Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

NBR

NBR Meaning - Nitrile Butadiene Rubber for Gaskets and Seals

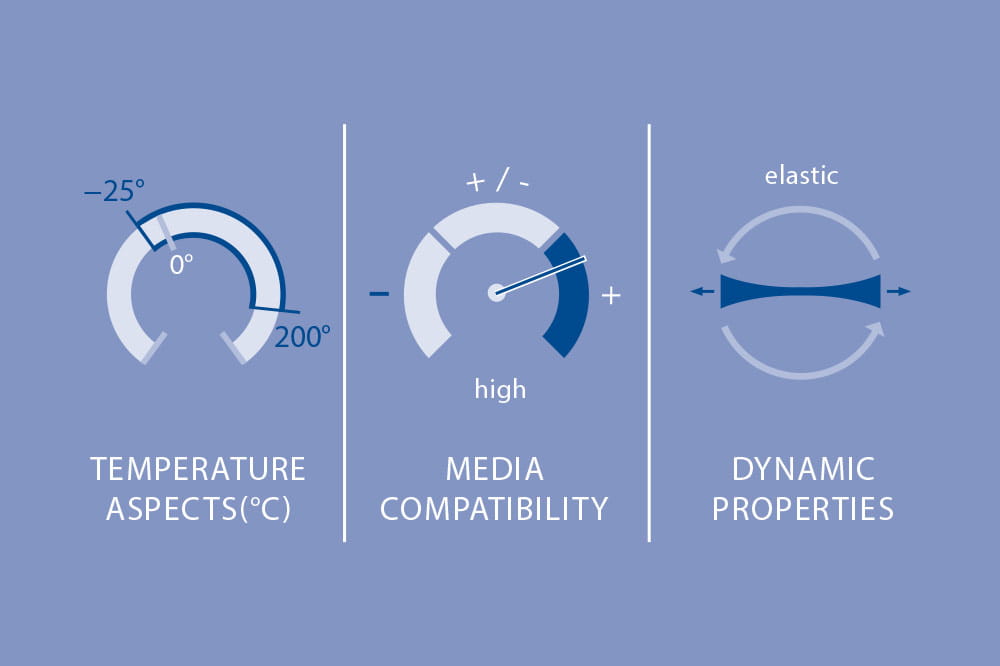

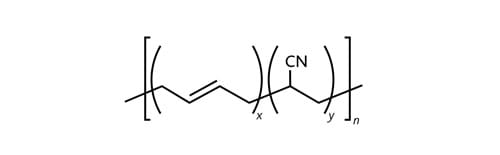

NBR is the abbreviation for nitrile butadiene rubber. This is a synthetic rubber that was developed during the 1930s. It is fabricated through the co-polymerization of acrylonitrile (ACN) (polar building block) and 1.3-butadine (nonpolar building block). Its attributes mainly depend on its ACN content.

The manufacturer can vary the content and thus produce different types of the material. In the process, the ACN content determines the balance between media resistance and low-temperature flexibility. Low ACN content produces a low glass transition temperature but also leads to greater swelling in oils and fats. As the ACN content increases, this behavior reverses direction – due to the polar components in the polymer.

Nitrile rubber exhibits superior mechanical strength with high elasticity as well as good deformation behavior in a temperature range between -30 °C and 100 °C. Its relatively low heat resistance can be traced to the presence of reactive double bonds. It is used for oil- and fuel-resistant seals such as Simmerrings, O-rings and frame seals. The use of NBR marked the arrival of elastomers as a sealing material particularly in general industry. It is also employed in the auto industry.

Due to its effective resistance to fatty media and its wear resistance, NBR is used in the process industry as well, for example, in diaphragms, pneumatic and hydraulic seals and radial shaft seals.

¹ Oil and water emulsions or solvents with a water content of more than 80 percent and concentrate based on petroleum oils or soluble polyglycols.

² Water-in-oil emulsions with water content of more than 40 percent and petroleum oil.

³ Water glycol with a water content of more than 35 percent and polyglycol solution.

Related Documents

-

55 NBR RD883

Freudenberg Sealing Technologies’ new 55 NBR RD883 nitrile butadiene rubber (NBR) is a high-performance material that meets stringent industry standards, such as ANSI/CAN/UL 144, for use in LPG regulators.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!