Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Micro Parts

Revolutionize Performance: Introducing Our Innovative Solutions

Discover Precision in Micro Sealing Products

At Freudenberg Sealing Technologies, our expertise lies in designing and manufacturing micro parts—valve components with external dimensions up to ~20mm. These precision-engineered products, molded from a range of elastomer materials including FFKM, FKM, and EPDM, cater to diverse chemical applications.

Sealing Challenges for Micro Sealing Parts

Challenges in micro part manufacturing stem from intricate designs and stringent tolerances, demanding precision, and reliability. Sealing these micro parts becomes pivotal to prevent leakage, ensuring optimal functionality and longevity. Our engineering prowess at Freudenberg Sealing Technologies meets these challenges head-on, leveraging cutting-edge techniques and materials. We excel in micro part development, boasting expertise in material science, advanced tooling, and meticulous manufacturing processes. Our commitment lies in crafting solutions that surpass industry standards, delivering unparalleled performance and durability.

Key Micro Sealing Parts Products Highlights

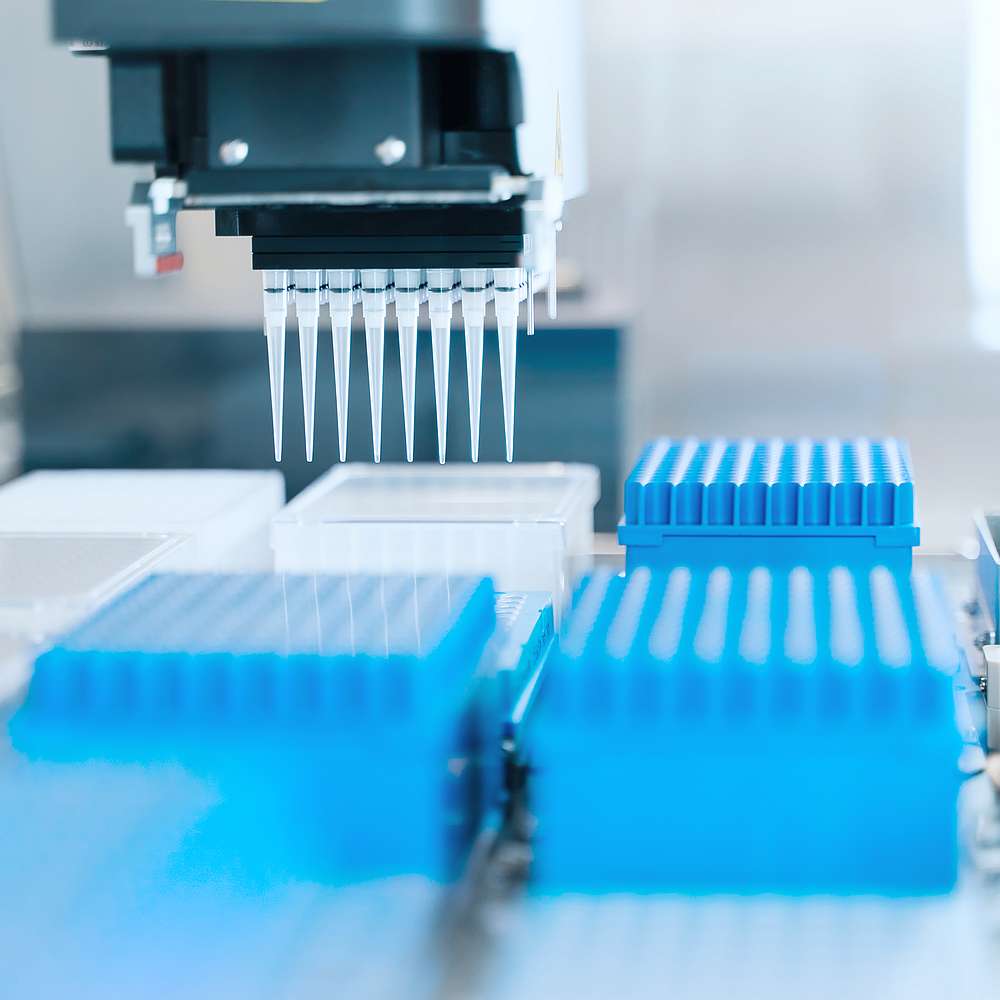

A picture of a clinical laboratory, showcasing the advanced technology of automation with a pipetting robot in action.

-

Unique Material Mastery

We excel in various compounds, particularly FFKM, FKM, and EPDM, tailored for distinct chemical and environmental needs. -

Unparalleled Precision

Meeting tolerances of ±0.03 mm with cmk = 1.67—exceeding ISO 3302 1 M1 standards—our products ensure reliability and consistency. -

Versatile Applications

From fluid handling valves, pumps, and mixers to small electric engines, our micro parts drive efficiency across industries. -

Innovative Design

Our commitment to innovation extends to tool concepts, where we craft bespoke solutions that balance quality and cost-effectiveness. -

Collaborative Solutions

Our seasoned team of experts in material engineering, product development, and process technology collaborates closely with clients. We tailor solutions to meet your unique needs, ensuring customer satisfaction at every step, e. g. design optimization by FEA (finite element analysis) with FST materials.

Innovative and Tailor-Made Micro Parts Sealing Products

Micro Simmerring®: Precision Sealing for Miniaturized Shafts

As industries move toward miniaturization, the demand for precise sealing solutions is increasing. Freudenberg's Micro Simmerrings® stand out as reliable seals tailored explicitly for small shafts, showcasing customer-specific designs and elastomer materials adept at meeting diverse requirements. These seals offer versatile sealing for rotary shafts, spanning inner diameters from 1 mm to 3 mm. They excel in sealing oil, food-compatible detergents, and aggressive media within a temperature range of 40 to 200°C.

