Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Power Tools

Sealing Solutions for Power Tools

Power for Your Workmanship

No matter whether it’s a rotary hammer, a grinding machine, a chain saw, a high-pressure cleaner or a lawn mower. No matter whether it’s powered by electricity, petrol or compressed air. No matter whether the power is wired or wireless.

Sealing solutions and components from Freudenberg Sealing Technologies always help make work with power-driven tools easier, faster and safer. Thanks to their unique material and design expertise, they combine maximum performance with long service life and service life in a wear-resistant, heat-resistant, PAH-compliant and cost-efficient manner. This benefits companies and specialists in trade, construction and industry as well as ambitious DIY enthusiasts.

Depending on the requirement, there is the option of a very wear-resistant HNBR with different hardness (application at higher temperature of 120˚C-150˚C). Furthermore, this material has very good bumping properties.

Reducing, Integrating, Optimizing

Reduce weight, size and cost. Integrate multiple functions into one part. Optimize ergonomics. Maximize speed, performance and durability. Guarantee global availability.

The demands placed on all types of power tools, from electric cordless screwdrivers to gasoline-powered lawn tractors, are constantly growing. Freudenberg Sealing Technologies has the development and technology expertise, innovative strength and global presence to offer industry-, region-specific and customized solutions. Completely independent of the drive technology of the tool.

Solutions for Power Tools Batteries

Discover the power of battery technology for outdoor work with Freudenberg Sealing Technologies. Our innovative sealing solutions protect the battery housing from dust, dirt and moisture, while our 2K design adds an extra layer of safety and simplifies customer assembly. For lithium-ion batteries, our thermally conductive high-performance plastic holders enhance thermal management and give you more power, faster charge speed and longer run times.

The Products in Detail

DIAvent®

The DIAvent® product portfolio offers a spectrum of solutions including bidirectional pressure equalization, emergency degassing during a worst-case scenario – the thermal runaway of a cell. Click here for more information.

Thermally Coductive Plastic Battery Holder

Our proprietary High Performance Plastic solution can deliver a high heat transfer coefficient to improve thermal management, allowing more power, faster charging and longer run time

Active Thermal Sleeves

Our heat shields thermally isolate neighboring cells to prevent or slow thermal propagation in case of a cell thermal runaway

2K Housing

Tolerance compensation during temperature fluctuations. Housings with seals integrated into the cover in a 2K design serve a greater purpose than just static sealing. A component with a permanent injection-molded seal is more suitable for automatic final assembly, therefore yielding additional efficiency potential.

Gaskets

Preventing intrusion of dust, dirt, salt and water into the battery housing, a large elastomeric gasket seals the entire perimeter of the housing cover and assists in containing thermal events. Smaller elastomeric gaskets seal access panels for components such as temperature control systems that optimize battery performance.

Constructional Powertools

Overcoming the toughest resistances with penetrating power, whether it’s made of concrete or stone: With seals and molded elastomeric parts from Freudenberg Sealing Technologies, drilling and demolition hammers are in the best hands. Robust and wear-resistant, they ensure 100% performance and a long service life for drilling, chiseling, tearing and removal. With the aid of first-class, PAH-compliant sealing materials developed and manufactured in-house.

More information can be found in the “Related Documents” section down below.

