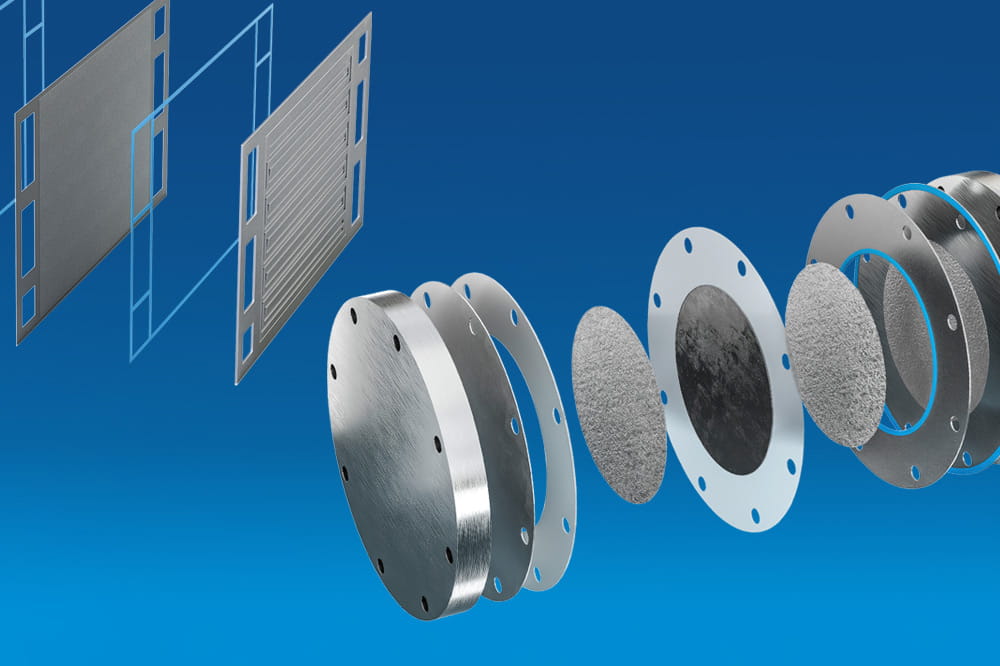

About Freudenberg Sealing Technologies

Our Organisation

We need to think ‘lean,’ which means getting every form of waste out of our processes.

Dr. Matthias Sckuhr, COO of Freudenberg Sealing Technologies, talks about lean processes, historic trends and the role of employees.

Your Career Starts Right Here

Career with prospects - Freudenberg Sealing Technologies offers

offers talented young professionals as well as experienced professionals

a wide range of entry-level opportunities in various fields of activity.

Committed to Protecting the Environment

Partnerships and Networks

Get in Touch

Do you have a question? Would you like a concrete offer? We are looking forward to your message.

Contact us