Customers benefit immensely from these Micro Simmerrings® through enhanced durability, extending product lifespan and reducing maintenance costs. Featuring a springless elastomer lip design, these seals minimize friction torque, ensuring efficient performance. Developmental efficiency is a hallmark, progressing from pre-development stages to serial production within nine months, catering swiftly to evolving needs. Notably, their exceptional performance includes a dry running capability and minimal adhesion, even in dry conditions, ensuring unparalleled reliability.

Their resilience to chemicals is commendable, achieved through high-performance elastomers like XP and Simriz.

Their advantages are numerous: boasting functional excellence with a tribological pump effect, embodying a hygienic product design, and delivering impeccable performance without detectable adhesion, be it in wet or dry starts. The seal undergoes strict tests for endurance, and they are easy to use because they do not require any tools to put together.

Rocker Valve Seals

Freudenberg Sealing Technologies' Rocker Valve Seals exemplify meticulous engineering, crafted for precision and reliability in demanding environments. Each seal embodies an elastomer composite part functioning as a static seal with a bead, accompanied by two dynamic seal pads to enhance operational efficiency. The seal comprises a precisely engineered plastic carrier part with bearing bore, guaranteeing optimal performance within rocker valve systems. The rocker valve seals can be produced out of one single tool with different elastomers (e. g. FFKM, FKM, EPDM) suitable for dedicated applications.

Rocker valves, known as critical components within several applications for laboratory and analytics, are pivotal for regulating media and gases. In this precise environment, proper sealing is paramount to prevent any leakage during processing, ensuring optimal function efficiency.

You can rely on our seals to provide exceptional sealing capabilities, ensuring prolonged durability and increased efficiency in your rocker valve systems. Their adaptability extends to 2/3-way valves in microfluidics, medical technologies, and laboratory environments. Anticipate reliable and long-lasting sealing solutions customized to meet the specific demands of these specialized industries.

Brake & Seal Disc

Innovating within dental drill technology, Freudenberg Sealing Technologies presents a remarkable advancement in miniaturization of brake & seal discs. These drills incorporate a specialized seal that serves a dual role: preventing liquid infiltration while also acting as a critical brake to swiftly halt shaft rotation within a second for enhanced safety measures. Operating as air-pressure turbines, these dental tools achieve incredible rotational speeds of up to 350,000 rpm.

Precision is paramount in this specialized development: the demanded lip thickness achieved during manufacturing, measuring a mere few tenths of millimeters, accompanied by a manufacturing tolerance in the hundredth range, serves as a testament to the attained process accuracy.

Brake & Seals discs within dental drills have relevance and application within dental equipment and devices, especially in dental drills used within dental practices and clinics. These drills, operating as air-pressure turbines, rely on this seal to prevent liquid ingress into the drill and to function as a safety brake to swiftly halt shaft rotation.

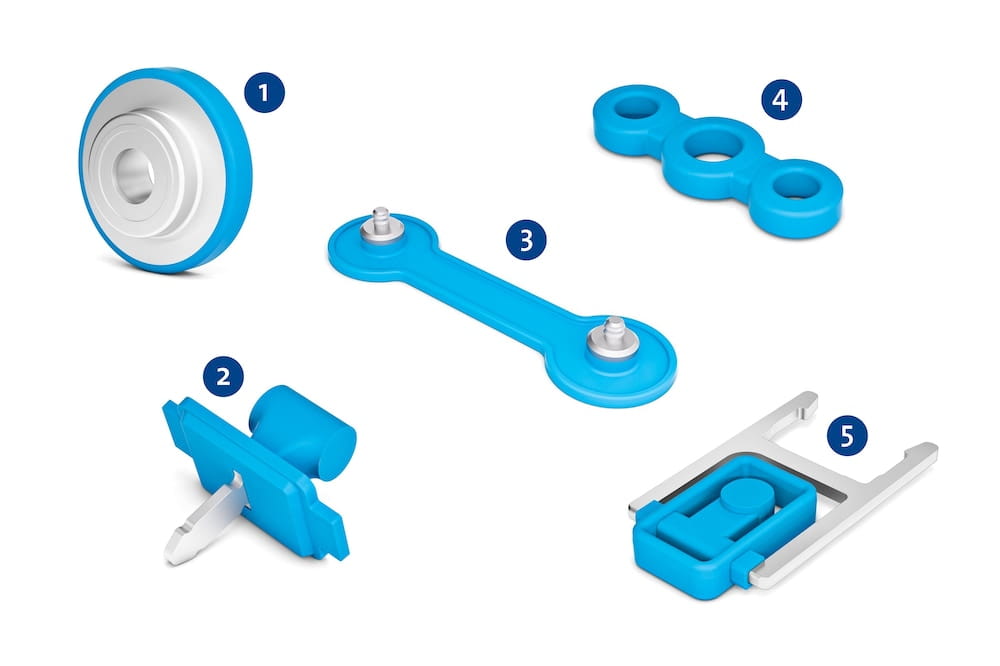

More of Our Reliable Micro Parts Sealing Products

We offer a variety of micro parts sealing products, all designed with high accuracy to suit the specific needs of different industries. Whether it's Flipper Valve Seals or O-rings, our products have excellent performance, reliability, and durability, ensuring the best function and lifespan, e.g.:

① Valve Seat

② Hammer Seal

③ Valve seal with vulcanized metal plungers

④ Static Micro Seal

⑤ Flipper Valve Seal

Interested? Our experts will be happy to answer your questions. Get in touch with us today.

Our Micro Parts related Services

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!