer then adds thoughtfully: “That is actually more difficult for our highly centralized competitors.” He doesn’t claim to have predicted global pandemics and complex supplier chains in 1986. But looking back, he thinks it was a good idea for the company to engage with Asia in a number of ways. “We are really well-positioned here.”

More news on the subject Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new