Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Bamboo - A Material on the Move

Bamboo – isn’t it breakable? Not any more than steel, to cite one example. This underappreciated natural material has been inspiring bicycle designers for a while. A survey of visionaries in Vietnam, Malaysia and California – as well as a German world traveler.

It is indeed strange that a Vietnamese engineer would be inspired, in Germany of all places, to use bamboo to build things. In 2009, Minh Tri Pham, then a student at the Berlin Institute of Technology, attended a workshop on bamboo bicycles. The idea fascinated him, and he was unable to shake it. Today Pham runs a company called “Vietnam Bamboo Bike,” in Ho Chi Minh City. As an engineer, he is above all fascinated by bamboo’s material qualities. “Various forces are at work when you ride a bike,” he said. “For example, the position of the pressure points is crucial when someone presses down on the pedals full-strength.”

Bamboo Bikers

Viet Bamboo Bike

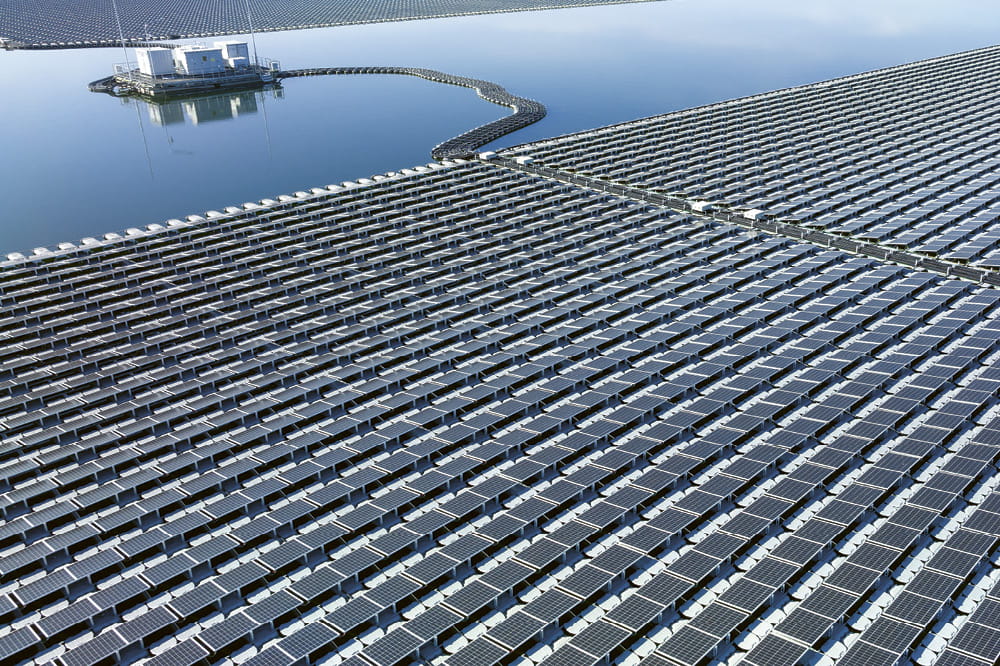

Minh Tri Pham founded his company as a side project. In his regular job, he works as an engineer in the renewable energy field. He now sells city and mountain bikes worldwide through his online shop.

Find more information about it: vietbamboobike.com

Bamboo Basti

Cyclist and activist Basti Gutmann launched his trip around the world from Munich in June 2017. As part of his plan, he resolved to plant 40,000 trees over the course of his trip.

Bamboo isn’t wood – it’s a grass. It consists of fibers grouped around a hollow form, separated by nodes. “The strongest fibers are exactly where the largest stress point prevails mechanically,” Pham said.

That gives bamboo extreme hardness combined with great tensile and compressive strength. It is an illustration of lightweight construction in nature. The material can’t compete with ultralight carbon frames based on weight, but it does very well in comparisons with metal. For bicycle frames, the bamboo is reinforced, heated and glued with epoxy resin at its joints.

