Aerospace

Commercial Aviation - Shaping the Future of Commercial Flying

What are the current challenges for aircraft seals in commercial aviation?

The aviation industry is one of the most innovative sectors in the world. It connects people and markets, but faces unprecedented challenges: Commercial aircraft must become more efficient, lighter and more sustainable to meet the demands of the future. At the same time, expectations for safety, reliability and cost optimization are rising.

Freudenberg Sealing Technologies is at the forefront of this transformation with state-of-the-art sealing and materials solutions. With a comprehensive product portfolio, unrivaled materials expertise and a deep understanding of the aviation industry, Freudenberg Sealing Technologies is actively shaping the future of commercial flight.

What are the Challenges Facing the Aviation Industry?

The aviation industry is facing a variety of challenges that include technological, regulatory, economic and sustainability aspects. These requirements call for new approaches and reliable solutions.

Technical loads

The engines and systems of modern commercial aircraft have to withstand extreme physical stresses. These include high temperatures in engines, which require maximum efficiency, as well as high pressures in compressors and hydraulic systems, which demand maximum precision and reliability. In addition, seals and materials must permanently withstand aggressive substances such as AV-Gas, Jet-A, SAF fuels, hydraulic fluids and de-icing agents.

What regulatory requirements are there in commercial aviation?

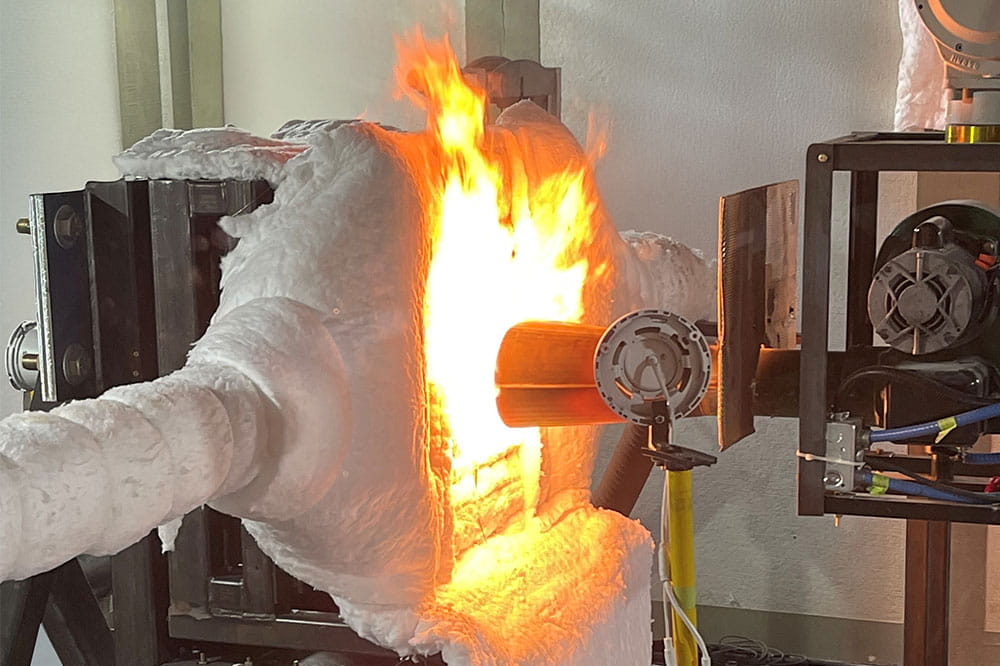

Aviation is regulated by strict standards and test procedures that ensure the highest safety and quality standards. International certifications such as AS9100, EN9100 or the REACH regulation are mandatory in order to meet global requirements. Fire protection tests in accordance with ISO 2685 and AC20-135 verifies that materials and components withstand defined exposure to flame and heat. For elastomer seals, this typically involves resistance to temperatures up to 325°C, ensuring reliable performance under realistic operational conditions.

Certifications and standards:

1. AS9100/EN9100: Quality management in aviation.

- Comprehensively regulates the quality requirements for the aerospace industry.

- Freudenberg Sealing Technologies is certified according to these standards, guaranteeing customers consistent quality.

2. ISO 2685 and AC20-135: Fire protection in aviation.

- Defines requirements for materials and components that are exposed to extreme heat and flames.

3. AMS, EN, NFL standards (Aerospace Material Specifications):

- Compliance with numerous AMS standards ensures broad material and part capabilities for aerospace sealing applications.

- Covers a wide variety of elastomers, thermoplastics, and composite materials tailored for demanding aerospace conditions.

4. Nadcap: Accreditation program for aviation suppliers.

- Freudenberg Sealing Technologies is Nadcap-certified and thus fulfills the strictest requirements for manufacturing and testing processes.

5. REACH and RoHS: Environmental protection standards.

- Ensure the use of environmentally friendly and safe materials.

6. ITAR Capabilities:

- Our processes and facilities include compliance with ITAR (International Traffic in Arms Regulations), highlighting our capability to meet stringent regulatory and export control requirements.

Economic requirements

The efficiency and reliability of all systems are crucial to minimize operating costs. In particular, unplanned maintenance that causes an Aircraft on Ground (AOG) represents an enormous economic risk. Such situations can ground aircraft and cause high costs. Durable seals and reliable materials help to avoid AOG cases and maximize aircraft availability.

