Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

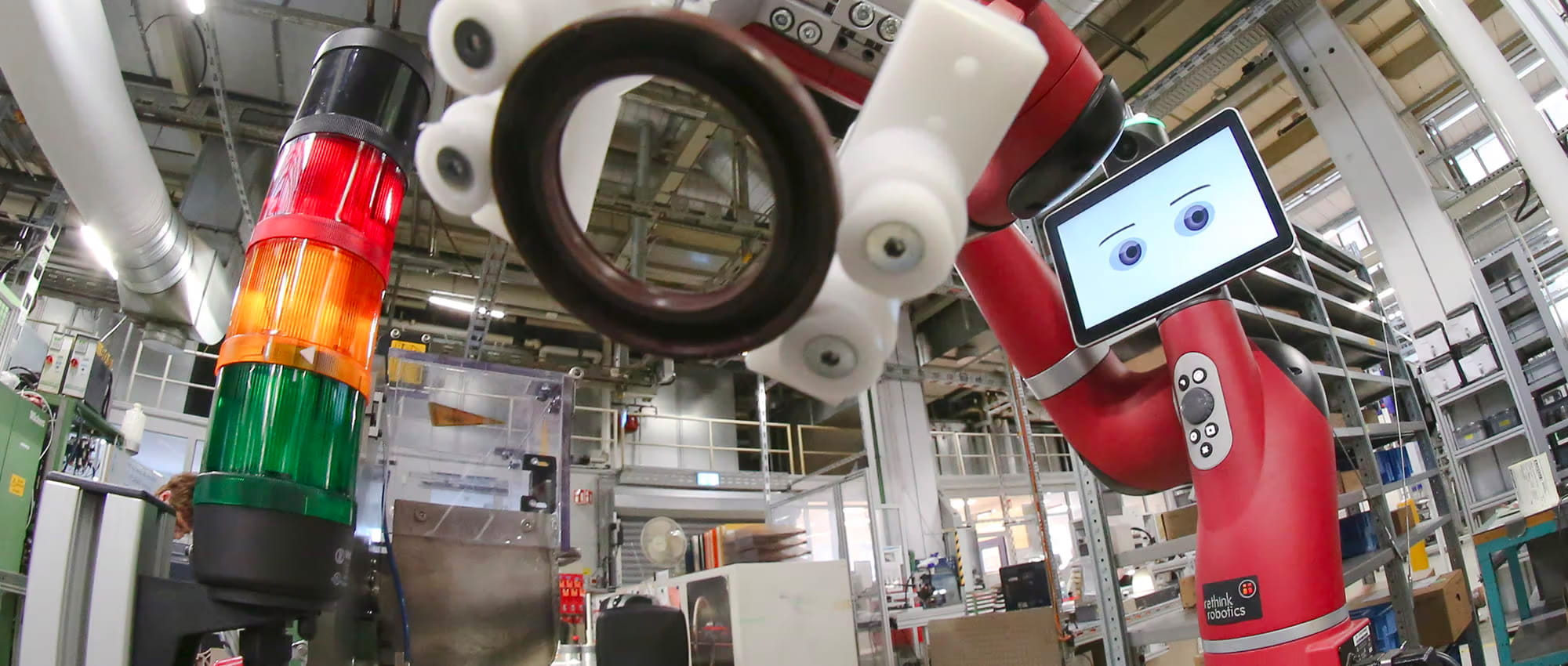

Operating Globally in a Robotic World

The market for industrial robots is growing more explosively than ever. The more their customers position themselves around the world, the more the manufacturers of robots are following them. The result: a truly global sector where new ideas emerge worldwide and special regional challenges have to be overcome. As a supplier, how do you keep an eye on them?

A typical industrial robot is quite heavy – and large. For that reason alone, it often makes sense for buyers to source robots from their own continent. At the same time, more and more companies have set up manufacturing operations around the world, and they need the same types of industrial robots, whether the plant is in Shanghai, Denver or Madrid. “Robot manufacturers have responded to the trend as well,” said Achim Ströhle, Global Segment Director, Heavy Industries at Freudenberg Sealing Technologies.