Pham now manufactures his bikes for customers worldwide. That makes him part of a trend: Manufacturers are designing and selling bamboo bikes in other countries as well, and not just for stylish, leisurely excursions, but for racing and mountain biking, too. The first e-bikes are now available as well.

Basti Gutmann has subjected the material to a special stress test: In 2017, the German cyclist set out on a trip around the world on a bamboo bicycle he built himself. “On a whim,” he said. It has developed into a 37,000-kilometer (23,000-mile) trek. Traveling under the nickname “Bamboo Basti,” Gutmann was on the road nearly three years before the corona pandemic and its accompanying border restrictions stopped him in his tracks. Aside from being an advocate of sustainability, he is tinkerer and carpentry hobbyist. The fact that he chose a bamboo frame for his trip has more than just symbolic significance.

I want to build attractive, robust bicycles

Minh Tri Pham, Founder Viet Bamboo Bike

"Compared to carbon or other materials, bamboo is the easiest to patch. You only need an epoxy resin and hemp, which can be easily obtained anywhere, especially if you are on a coast." By contrast, steel or aluminum would have to be welded. Bamboo doesn't break apart like wood either; the fibers tear lengthwise, which does not affect its stability provided that the tears are promptly closed.

It was then that Gutmann realized there were more than a thousand species of bamboo with highly specific properties. “Ahmad told me with a grin that my bike was assembled extraordinarily well, but the bamboo wasn‘’t really suited for it. There were better choices,” he said. Gutmann rode his bamboo bicycle across the Balkans to India – and happened to meet a man in Malaysia who owned a large bamboo factory. Ahmad Mazlan Othman is an engineer, construction planner and visionary who also uses bamboo, in his case, for home construction.

Still, the bike had indeed carried him all the way to Malaysia. Ahmad Mazlan Othman is a bamboo activist. In his lectures, he especially stresses the sustainability of the material. Due to its rapid growth, bamboo binds up large quantities of carbon dioxide and, in the bargain, produces more oxygen than most other plants. Architects worldwide are increasingly discovering the material's advantages.

Compared to carbon or other materials, bamboo is the easiest to patch.

Basti Gutmann, German cyclist and activist

Minh Tri Pham tackled the promise of bamboo with a similar scientific approach. After his return to Vietnam from Germany, he identified 360 species of bamboo, and he has worked intensively on mechanical simulations since then. He has now settled on the species that are best suited for bicycle frames. The pandemic has slowed him down as well, but Pham has used the time for more research and development. “The designs are my strength,” he said. “I want to build attractive, robust bicycles” – with materials that do not have to be imported. Target group: Customers abroad. In Vietnam, the hot weather coupled with torrential rain discourages the use of bicycles as a daily means of transportation. But Pham finds that the number of active recreational cyclists is growing.

Craig Calfee of California is considered one of the world’s pioneers in bamboo frame construction. He first experimented with the material in 1995. Since 2005, he has been manufacturing bamboo bicycles professionally and advertises his current model as “more rigid than many carbon frames.” That is remarkable inasmuch as Calfee was one of the first in the industry to develop carbon frames in the 1980s, equipping Tour de France winner Greg LeMond with them, among others. Accordingly, his bamboo frames fetch a high price: between $3,000 and $5,000. Basti Gutmann also met Calfee during his travels, encountering him accidentally while he was looking for lodging. “Tomorrow I want to find that madman around here who builds bamboo bicycles,” Basti told him. “That’s me,” Calfee replied. Gutmann stayed with him for two weeks.

Rapid Growth

Bamboo grows quickly. Some species shoot up as much as 90 centimeters (about 35 inches) per day. The niche market for bamboo bicycles may not be growing quite as quickly – but buyers’ interest seems to have been awakened. “Bamboo can grow in a great many locations on the planet,” Pham said. From all appearances, the same applies to the interest in nature’s lightweight material.

This article originally appeared in ESSENTIAL, Freudenberg Sealing Technologies’ corporate magazine that covers, trends, industries and new ideas. To read more stories like this, click here.

More Stories About Sustainability