Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

POM

What is POM Material - Excellent Chemical Seal Resistance

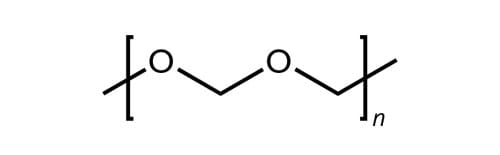

Polyoxymethylene is a high-molecular-weight thermoplastic. Hermann Staudinger discovered it in the 1920s as part of his investigation of macromolecules. In 1952, DuPont succeeded in synthesizing it. A patent was filed for the material four years later.

Polyoxymethylene is a semi-crystalline thermoplastic and is in particular used as a technical plastic for precision parts due to its high rigidity, low coefficient of friction and outstanding dimensional stability.

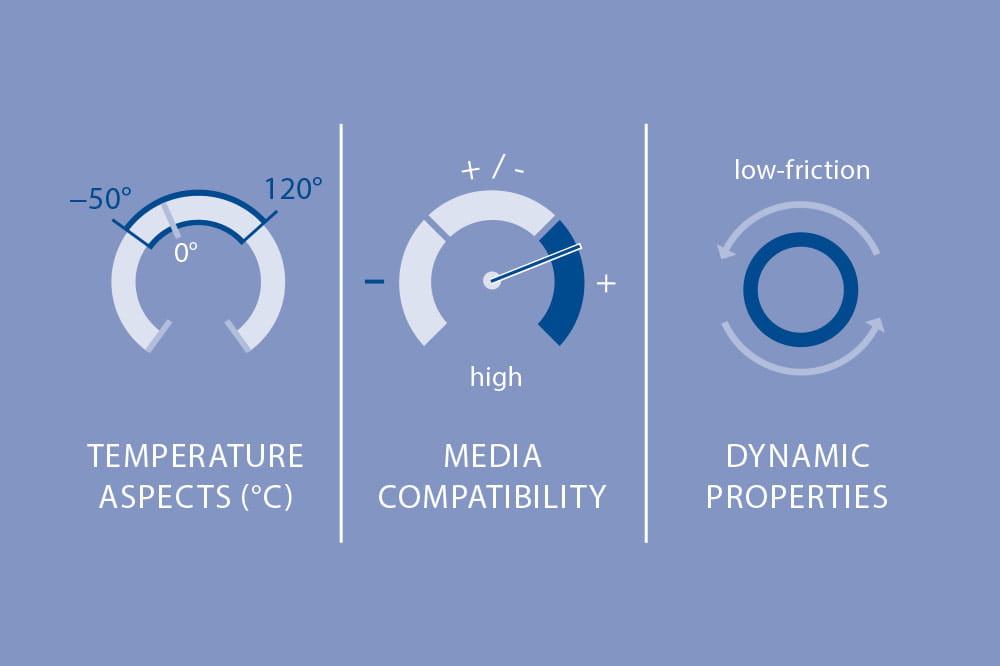

POM stands out for its high strength, hardness and rigidity over a wide range of temperatures. It even maintains its durability at low temperatures.

It shows high resistance to abrasion and only absorbs water to a low degree. POM’s good chemical resistance and low water absorption make it ideal for use in contact with foods. Many types also conform to FDA or German Federal Institute for Risk Assessment (BfR) standards.

Due to its high crystallinity, POM is more rigid and stronger than other thermoplastics, especially in the temperature range of −50 °C to 120 °C. At room temperature, POM has a pronounced elastic limit at an elongation of about 8%. Below this elastic limit, it displays a good resilience even with repeated stresses. So it is especially well-suited for spring elements. Its high stress rupture strength and a low tendency to creep round out POM’s advantages. POM’s mechanical qualities combined with its good frictional and wear behavior make it ideal for a wide array of technical applications in the processing industry.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!