Sustainability requirements

The industry is increasingly demanding environmentally friendly and efficient solutions. Lightweight, durable materials lower fuel consumption and significantly reduce CO₂ emissions. In addition, the use of sustainable aviation fuels (SAF) and hydrogen-based propulsion systems requires new materials that meet these requirements and enable environmentally conscious aviation.

Why Freudenberg Sealing Technologies?

Freudenberg Sealing Technologies is the world's leading supplier of engineered sealing solutions. With over 175 years of experience in engineering and material development, we are a reliable development and service partner for the aviation industry. Our mission is to meet our customers' stringent requirements and exceed their expectations with pioneering, durable and sustainable solutions.

Freudenberg Sealing Technologies: Expertise for the Aviation Industry

Aircraft come in a wide variety of shapes and sizes - a challenge that we meet with our standard seals as well as with customized solutions. As a leading supplier of sealing solutions, Freudenberg Sealing Technologies offers a wide range of options to meet the diverse requirements of the aviation industry.

With one of the world's largest product portfolios, world-class engineering and unrivaled material development, our customers rely on us to provide the optimal sealing solution for every application - from engine seals and flight control systems to airframe and landing gear seals.

With decades of experience and a broad product portfolio, Freudenberg Sealing Technologies is the ideal partner for the complex challenges of civil aviation. Our expertise extends far beyond sealing solutions - we create real added value for our customers through:

Technology and Innovation

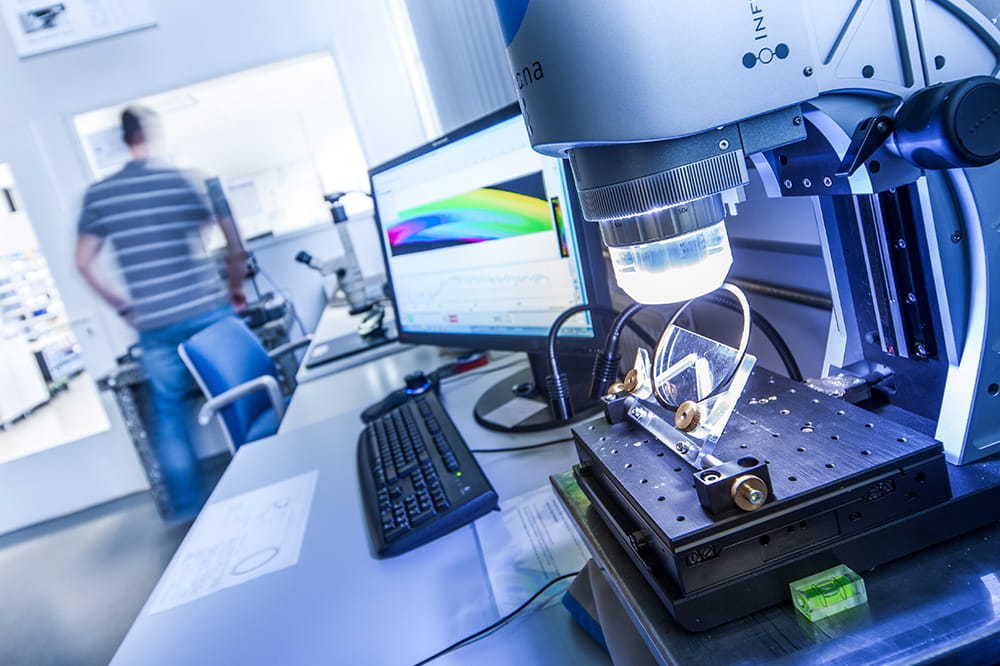

We combine state-of-the-art development tools such as finite element analysis (FEA) with in-depth engineering knowledge to deliver precise and reliable solutions.

Sustainability and Efficiency

Our innovative approaches lower fuel consumption, reduce emissions and enable the integration of sustainable aviation fuels.

Customized Solutions

Whether for extreme temperatures, aggressive media or high mechanical loads - we develop seals that are perfectly tailored to the requirements of your applications.

Minimization of Downtimes (Aircraft On Ground [AOG])

The durability and reliability of our seals prevent unforeseen failures and reduce operating costs.

Optimized Maintenance Intervals

Materials and designs from Freudenberg Sealing Technologies reduce maintenance requirements and ensure smooth operation.

Flexibility and Partnership

We work closely with our customers to understand individual requirements and deliver customized solutions that create real added value.

Your Solutions at a Glance

The aviation industry demands specialized sealing solutions for complex applications in commercial aircraft. Freudenberg Sealing Technologies develops pioneering products and materials that overcome specific challenges while supporting safety, efficiency and sustainability.

Seals for Engines, Auxiliary Power Units (APU), Nacelles and Pylons

Reliable, fireproof solutions providing exceptional protection against flame exposure and extreme thermal conditions in engines.

More details chevron_right

Sealing Solutions for Flight Control Systems and Transmissions

Safe and efficient seals and materials for flight controls and transmissions in commercial aviation.

More details chevron_rightServices for Aerospace

News & Stories about Aerospace

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new