Machined Seals

Freudenberg Xpress® ‒ Customized Seals in Original Freudenberg Quality

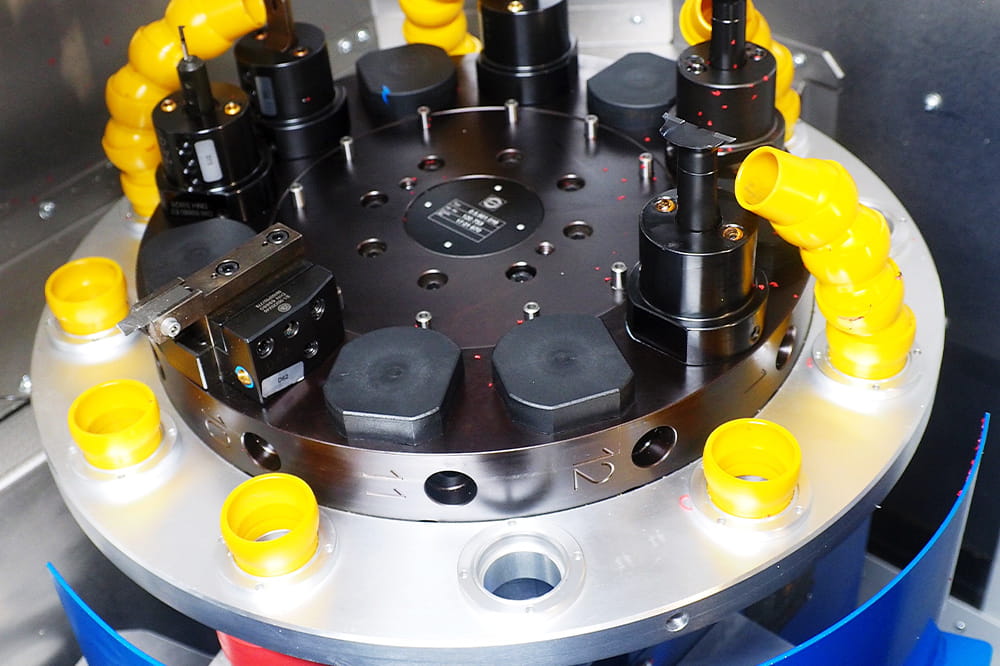

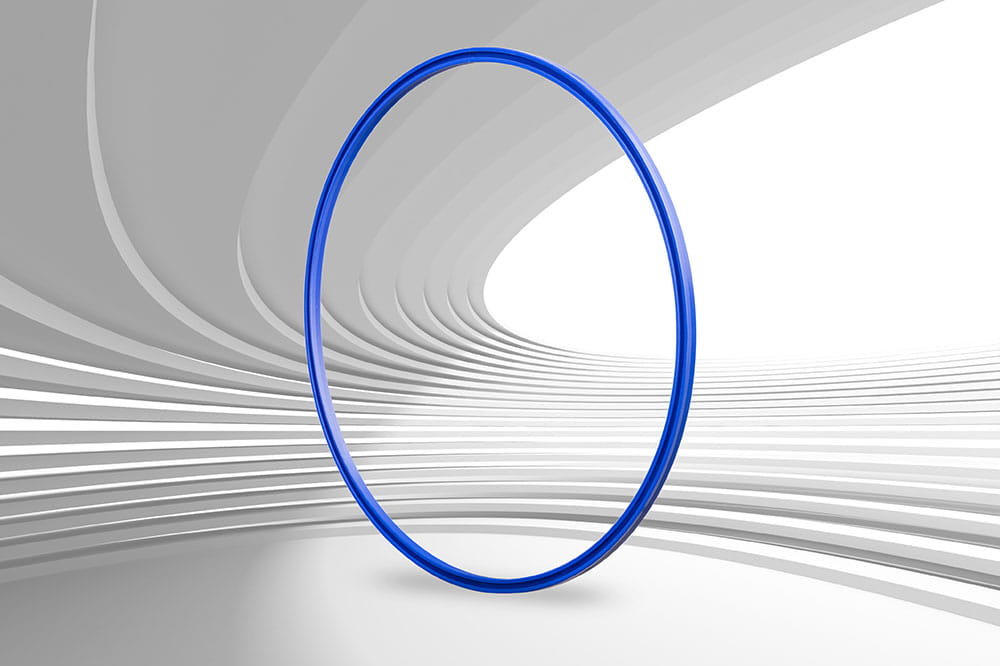

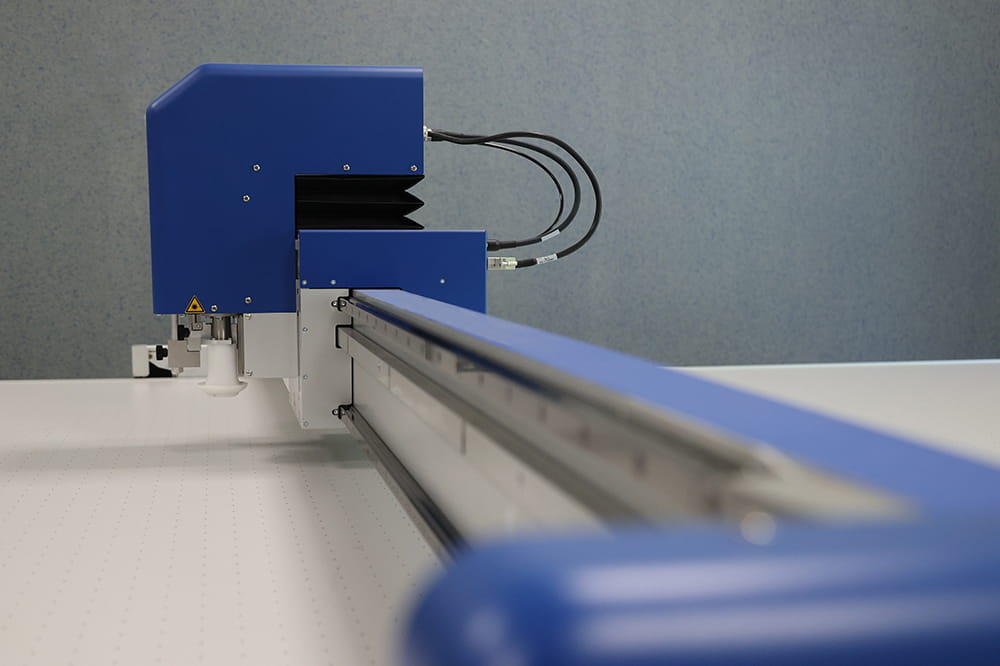

Freudenberg Xpress® minimizes your downtimes and maximizes your flexibility. As your partner for high-quality CNC machined seals, we always strive for the quality of series production; no matter if catalog parts, complex plastic parts, customized solutions, welded seals or cut-to-size products. We use the original Freudenberg materials and profiles for high performance. This way, Freudenberg parts can easily and quickly be replaced in existing systems. Additionally, customers benefit from a global network of service centers and manufacturing partners.

Your Advantages at a Glance:

-

Customized sealing solutions for Customer Satisfaction

-

Original Freudenberg profiles and materials as used in series production

-

Worldwide expert consultation

-

Fast delivery for quick maintenance needs

-

Efficient solutions for every part of a product’s lifecycle – from prototypes and individual pieces to small series

Get to know more about the registered trademark of Freudenberg Xpress® service.

Download Freudenberg Xpress® Brochure

Download Freudenberg Xpress® Poster

Virtual Tour

Discover the process from the first sealing need to the finished product made by Freudenberg Xpress®

Start now

Do You Have Questions About Machined Seals?

Our experts will be happy to answer your questions personally.

Write us your request and we will call you back.