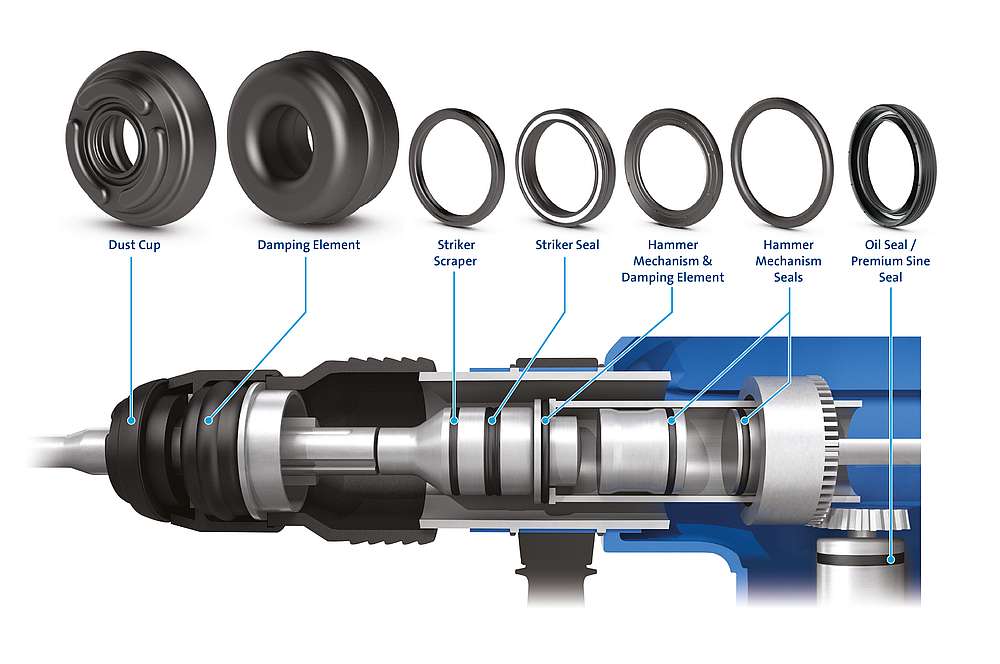

Sealing Solutions from Freudenberg Sealing Technologies ensure the performance and longevity of powerful hammer drills and demolition hammers. These tools are used for drilling, chiseling, tearing down and removing even the toughest of materials, such as concrete and stone.

The Products in Detail

Dust Cap

Original design with several scrapper edges and impact cams prevent damage

Damping Elements

Provide a long life span under harsh operating conditions due to innovative materials

Striker Seals

Constant contact pressure through two components seals hold in lubricants and keep extremities out for better performance and durability.

Striker Scrappers

Prevents axial movement of scrapper in the grove giving extra protection against dirt

Hammer Mechanism Seals

Reliable sealing with up to 80% reduction in friction compared to O-rings.

Oil Seals / Premium Sine Seal

Innovative seal lip design without spring, with sinus-shaped seal edge provides up to 40% less friction and double lifetime.

High Performance Plastic

These components offer reduced weight (50-80% less than metal bearings), reduced thermal expansion, and load-dependent friction reduction compared to common plastic components.

Whether it's cordless or corded electric, pneumatic with compressed air, or gas-powered - Freudenberg Sealing Technologies offers reliable, durable and energy efficient sealing and damping solutions that make using nail guns safe and comfortable.

The Products in Detail

Damping Elements

Proprietary Urethane and HNBR materials offer superior thermal resistance and lower internal friction allowing higher bumper cycles and energy absorption

T Rings

Reliable nail gun piston seal with up to 80% reduction in friction compared to O-rings

High Performance Plastic Wear Bands

Absorbs strong transverse forces of the nail gun piston while keeping frictional losses low

Solenoid Plungers With Meander Springs

Solenoid plungers with vulcanized sealing and damping hubs on meander springs allow minimal strokes with high frequencies, reducing space required at the same time

O-Rings

Six Sigma-quality O-rings feature a full range of materials for the most demanding operating conditions

Powertools for Forest and Garden

Sealing Solutions from Freudenberg Sealing Technologies keep your power garden tools running reliably and efficiently. From chainsaws to lawn mowers or robotic mowers, our products have been tested and proven to provide long-lasting performance. With our solutions, you can be sure that your power tools will work perfectly for years to come.

An increasing demand for more power and less CO2 emissions require a sealing partner with a large product offering compatible with most ethanol-based fuels and a wide variety of lubricants.

The Products in Detail

Oil Seals

Our oil seals deliver better performance and increased lifetime due to the advanced wear resistant FKM materials and designs. Freudenberg and Klueber collaborate to create the Lube&Seal technology offering a greased optimized design for lower friction.

Modular Plastic Sealing Concept

Designed for applications with low thermal strain and without pressure differences preferably in combination with plastic housing. A perfect solution for robotic mower wheels.

Solenoid Valves for Fuel Injection

Freudenberg solenoid plungers are precision molded seals used in valves for electric fuel injectors. The RFN™ Treatment for low friction helps to eliminate the “morning effect”.

