Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

10.03.2017 Press Release

Freudenberg Xpress® Highlights New Materials, a 24-Hour Replacement Solution at IFPE

Freudenberg Xpress®, the company’s service for manufacturing replacement parts, prototypes and small production runs of seals, can produce large and small one-off components in as little as a day. Using a variety of advanced materials and manufacturing techniques, Freudenberg Xpress® can provide industrial customers with fast, economical, tailor-made sealing solutions that do not compromise quality or safety standards.

During the IFPE show, Freudenberg Xpress® will showcase components made of some of the highest quality materials in the world. The company’s exclusive, best-in-class, Freudenberg polyurethane, 94 AU 30000, for example, was developed primarily to handle fluid power challenges such as more aggressive environments, higher temperatures and longer operating hours.

94 AU 30000 is more resistant to water and synthetic hydraulic fluids and withstands major temperature fluctuations better than other existing polyurethane materials. The material offers excellent performance in heat and cold and can be used in mineral hydraulic fluids at temperatures ranging from -31°F (-35°C) up to 248°F (120°C).

Freudenberg’s new polyurethane also performs well under pressure, said Stefan Boeseneilers, Manager, Freudenberg Xpress®, Americas. In comparison tests with various extrusion gaps and pressures, seals made with this material show no appreciable signs of wear while conventional seals malfunction prematurely. Tear strength surpasses other polyurethanes and the material doubles extrusion stability thus avoiding damage caused by the peaks in pressure commonly experienced in heavy duty equipment.

“94 AU 30000 has multiple applications, and you can only get it from Freudenberg,” Boeseneilers said. “Fluid Power customers, in particular, will benefit from this material’s unique properties. Customers no longer need to buy many different materials to meet their sealing needs. We can meet their replacement and prototype needs quickly, precisely and with this world-class material.”

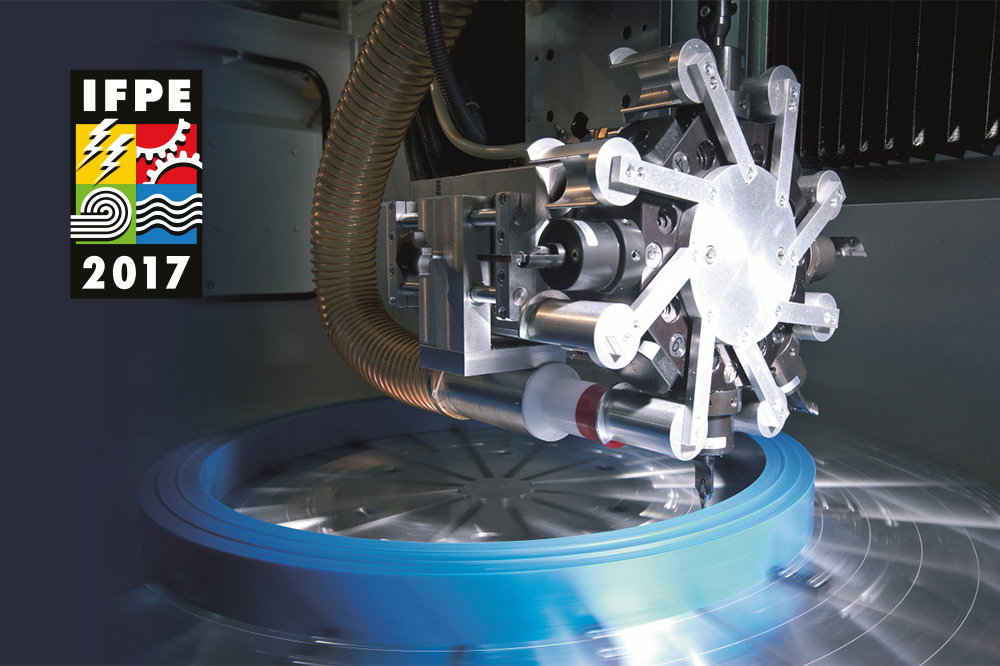

The company has also invested in new manufacturing capabilities that facilitate 24-hour-production of complex seals as large as five feet (1.8 m) in diameter. A gigantic state-of-the-art CNC lathe incorporates new milling functions which greatly expand the production capabilities of Freudenberg Xpress® to manufacture seals with complex geometries and features, Boeseneilers said. For example, the organization can now produce seals with complex geometries and features such as oval cuttings, holes on the seal circumference, hexagonal and rectangular shapes or virtually any other shape a customer needs thanks to the additional milling function of the machine.

“Our customers have been asking for this kind of advance capability, and we now provide it in an extremely timely and precise manner,” Boeseneilers said. “Thanks to this new lathe, we can easily accommodate seal variations and rapidly manufacture sophisticated, globally-certified sealing components for Xpress customers.”

Freudenberg Xpress® components will be on display at the company’s IFPE booth (#82630) March 7-11. For more information about Freudenberg at the IFPE, please visit the company’s Microsite https://ifpe.fst.com or its Twitter channel https://twitter.com/Freudenberg_FST.

Cheryl Eberwein

Director, Corporate Communications

Telephone: +1 734 354 5373

cheryl.eberwein@fnst.comDownload Documents

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!Further Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.