Japanese companies have reigned over robotics for years, and they still account for about half the sector’s market share. But Europe has been gaining on Japan lately. The signs of progress include the European Robotics Center in Denmark, complete with a cluster of related companies nearby, and the firms around the Technical University of Munich. The market is booming and continuing to diversify. “Even leaving aside household products such as robot lawnmowers for a moment, we would still be talking about a diverse range of robots in the sector today,” Ströhle said. “Industrial robots also include driverless transportation systems, service robots and cobots.”

Sales and Development Partnership Guarantees Short Distances

Robot manufacturing is global today. Companies with headquarters in Europe are developing and manufacturing in China, among other countries. And those with their headquarters in Japan are developing and manufacturing in Europe or the United States. If a supplier wants to be a reliable partner, it has to position itself similarly from a global perspective. “That‘s a challenge for any company,” Ströhle said. This is true, for example, when a specific sealing ring is largely produced in Europe, but the manufacturers of a particular type of robot are mainly located in a cluster in China. Freudenberg came up with an answer to these and similar issues six decades ago: its close cooperation with NOK in Japan. It was initially a technical partnership for the most part; today it is a contractually regulated sales and development partnership, complete with joint ventures. The two companies handle their domestic markets on their own. But they teamed up to conquer the U.S. market.

Today industrial robots are used in every area.

Achim Ströhle, Global Segment Director, Heavy Industries at Freudenberg Sealing Technologies

One specific example: NOK and Freudenberg Sealing Technologies support each other’s customers when they manufacture in the respective home regions. That means Freudenberg will be the supplier to a Japanese robot manufacturer that has an assembly line in Europe – and vice versa. Ströhle is sure this takes special qualities: “Of course, something like this only works if you have built up a strong relationship based on trust,” he said. The sales and development partnership has been in place for three years. He describes it this way: “We work together on issues that come up during our visits to customers. We derive trends from them and look for solutions appropriate for the industry.”

Demands on Materials Are Rising

There are some issues that only come to light when you take a wide-ranging, global look at the robotics industry. Paradoxically, what bothers some manufacturers today is the success of their sector. “Today industrial robots are used in every area, even in medical technology and the consumer sector,” Ströhle said. These specialized tasks may vary greatly, but the basic body and technology of a robot in car production and on the operating table can be absolutely identical. In turn, that means the demands on materials and components are rising. Much as a car could end up either in the Sahara or Canada’s frozen north, robots ideally need to meet the industrial standards of various sectors and fields of application right from the factory. One example would be increased moisture protection for seals: They must be absolutely reliable in preventing leaks. “This is a very interesting problem,” said Ströhle looking back. “Some customers have tolerated small leaks, in grease-lubricated housings, for example, as a given. We first became aware of how widespread this was when we were at a trade fair with some international teams and we asked manufacturers that were very different about the issue.” What isn’t a problem for one industry may be a nonstarter for another. In their development partnership, Freudenberg and NOK are determined to meet this challenge. It is a problem that no manufacturer has yet solved.

Robotics is a key topic in the future and a rapidly growing market.

Achim Ströhle, Global Segment Director, Heavy Industries at Freudenberg Sealing Technologies

“We Are Already on Site”

Freudenberg Sealing Technologies can present itself as a company that keeps an eye on problems from a global perspective and can draw on local expertise when necessary. And it can do so with conviction. This also applies if a robot manufacturer decides to shift part of its production to China or the United States. “We don't have to build a factory especially for the project – we already have a local presence,” he said. Not long ago, a robot manufacturer instructed its motor supplier to use products from Freudenberg Sealing Technologies – a success that can be attributed to its global presence and international partnerships. “The whole subject is not something to see as a short, quick project,” Ströhle said. “It pays off because robotics is certain to be a key topic in the future and a rapidly growing market.”

Read more about globalization in our next issue of ESSENTIAL. The ESSENTIAL, Freudenberg Sealing Technologies’ corporate magazine-covers trends, industries and new ideas. To read more stories like this, click here .

More Stories About Digitalization