Diaphragms for Carburetors

Freudenberg‘s patented Dispersed Fabric Technology for diaphragms allows greater freedom of design than traditional fabric reinforced elastomer solutions. The material is injectable and is comprised of chemically bonded fibers in an elastomer. Our elastomers are compatible with most fuels, including the ones with ethanol content.

Pressure Cleaners and Spray Guns Applications

Freudenberg Sealing Technologies offers a wide range of components for high-pressure cleaners to ensure surfaces are left clean and debris-free, regardless of the motor or drive type and whether it uses cold or hot water. Our selection of seals for modern high-pressure cleaners covers all types of applications and includes a variety of reliable solutions.

The Products in Detail

Oil Seal

Our oil seals deliver better performance and increased lifetime due to the advanced FKM design or high resistant NBR materials. Freudenberg and Klueber collaborate to create the Lube&Seal technology offering a greased optimized design for lower friction

High Resistant HNBR U-Cups

High resistant elastomer that meets the specifications for high pressure pumps. A perfect and more economical solution for fabric reinforced U-Cups

High Performance Plastic

Reduced friction depending on load and lubrication conditions, reduced weight (50% to 80% compared to metal bearings) and reduced thermal expansion compared to common plastic components

Urethane O-Rings

Our high tear resistant material with extrusion stability allows operation under high pressures for the lance and spray gun

O-Rings

Six Sigma-quality O-rings feature a full range of materials for the most demanding operating conditions

Accumulators

Energy efficient accumulators with high operating reliability and long service lives

Freudenberg Simriz® products, have been one of the preferred Perfluoroelastomer sealing solution by many Spray Guns manufacturers. The high quality of our SZ498, SZ495 and SZ485, offers a wide range of chemical compatibility at an affordable cost.

The Products in Detail

FFKM O Rings

The high quality of our SZ498, SZ495 and SZ485, offers a wide range of chemical compatibility at an affordable cost. Our product offering extends to O-ring catalog items and custom molded products.

Nozzle Seals

Simriz® perfluoroelastomer compounds accommodate a wide variety of nozzle sealing requirements and are also available in custom-molded shapes, from homegeneous designs to metal or plastic overmolded rubber.

Related Documents

-

FFKM Simriz® High Performance Material in Extreme Conditions

Unique Material Structure Provides Reliable Sealing Performance in All Environments.

-

Lube & Seal® for Power Transmission Engineering

Enhanced and prolonged sealing with Klüber Lubrication and Freudenberg Sealing Technologies.

-

Power Tools and Outdoor Power Equipment

With a global presence, Freudenberg seals and components are used worldwide in many power-driven tools from specialist equipment developed for trades, construction and industry to the tools designed for ambitious do-it-yourself enthusiasts.

-

Power Tools – Rotary Hammer / Demolition Tool

Freudenberg Sealing Technologies has been involved in the power tools market for decades and understands what really drives the industry.

-

New Polyurethane Generation

Freudenberg Sealing Technologies expands the boundaries of use with a new polyurethane generation to all standard and commercial polyurethanes.

-

Simriz® 495 - General Purpose FFKM Material

Simriz® 495 performs well in a wide variety of harsh chemicals as well as under overheated steam and hot water conditions. Especially its outstanding performance in strong acids and oxidizers makes Simriz® 495 the perfect match for nearly every application in the chemical process industry.

-

FNST Lithium Battery Heat Shields

Freudenberg Sealing Technologies heat shields are an easy-to-implement solution for improving battery safety.

-

FNST RFN™ Treatment

Sealing components made of elastomeric materials can have inherently high surface energies (tackiness) and a high coefficient of friction (COF).

-

RFN™ Treatment

Sealing components made of elastomeric materials can have inherently high surface energies (tackiness) and a high coefficient of friction (COF).

-

Solenoid Valve Plungers

Solenoid plungers from Freudenberg are available in numerous designs and have been tested to meet rigorous performance requirements for solenoid valves.

-

Modular Plastic Sealing Concept MPSC

Design for application in units with low thermal strain and without pressure differences preferably in combination with plastic housing for sealing of power units and gear boxes.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!